Keys to Effective Monitoring for Listeria

The Food Safety Modernization Act was passed nearly a decade ago, and as of last year, all food processors are required to be compliant with the act’s Preventive Controls for Human Foods regulation. Being compliant involves performing, under the guidance of a preventive controls-qualified individual, a Hazard Analysis of the facility, ingredients, process, and products; defining the appropriate preventive controls for the identified hazards with the relevant recall plans; and verifying the implementation of those controls and plans. For ready-to-eat (RTE) food processors, for whom contamination of the food by the bacterial pathogen Listeria monocytogenes from the environment is a likely and foreseeable hazard, this has meant developing and implementing pathogen environmental monitoring (PEM) programs as part of their sanitation controls.[1] For many RTE processors, this can seem a daunting undertaking, and even for processors with established PEM programs, ensuring that those programs are effective is a daily challenge. Do not despair; with diligence, training, and a proactive attitude, you can build and maintain an effective PEM program.

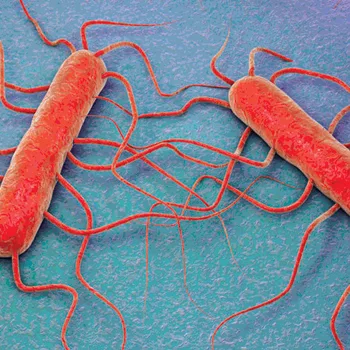

What Is Listeria monocytogenes?

L. monocytogenes is a Gram-positive, rod-shaped bacterium. L. monocytogenes has been isolated from the pristine soils of the Catskill Mountains to the bustling sidewalks of New York City; it is ubiquitous in our environment. L. monocytogenes is not the fastest grower and does not do well competing with other bacteria. Unlike many bacterial competitors, though, Listeria does grow well in the cold and even better when that environment is also wet and filled with nutrients. When we think about our RTE processing areas, we remove L. monocytogenes and the competition with each cleaning and sanitation cycle. We then keep the environment cold to maintain product quality, and when we start processing, we create a wet and nutritious situation that is ripe for any L. monocytogenes lurking in hard-to-clean places or hitchhiking on an employee’s shoe. This is why hygiene and sanitation programs are so important for controlling routes of transmission into our processing environments, and why PEM programs are critical to helping us root out L. monocytogenes within the processing environment.

L. monocytogenes is one of 17 species in the genus Listeria, which includes L. innocua and L. cornellensis. These other species grow well under the same environmental conditions as L. monocytogenes, making them useful for identifying areas that could support the unwanted pathogen. Thus, many PEM programs use microbiological tests that look for the entire genus to find potential problem sites before they provide harborage to L. monocytogenes.

Building a PEM Program

One of the foundational steps of a PEM program is classifying the processing environment into zones in relation to the proximity and risk of contamination to the food being made. Typically, we break our processing environment up into four zones: Zone 1 comprises food contact surfaces—any piece of equipment that comes in contact with the food. Zone 2 consists of nonfood contact surfaces near the food or food contact surfaces—things like the underside of tables, the exterior of processing equipment, control panels, and refrigeration units. Zone 3 encompasses more remote nonfood contact surfaces located in or near the processing area—drains, walls, floors, forklifts, carts, and air vents. Lastly, zone 4 takes us outside the processing area, covering nonfood contact surfaces in locker rooms, offices, shipping docks, maintenance areas, and other storage areas. The majority of swabs will be focused on the high-risk zones, but all zones must be monitored to understand where L. monocytogenes is harbored in the facility. Sometimes, assigning a surface to a zone takes extra attention. For example, the frame of a specific piece of process equipment when the food safety team is passing through at the end of the day may look like a zone 2, but if observed during processing, it would be noted that condensate forms on the frame and drips onto exposed food or a food contact surface, and thus is also actually a zone 1. Likewise, drains directly under food contact surfaces may be classified as zone 2 rather than zone 3 to account for the proximity and risk to the food during processing.

Processors will need to select sites for testing and ensure that each site has a clear descriptor and ID so that they can be consistently tracked. To select these sites, the team of employees responsible for the PEM will need to walk through the processing facility with an eye out for potential harborage sites and areas of high traffic. It is also important to do multiple walk-throughs at different times of the day to not miss any important changes or conditions. The goal is to think like L. monocytogenes and look for places that are protected from cleaning, are potentially kept cold and wet, and have leftover “food.” At the end of this exercise, the food safety team should have a master list of all the possible sites. The question of how many sites a processor should have really depends on the size and condition of the facility and equipment. It’s not unheard of for a midsize facility to have identified upward of 500 sites. Keep in mind that all the sites on the list do not need to be tested at the same time, and the list itself should not be written in stone. The employees responsible for testing should have the freedom to add sites that appear during their rounds, like if they spot cracks on a piece of equipment or an unexpected backup in a drain. The master list also must be regularly reviewed and updated whenever new pieces of equipment are added or old ones discarded, as these events can not only introduce new harborage sites but also could change the site’s zone classification.

