Monitoring Volatile Organic Compounds in Beer Production Using the Clarus SQ 8 GC/MS and TurboMatrix Headspace Trap Systems

Beer is a popular beverage produced by the fermentation of hopped malt extracted from barley and other grains. Although simple in concept, beer is a highly complex mixture of many compounds, including sugars, proteins, alcohols, esters, acids, ketones, acids and terpenes. Flavor is an important quality of any beer and the chemical content of the beer is obviously responsible for that flavor. Aroma is an extremely important part of the flavor, so there is a strong interest by brewers in the volatile organic compounds (VOCs) in beer that affect its aroma.

Some VOCs have a positive effect on aroma (attributes) and some have a negative effect (defects). The ability to characterize these in beer products before, during and after fermentation would be an important tool in process control, quality assurance and product development.

This application note describes a system comprising a headspace trap sampler to extract and concentrate VOCs from a beer sample and deliver them to gas chromatography/mass spectrometry (GC/MS) for separation, identification and quantification.

The purpose of our experiments is to demonstrate that attributes and defects can all be monitored using one detector and from a single injection with MS. The associated benefits include a quicker return on investment, enhanced productivity, more information from a single analysis, and less bench space requirements.

Instrumentation

In this analysis, we utilized a headspace trap system for sample introduction to characterize the flavor of beer. This technique ensures that non-volatile material in beer does not enter the analytical system, which can cause system contamination. The headspace trap extracts the volatile components from a large sample and focuses them onto an inline adsorbent trap. It also facilitates very easy sample preparation—a volume of beer is dispensed into a vial and sealed. The subsequent analysis is then fully automated.

A PerkinElmer® TurboMatrix™ Headspace Trap connected to a PerkinElmer Clarus® SQ 8 GC/MS was used for these experiments. Using a headspace trap instead of the classical headspace technique enables up to 100-times improved detection limits over classical headspace methods.

A slightly polar 60 m × 0.25 mm × 1.0 μm Elite 5 (5% phenyl-silicone) column was used. This thick-film column provided sufficient retention to separate the early-eluting most volatile components and provided the dynamic range necessary to chromatograph both high- and low-level components in the beer.

Experimental

Overview

Several experiments were performed that are key to the brewing industry:

• Quantitation of dimethyl sulfide (DMS), 2,3-butanedione (diacetyl), 2,3-pentandione and t-2-nonenal.

• Characterization of several types of beers

• Fermentation profiling

• Analysis of raw materials

• Aging studies

Analytical Method

The experimental conditions for this analysis are given in Tables 1 to 4.

Calibration

A 10-point calibration was prepared for four target ‘defect’ compounds. The detection limit goal was 5.0 parts per billion (ng/mL). The standards were acquired in simultaneous full scan and single ion monitoring acquisitions (SIFI). Examples of the chromatographic peaks and their signal to noise ratios at the 5.0 ppb level are given in Figures 1 to 4.

.jpg)

The calibration results are presented in Table 5. An example of one of the calibration plots is given in Figure 5. These data demonstrate a good linear response for these components in at low levels in a highly complex matrix.

Characterization of Beer

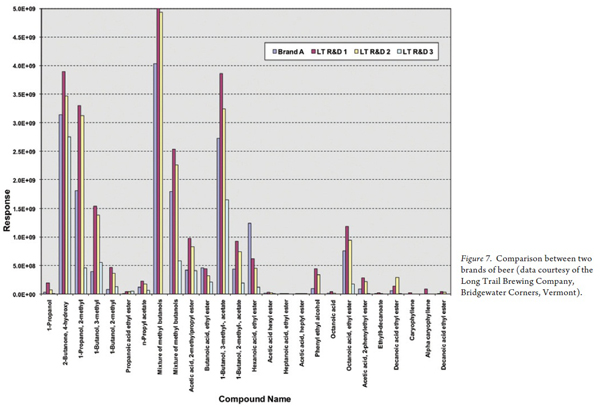

The MS detector enables the identification of components in beer. Figure 6 is an example of such characterization that was analyzed in our research center in Shelton, CT. Figure 7 is a comparison of the component identities and responses found in two competitive products.

Figure 8 shows the results of a research study comparing the flavor profiles of a beer from five different fermentations.

Figure 8 shows the results of a research study comparing the flavor profiles of a beer from five different fermentations.

Fermentation Process

This analyzer provides the ability to obtain analytical results during the fermentation process.

An experimental batch of American pale ale was brewed and fermentation initiated. A sample was analyzed every 8 hours starting with time zero and completing on day 8.

Specific gravity is often used as an indicator of the fermentation progress and is shown for this beer in Figure 9. The final gravity of 1.012 was achieved in about 100 hours.

Specific gravity is often used as an indicator of the fermentation progress and is shown for this beer in Figure 9. The final gravity of 1.012 was achieved in about 100 hours.

The concentrations of key components in the beer were checked during the fermentation process. The profiles of two key ‘defects’, 2,3-butanedione and dimethyl sulfide are shown in Figures 10 and 11, respectively. Trans-2-nonenal was not detected.

Analysis of Raw Materials

Analysis of Raw Materials

Figure 12 displays the results of a study comparing the components of different hops in order to understand and to improve the taste of beer. Some beers use adjuncts to impact special flavors. The same system may be used to characterize these. Figure 13 displays the results of a comparison of orange peel from different suppliers for use in Belgian-style beers.

Aging Studies

Beer is a very complex matrix that ages over time due to chemical and biological activity so storage conditions are critical to its quality.

Exposure to air promotes the formation of aldehydes and other undesirable compounds that can impair the flavor of a good beer. The Clarus system is capable of monitoring such compounds. A compound of major concern is t-2-nonenal (‘wet cardboard’ flavor), which we monitored during the fermentation studies, yet was undetected.

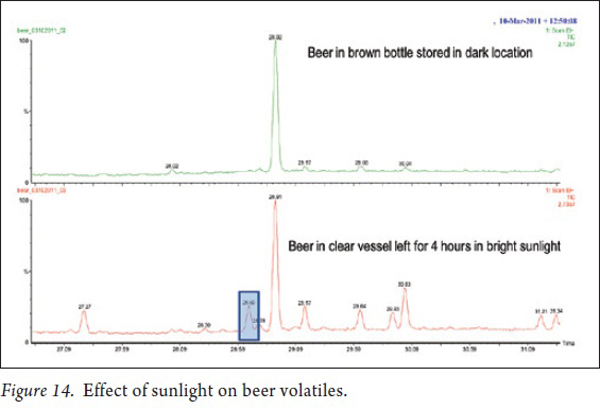

Another flavor concern is that bittering components (isohumolones) react to light and produce mercaptans and other volatile sulfur compounds giving a ‘skunky’ flavor to the beer. Figure 14 shows chromatograms of the same beer kept in the dark or in bright sunlight. Major differences in the composition of the beer VOCs are apparent. Figure 15 identifies one of the sun-stuck components as an olefinic thiophene.

Another flavor concern is that bittering components (isohumolones) react to light and produce mercaptans and other volatile sulfur compounds giving a ‘skunky’ flavor to the beer. Figure 14 shows chromatograms of the same beer kept in the dark or in bright sunlight. Major differences in the composition of the beer VOCs are apparent. Figure 15 identifies one of the sun-stuck components as an olefinic thiophene.

Conclusion

The combination of the TurboMatrix HS Trap extraction technology with the state of the art Clarus SQ 8 GC/MS is a very powerful, yet easy to use tool for investigating many aspects of the beer production process. Virtually anything that is volatile and organic can be monitored in beer using a single column and applied conditions. The system may be deployed for checking raw materials, monitoring fermentation, quality control testing of a final product, product development, aging studies and trouble shooting.

Traditionally, this work would have been performed by skilled tasters, which of course continues to be an important part of any brewing process. The opportunity to compliment taste and olfactory determinations with hard objective analytical data can only enhance the art of making quality beer.

In this note, we have conducted many of the critical analyses relevant to beer brewing. We have shown good performance in determining levels of defects such as diacetyl and dimethyl sulfide. We have identified flavor components in the beer, hops and adjuncts.

All this is possible on a system that simply requires the beer to be sealed in a vial and placed on an autosampler tray. The system does the rest.

We thank Bill Yawney, the QC Manager, from Long Trail Brewing Company for allowing us to use some of his data in this application note. In addition, Bill provided us with valuable expert advice on the brewing process and the analysis of beer.

Lee Marotta is a senior field application scientist and Andrew Tipler is a senior scientist at PerkinElmer.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →