COVID-19

Coca-Cola bottlers produce millions of COVID-19 test tubes

Plastic preforms used for bottles are just the right shape for test kit swabs

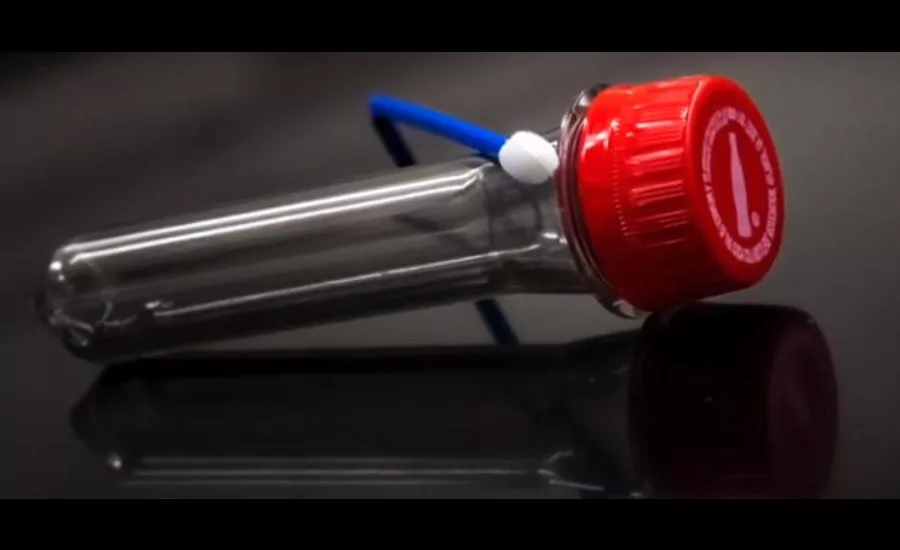

While the red branded lids were used during development, the tubes for testing labs will have plain white screw-top caps that are tamperproof and prevent leakage.

A Coca-Cola Consolidated bottling facility can produce 7 million COVID-19 test tubes a week.

Photos courtesy of Coca-Cola Consolidated

A federal lab helping scale up production of COVID-19 test tubes found a solution in the beverage industry: the plastic used for Coca-Cola bottles.

The finished bottles themselves aren’t being used, but the PET preforms, which would normally be blown into bottle form, are conveniently the same shape as a test tube used to hold a swab with a sample from a person.

Coca-Cola Consolidated Inc., the largest bottler of the brand in the U.S., says a facility in Charlotte, N.C., managed by a group of bottlers has produced more than 7 million tubes already for test kits, using the preforms.

And that’s the number of tubes that Southeastern Container, a PET preform and bottle manufacturing cooperative, can produce weekly. During the testing phase, the sample tubes were topped with the familiar red Coke caps, but the tubes produced for tests will have plain white screw-top caps that are tamper proof, preventing leakage and exposure during transport. Soda bottle preforms are the perfect size to hold the long COVID-19 swab in saline solution during transport.

The Oak Ridge National Lab considered several options when helping the U.S. Department of Health and Human Services identify manufacturers that could help fill a gap in collection tubes needed for states’ increased testing.

“Through a personal connection and discussions with Coca-Cola Consolidated, we determined the preform that goes into a blow molding machine to make Coca-Cola bottles looked exactly like the test tube needed for the COVID-19 testing kits,” says Lonnie Love, lead scientist for Oak Ridge National Laboratory’s COVID-19 advanced manufacturing initiatives. UT-Battelle manages the lab for the Department of Energy’s Office of Science.

The laboratory worked with COVID-19 testing company Longhorn Vaccines and Diagnostics to confirm that samples from Coca-Cola Consolidated could work to help with a global shortage of cryotubes.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

“Coke bottlers have done what no other vialing company could do: In a few short days, they have fabricated a small, ruggedized vial from a plastic preform that does not leak, is large enough to hold any swab type, and importantly, they can make millions of tubes per week,” says Luke T. Daum, chief scientific officer at Longhorn Vaccines.

The Coca-Cola bottlers will now supply millions of preforms for test kits throughout the country, with five testing companies in line at this point to start using the containers.

Once test tubes are produced, sterilization is usually required before they can be used in test kits. Sandia National Laboratories, a Department of Energy and National Nuclear Security Administration lab with headquarters in Albuquerque, N.M., is using its Gamma Irradiation Facility and a team of radiation science experts to find the right level of gamma radiation to sterilize the tubes without damaging the plastic or seals.