Once all the sites are mapped out, it’s time to start implementing a swabbing regime. Common questions are: how many swabs should a processor perform, when should they be done, and how often should they be taken? The common response is that it depends on the risk. Just like when identifying the sites, the number of processing lines, condition of the facility and equipment, traffic flow, and frequency of operation all factor into the equation. The U.S. Food and Drug Administration (FDA)’s current draft guidance The Control of Listeria monocytogenes in Ready-To-Eat Foods[2] recommends that even the smallest RTE processors swab at least five food contact surfaces and five nonfood contact surfaces per production line. Ideally, these swabs are taken 3 to 4 hours into the production run or just before the end. This provides the best opportunity due to the time, temperature, and available nutrients for L. monocytogenes, if it’s lurking, to grow to levels where it can more readily be detected. As for frequency, large operators may be swabbing weekly, whereas small processors operating only a few days a week may be able to justify a less-frequent regime. There are reasons to swab at different times; for example, to verify the efficacy of your cleaning and sanitation, or to evaluate whether certain events like construction or weather-related damage have changed the potential distribution of L. monocytogenes in your facility. The point is to be proactive in the search for L. monocytogenes so you are not surprised later.

You Found a Positive; Now What?

The common adage about L. monocytogenes is “If you haven’t found it, you’re not looking hard enough,” which means you will get positives from time to time. Do not freak out; have a plan for how to address it. Documented deep-cleaning procedures for an area that tests positive are key, as is following up with more frequent monitoring of that site to ensure that whatever action was taken was sufficient to remove L. monocytogenes. If additional or intermittent positives occur at a given site, vector swabbing is a valuable practice to help identify the true source of contamination. Vector swabbing involves adding swab points to the area around where the positive site is located. This could be nearby drains, overhead pipes/ceiling, wall/floor junctions, feet/undersides of equipment, or nearby foot-traffic areas. For example, a floor drain may intermittently test positive, and one might think the drain itself is the hard-to-clean harborage site, when in fact the true source is a crack where the floor meets a structural column a few feet away. The crack is hard to see by the cleaning crew, it traps food particulates, and it doesn’t dry rapidly. When L. monocytogenes levels get high enough and the column gets wet, it disturbs the harborage site, releasing L. monocytogenes into the environment and down the drain where the swabbing program can detect it. Vector swabbing can help processors identify these problem areas, allowing for corrective actions to be identified, like sealing the crack, thus removing the harborage point and correcting the problem. It is important to document these corrective actions for positive sites, and if a problem persists, do not be reluctant to ask for outside help. There are private consultants and university food safety Extension professionals who either have the needed expertise or know someone who does in your facility’s food production category and can help you root out the problem.

Swabbing programs looking for the presence or absence of Listeria help identify harborage spots, but there is always the challenge of figuring out whether what appears to be intermittent positives are due to transient L. monocytogenes hitchhiking on a random employee’s shoe or are a deeper, more persistent problem that you only occasionally catch a glimpse of. The cost of DNA-based detection methods has dropped significantly in the past 5 years, and performing whole-genome sequencing (WGS) of environmental positives to develop molecular fingerprints so that processors can compare isolates is no longer out of the question. Soon it may become routine. In our previous vector-swabbing example, WGS of the positive isolates could allow a processor to confirm that the L. monocytogenes strain found at the column was the same as that found in the drain and feel confident that the problem was addressed correctly. If the strains turned out to be different, it would help the processor realize there were multiple problems to address rather than being caught by surprise later. Using WGS over time, processors can build a catalog of all the L. monocytogenes strains they encounter and see if certain strains turn out to be persistent problems in the environment; if so, added steps may be needed to address the problem. This may seem like extra credit, but it’s important for processors to think about how they can incorporate strain tracking into their PEM programs. Just this spring, FDA revisited an RTE processor and sent a warning letter stating that their procedures were inadequate to significantly control L. monocytogenes in their facility. FDA justified this not only because their visits had found multiple environmental positives over the past 3 years, but also because WGS had shown that the same strain was present over several years. Thus, the processors had not effectively removed a resident pathogen that had also matched a clinical isolate from someone who had been sick. Managing a PEM program that incorporates WGS is not simple, but building those capabilities is a prudent exercise for RTE processors looking to protect their consumers and their business.

Conclusions

PEM programs that effectively control L. monocytogenes are not built overnight. They begin with written Good Manufacturing Practices, then implement hygiene and sanitation programs and proactive PEM swabbing programs. They require a commitment to review, interpret, and respond to the data. These programs cannot be built by a single person alone; they require teams of individuals from across departments and levels within the facility, as well as members from outside the business. As RTE processors start or strengthen their current programs, they should remember there are resources to help. Regional food safety Extension specialists are just an email away for advice, and there are PEM training programs available at academic institutions across the country, like here at Cornell University, plus industry-specific organizations like the International Dairy Foods Association. Ideally, working together, we can build industry-wide PEM programs and practices that support the health of both consumers and our businesses.

Samuel D. Alcaine, Ph.D., is an assistant professor in the Department of Food Science at Cornell University.

References

1. www.3m.com/3M/en_US/food-safety-us/resources/education/environmental-monitoring/.

2. www.fda.gov/regulatory-information/search-fda-guidance-documents/draft-guidance-industry-control-listeria-monocytogenes-ready-eat-foods.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →