Controlled Environment Agriculture: A Systematic Review

The intensification of indoor agricultural systems must be achieved by specific processes that minimize negative impacts on the environment and place food safety front and center

Despite constant efforts to increase crop yield, traditional agriculture is no longer sustainable for future generations. This method of farming generates a considerable amount of food waste, fertilizer leaching, and fertilizer runoff. It also requires greater land space and more water to meet growing demand for food, while crop production continues to be impacted by unpredictable weather patterns. There has been a growing interest in controlled environment agriculture (CEA) due to a relatively recent surge in the popularity of locally sourced produce. This approach can provide year-round production, utilize resources in an efficient manner, and, in many instances, reduce the carbon footprint associated with transporting food over long distances.1,2,3,4

CEA production systems can be highly suitable for commercial urban food production, especially in settings where land availability and costs are a challenge. Soilless culture methods, such as hydroponics, allow for the growth of plants in non-traditional spaces. These systems can optimize the use of water and nutrients by recirculating liquid solutions and, therefore, reduce waste. Future food requirements can be met by intensifying indoor agriculture systems, such as greenhouses and vertical farms. However, this objective must be achieved by specific processes that minimize negative impacts on the environment and place food safety front and center.1,4

CEA Description, Concepts, and Limitations

CEA is a precision-driven technological method of agriculture that involves controlling several environmental and growth conditions in order to maximize yields in a relatively small footprint. This includes extending growing seasons into possible year-round production. The following variables can be manipulated in a more direct way when compared with traditional systems: lighting, temperature, carbon dioxide levels, relative humidity, moisture content, nutrient composition, and electrical conductivity of a nutrient solution.

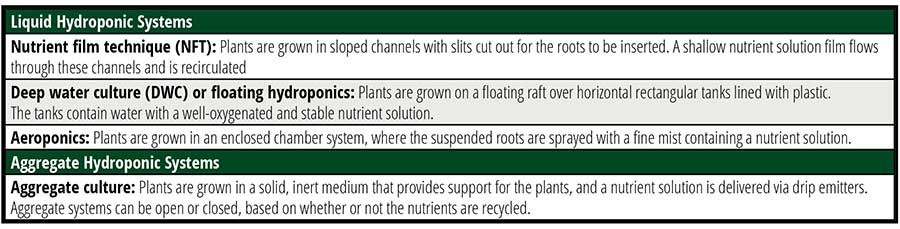

The specific technologies that are utilized to obtain the appropriate conditions for efficient production of a given commodity can vary between different CEA systems. The indoor controlled environment category includes urban agriculture, vertical agriculture, and indoor farming, as well as insect farming, fish farming (aquaponics), and laboratory-grown meat. Hydroponics and aquaponics are innovative techniques that can be used in most of these cases. Hydroponics is a process where a dilute nutrient solution is applied to a soilless agricultural system, such as a thin film solution or rockwool. Nutrient film technique (NFT), deep water culture (DWC), aeroponics, and aggregate culture are the most commonly used hydroponic systems (Table 1). Aquaponics is a process where water and fish/crustacean waste are converted into nutrient solutions for plant production in a hydroponic system.1,3,5,6

A slow and steady industry shift has been seen from traditional greenhouses to innovative controlled systems, with the help from extensive research that provides a clearer pathway toward the feasible application of scientific concepts. This novel approach relies on energy-efficient internet of things (IoT) sensors and instruments, digital communication devices, structural design, and simulation models that imitate the behavior of growing areas. Sensors are often used to monitor various environmental conditions, where the collected data is transmitted to a computer to activate control measures that include heating, lighting, and ventilation. Light-emitting diodes (LED) have become very popular in indoor farming systems, particularly in recent years due to the many benefits they offer over traditional light sources. These can be customized to provide the optimal spectrum of light for different stages of plant growth and development, are more energy-efficient, and have a longer lifespan.3,5,9

CEA continues to be a promising system, although it is still in the early stages of commercialization with some room for growth in the research and development sector. The initial investment is considerable due to being a high-technology and energy-intensive system, which could be offset by further penetration into niche markets, such as organic and local production, that can include sustainability initiatives. Heirloom tomatoes, leafy greens, and micro-greens have high profit margins, which continue to be an attractive revenue stream for suppliers that use advanced agricultural systems. There is a segment of customers that is willing to pay and then charge a premium for these commodities.1,6,10

Food Safety

CEA systems have an evident food safety advantage compared to traditional growing methods due to their protection or isolation from the outside environment, which includes soil, wild/domestic animals, and weather events. Nevertheless, there are entry points for pathogens through workers, water, seeds, substrates, and nutrients. It is common for these operations to recirculate water and nutrients, which can provide a pathway of initial pathogen contamination and quick transmission. In general, direct or indirect product contamination is possible during all stages of the supply chain such as production, harvest, processing, storage, distribution, retail, and processing.1,11

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

This contrast in risk level can be exemplified by the following two food safety events:

- A 2019 outbreak of Escherichia coli O157:H7 in romaine lettuce from the Salinas Valley growing region, where greenhouse-grown romaine or product labeled as "indoor grown" was not implicated. In this case, only open field lettuce in that region was considered as the contamination source.11

- A 2021 BrightFarms Packaged Salad Greens recall in Illinois, Indiana, Iowa, Michigan, and Wisconsin that was linked to a Salmonella Typhimurium outbreak. Between July and August 2021, the U.S. Food and Drug Administration (FDA) carried out an investigation into this CEA hydroponic operation and observed issues pertaining to improper growth media storage; an unacceptable water test result from an active pond (which was found positive for a different Salmonella serotype); lack of cross-contamination control between leaf harvesting operations and production water; and failure to properly record the regular cleaning and sanitization of equipment, tools, and buildings in accordance with established procedures, among other deviations.12

The CEA Food Safety Coalition—recently renamed the CEA Alliance—was created by industry leaders in 2019 after numerous food safety events involving romaine lettuce. Its main objective is to support indoor-grown commodities through research and development, as well as to educate consumers and regulators. The CEA Alliance has published the first edition of the Commodity Specific Food Safety Guidelines for Controlled Environment Agriculture Produce Production of Leafy Greens and Herbs, a document that encompasses best practices suitable for the unique needs of the CEA leafy greens and herb industries.13

Sustainability

Several CEA systems use soilless cultivation methods, which can result in significant water savings. However, the major disadvantage is their higher energy requirements, especially for vertical farms, due to their reliance on automated systems including artificial lighting. This can result in increased greenhouse gas emissions if the energy comes from non-renewable sources. Many strategies can be used to reduce energy consumption, such as cladding materials for sunlight diffusion, heat storage systems, and thermal insulating materials.4,5

Indoor farming has the potential to provide several environmental benefits. By reducing tillage, it can help preserve soil health and reduce erosion. These systems can be designed to recirculate nutrients and water, thereby reducing pollution and waste. Due to their small footprint, they can aid in the transition from agricultural soils to natural habitats, helping maintain biodiversity and improving the capacity for carbon sequestration. The lack of economically grown staple crops (rice, wheat, and corn) in a controlled environment is also a major limiting factor in the expansion of CEA to reduce the environmental impacts of food production at a global scale. The high initial investment, requirement for skilled workers, and availability of clean energy are all hurdles to the commercial development of CEA systems.14

Several opportunities for research exist in this interdisciplinary field, such as the impacts that indoor farming can have on food production in regions with water scarcity; the positive effects that a reduction in soil erosion can have on local ecosystems; carbon footprint analysis; and the impacts on carbon sequestration, methane production, and nitrous oxide cycles.9

CEA in the Produce Industry

The increasing interest in produce commodities grown indoors from restaurants and retailers has created the need to establish guidelines by an association such as the CEA Alliance for leafy greens, and for customers and management companies to implement onboarding procedures to verify that CEA suppliers have robust food safety programs.

The following considerations shall be made for approving these types of suppliers: compliance to FDA Food Safety Modernization Act (FSMA) rules; industry-supported third-party certifications; and food safety programs with specific risk analyses that address all water uses and inputs of an enclosed growing operation such as nutrients, growing media, and seeds. Considerations for onsite visits can also be made to increase visibility.

The aforementioned requirements and recommendations shall be used as a baseline for establishing CEA-specific supplier approval programs in preparation for a continuous increase in customer demand. Written sustainability policies and certifications will probably be part of another set of customer requirements in the near future, as forward-thinking companies are already requesting this type of information from their existing suppliers, whether the products are grown in an open or closed environment.

Conclusion

Biological evolution tends to be a slow process, whereas societal change can occur at a faster rate while keeping up with technological advancements. This situation creates a corresponding feedback loop that makes technology evolve in the following way: initially serving a specific purpose, with a subsequent period of blind optimization and a final stage where unintended consequences are taken into account to provide a more comprehensive solution to a problem. This is the case for agriculture, specifically for crop production, which had a slow development for thousands of years, followed by a British agricultural revolution and a green revolution with increasing product yields that are attributable to the application of crop rotation techniques, selective breeding, more complex water delivery systems, and agrochemicals, to the present day where multiple technologies and concepts are being used toward efficient and sustainable production.

CEA provides a credible pathway toward innovation that requires more research and development, widespread acceptance by the consumer, reduction in capital investment, government and industry support, and more interdisciplinary collaboration. The interplay between food safety and sustainability and the recognition of trade-offs is of equal importance to ensure an appropriate introduction of new indoor-grown commodities into the marketplace.

