Choosing a Package Designer Who Understands Federal Regulations

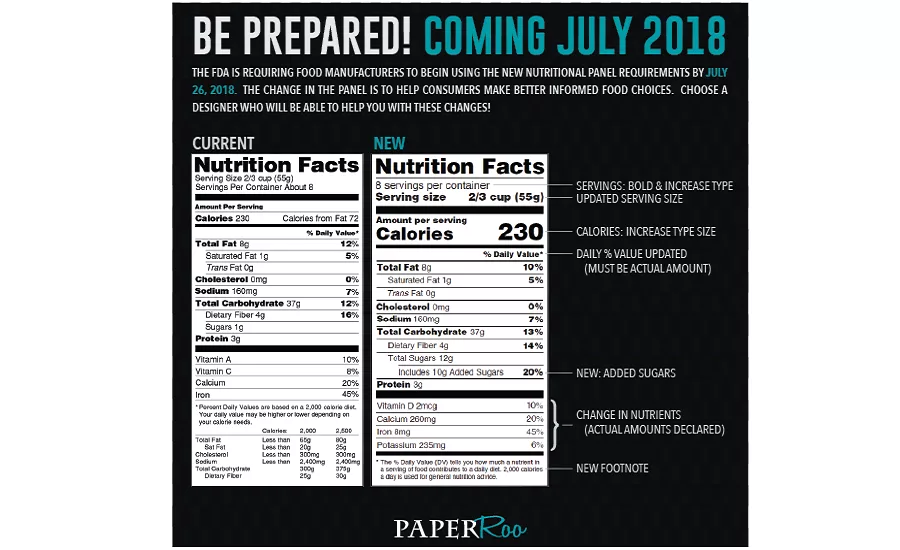

Mastering the complexities of food and drug manufacturing can be a challenge. The FDA and U.S. Department of Agriculture can cause concern in the minds of food and drug manufacturers and co-packers. Although these government agencies might be considered demanding at times, they play an important role that ensures there are procedures to protect the safety of the American public.

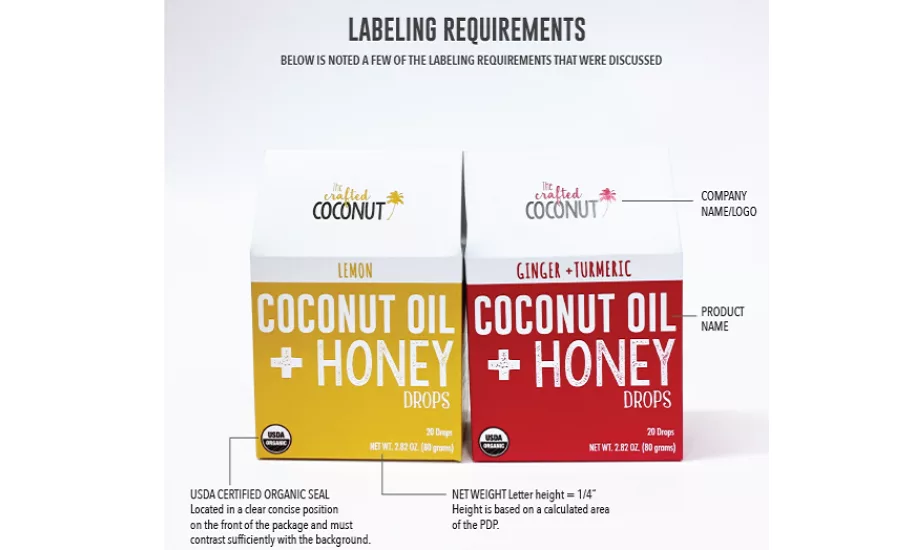

There is an overwhelming amount of project planning and sourcing that goes on in the background of developing a product. Packaging is a large part of that process, which is also highly regulated by the FDA and USDA. As defined by the FDA and USDA Food and Labeling Guide, the design of product packaging is referred to as “labeling” no matter if it is a box, bag or a physical label being applied to a package.

The FDA and USDA regulations are just a guide. You can use an alternative approach if the approach satisfies the requirements of the regulations. Pretty vague, right? The theory behind the labeling regulations is to maintain consistency across all food and drug product brands so that the consumer is aware of exactly what they are purchasing. When consumers buy products such as foods, there are some basic elements found on every package. Net Weight located on the principle display panel (PDP), properly defined product names, government seals such as USDA Certified Organic, the nutritional panel and ingredient statement, just to name a few. All of these elements are placed in specific areas of the package, at a specific size, based on a calculation of the overall package size. Choosing a graphic package designer who fully understands these regulations is what every manufacturer should be looking for.

Designers Have a Dual Role

Educators often mold the minds of graphic packaging designers to focus on the aesthetics of the brand and create artwork that will build a long-lasting visual relationship with the consumer that ultimately results in the purchase of the product. Yes, marketing and brand recognition play a significant role in process of package design. However, more than just the design, there is a substantial amount of FDA and USDA regulation guidelines that dictate how the design is to be placed on the package.

Most often, graphic package designers as well as manufacturers are either completely unaware of the regulations or each assumes the other party will take on the responsibility of assuring regulations are met. When those regulations are not met, there can be a huge impact on timelines and costs.

Like anything else, designing packaging takes time. In many instances, the overall project plan allots less time than actually needed to design the package. However, if the packaging is not designed with these regulations in mind, a road block in the process may result in timelines being pushed. Timelines being pushed directly affects getting the product on the shelf, which results in profit loss. Having a graphic package designer with FDA and USDA knowledge will ensure all of these guidelines are met. .

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

Right Design First Time

If you work as a graphic package designer, you often hear the budget is tight. There are many ways to save on packaging costs. One way is to do it right the first time. Time is money. Jumping back and forth in editing due to lack of regulation knowledge, costs money. Giving the thumbs up to print the box or bag for the product, only to find out after everything has been printed, that the net weight statement was not properly sized as stated in the regulations, costs money.

When the product hits the shelf and the FDA or USDA flags a package as “not complying with the Labeling regulations and Guidelines” who is responsible? The food or drug manufacturer. At the very least, the goal is to avoid the potential for time and profit loss. Working directly with a package designer who fully understands the intricacies of the business from product branding and packaging to shelf impact as well as all the government FDA and USDA regulations is what every manufacturer should be striving for in a designer.

This article was originally posted on www.brandpackaging.com.