References

- Gómez, C., C. J. Currey, R. W. Dickson, H.-J. Kim, R. Hernández, N. C. Sabeh, R. E. Raudales, R. G. Brumfield, A. Laury-Shaw, A. K. Wilke, R. G. Lopez, and S. E. Burnett. "Controlled Environment Food Production for Urban Agriculture." HortScience 54, no. 9 (2019): 1448–1458. https://doi.org/10.21273/hortsci14073-19.

- Minor, T., G. Astill, S. Raszap Skorbiansky, S. Thornsbury, J. Buzby, C. Hitaj, L. Kantor, F. Kuchler, B. Ellison, A. Mishra, T. Richards, B. Roe, and N. Wilson. "Economic Drivers of Food Loss at the Farm and Pre-Retail Sectors: A Look at the Produce Supply Chain in the United States." U.S. Department of Agriculture Economic Research Service. Economic Information Bulletin 216. January 2020. https://www.ers.usda.gov/webdocs/publications/95779/eib-216.pdf?v=9897.2.

- Neo, D. C., M. M. Ong, Y. Y. Lee, E. J. Teo, Q. Ong, H. Tanoto, J. Xu, K. S. Ong, and V. Suresh. "Shaping and tuning lighting conditions in controlled environment agriculture: A Review." ACS Agricultural Science Technology 2, no. 1 (2022): 3–16. https://doi.org/10.1021/acsagscitech.1c00241.

- Vatistas, C., D. D. Avgoustaki, and T. Bartzanas. "A systematic literature review on controlled-environment agriculture: How vertical farms and greenhouses can influence the sustainability and footprint of urban microclimate with local food production." Atmosphere 13, no. 8 (2022): 1258. https://doi.org/10.3390/atmos13081258.

- Brechner, M. and A. J. Both. "Hydroponic Lettuce Handbook." Cornell CEA Lettuce Handbook. 2013. https://cpb-us-e1.wpmucdn.com/blogs.cornell.edu/dist/8/8824/files/2019/06/Cornell-CEA-Lettuce-Handbook-.pdf.

- Stuchtey, M. and T. Vahle. "Urban agriculture: Boon or bust?" Field Actions Science Reports 20 (2019): 60–67. https://journals.openedition.org/factsreports/5724.

- Shrestha, A. and B. Dunn. "Hydroponics." Oklahoma State University Extension. April 2017. https://extension.okstate.edu/fact-sheets/hydroponics.html.

- University of Arizona College of Agriculture, Life, and Environmental Sciences. "Growing Media." https://ag.arizona.edu/hydroponictomatoes/media.htm.

- Ramin Shamshiri, R., F. Kalantari, K. C. Ting, K. R. Thorp, I. A. Hameed, C. Weltzien, D. Ahmad, and Z. Mojgan Shad. "Advances in greenhouse automation and controlled environment agriculture: A transition to plant factories and urban agriculture." International Journal of Agricultural and Biological Engineering 11, no. 1 (2018): 1–22. https://doi.org/10.25165/j.ijabe.20181101.3210.

- Lensing, C. “Controlled Environment Agriculture: Farming for the Future?” Hort Americas. May 2018. https://hortamericas.com/wp-content/uploads/2018/05/KED-Report-ControlledEnvironment-May2018.pdf.

- Pinnock Brown, L. N. "Integration of Regulatory Compliance Assessments, Microbial Bio-Mapping, and Novel Intervention Technologies for Food Safety Management in Controlled Environment Agriculture: Vertical Hydroponics Leafy Green Facility (thesis)." Texas Tech University. 2022. https://hdl.handle.net/2346/89983.

- U.S. Food and Drug Administration. "Factors Potentially Contributing to the Contamination of Packaged Leafy Greens Implicated in the Outbreak of Salmonella Typhimurium During the Summer of 2021." Current as of January 14, 2022. https://www.fda.gov/food/outbreaks-foodborne-illness/factors-potentially-contributing-contamination-packaged-leafy-greens-implicated-outbreak-salmonella.

- Controlled Environment Agricultural (CEA) Alliance. Commodity Specific Food Safety Guidelines for Controlled Environment Agriculture Produce Production of Leafy Greens and Herbs. October 2023. https://ceaalliance.com/wp-content/uploads/2023/11/cea_guide_oct23-2.pdf.

- Cowan, N., L. Ferrier, B. Spears, J. Drewer, D. Reay, and U. Skiba. "CEA systems: The means to achieve future food security and environmental sustainability?" Frontiers in Sustainable Food Systems 6 (June 2022). https://doi.org/10.3389/fsufs.2022.891256.

- Stein, E. W. "The transformative environmental effects large-scale indoor farming may have on air, water, and soil." Air, Soil and Water Research 14 (2021). https://doi.org/10.1177/1178622121995819.

Javier Martinez, M.Sc. is the Director of Food Safety for Fresh Concepts.