FSPCA Preventive Controls Updated Curriculum Highlights—Advantages for Food Safety Management

The issuance of FDA guidance documents and feedback from FSPCA stakeholders prompted FSPCA to update and issue a new version of its training curriculum

The Preventive Controls for Human Foods regulation (21 CFR Part 117), as mandated by the U.S. Food Safety Modernization Act of 2011, became final in September 2015. This regulation, titled Current Good Manufacturing Practice, Hazard Analysis, and Risk-Based Preventive Controls for Human Food, was enacted to ensure the safe manufacturing/processing, packing, and holding of food products for human consumption in the U.S. The requirements of this regulation apply to businesses in the U.S. or any other country that are required to register with the U.S. Food and Drug Administration (FDA) as food facilities.

FDA recognized that education and training would be needed to help the food industry, especially small businesses, understand the requirements of the Preventive Controls for Human Food regulation once the final regulation was issued. The Food Safety Preventive Controls Alliance (FSPCA) was established at the Illinois Institute of Technology's Institute for Food Safety and Health (IFSH) to meet this need. The FSPCA was funded by FDA, through a cooperative agreement, to initially develop the Preventive Controls for Human Food standardized curriculum1 recognized by FDA. FSPCA has become an internationally recognized, trusted source of training and outreach programs for the food industry worldwide.

Development of FSPCA Training Program

The FSPCA training program serves as the basis for industry training offered by FSPCA trained lead instructors. The regulation requires that certain activities must be completed by a "preventive controls qualified individual" who has "successfully completed training in the development and application of risk-based preventive controls." This is the objective of FSPCA's standardized curriculum, which means the FSPCA participant course is one way to meet the requirements for a preventive controls qualified individual (PCQI). FSPCA not only developed the curriculum, but was also responsible for establishing a cadre of lead instructors worldwide who could provide the training to food safety professionals for these individuals to become PCQIs. To provide evidence of this, FSPCA course participants receive a Course Certificate of Successful Completion issued only by FSPCA.

The initial version of the curriculum was developed and implemented in 2016. Since that time, nearly 2,300 individuals have become lead instructors, and over 148,000 have received FSPCA PCQI certificates. From the time the initial version of the curriculum was released, FDA has developed several guidance documents to assist the industry in developing food safety plans. With the release of these guidance documents, FSPCA recognized the need to update the curriculum based on FDA's current thinking and feedback from FSPCA stakeholders.

While a simple update was possible, this was a good opportunity to reimagine the curriculum with a focus on providing better support to small and midsized food companies, as well as the many international companies that export to the U.S. Finally, there was demand by client companies for the training to be accepted by third-party audit organizations to satisfy their Hazard Analysis and Critical Control Points (HACCP) training requirements.

The objectives for the FSPCA curriculum update included:

- Update data and align with current FDA guidance documents

- Increase small and midsized processor applications by using specific examples

- Streamline sections and reduce redundancy

- Support development of key concepts, examples, and improved chapter layout

- Highlight HACCP principles to gain curriculum acceptance by the Global Food Safety Initiative (GFSI) scheme owners.

FSPCA Curriculum Revision

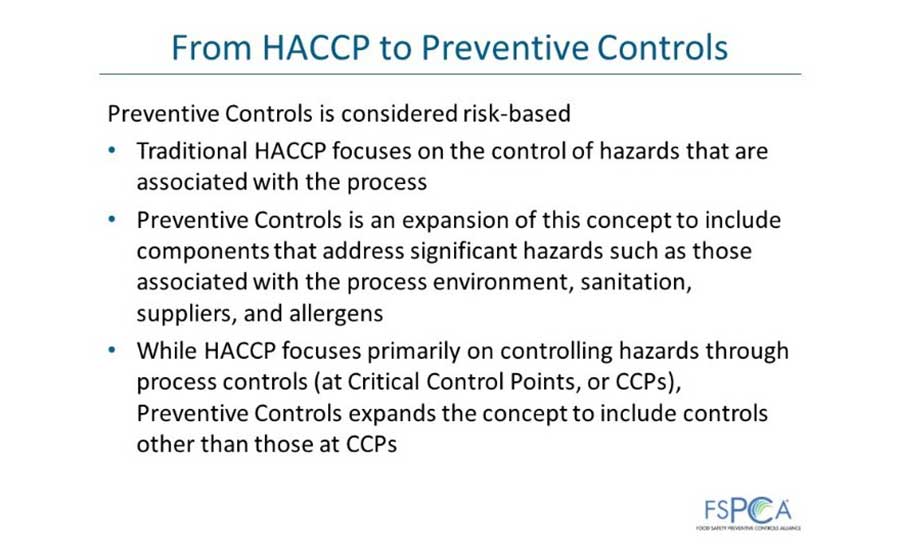

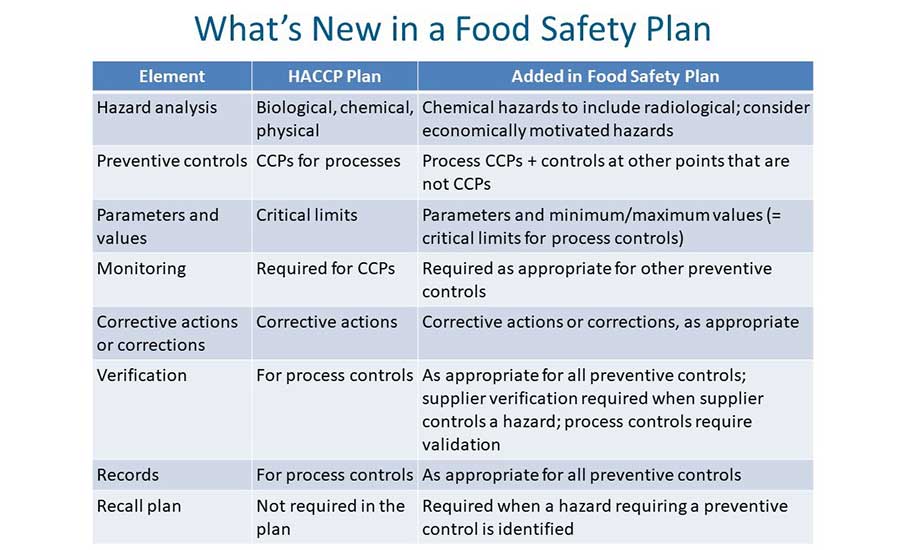

After a nearly two-year effort in updating the FSPCA curriculum, the result is a robust curriculum that aims to provide small and midsized companies with a better understanding of how to develop a food safety plan through better use of examples for implementation and an improved layout that focuses on conveying key concepts. There is now a clear demonstration that the Preventive Controls for Human Food regulation is a HACCP-based system, providing a clear link to the traditional seven principles of HACCP and the 12 steps in the development of a HACCP plan. Building on these HACCP principles through the addition of specific preventive controls beyond process preventive controls, termed Critical Control Points (CCPs) in HACCP terminology, the Preventive Controls approach offers advanced systematic control of significant hazards that have continued to evade traditional HACCP systems, specifically in the areas of sanitation in the post-processing environment, allergen control, and supplier control where the supplier controls a significant hazard (Figure 1).

Updating Data and Aligning with Current FDA Guidance

To keep the curriculum up to date, it was important to ensure that the training material resources and references were updated. Some of the most important and valuable referenced resources in the curriculum are the FDA guidance documents that have continued to be released since the inception of the regulation. While FDA guidance documents will continue to be issued, it is important for participants to be aware that these documents exist and that they can be very useful for developing a food safety plan, especially when conducting a thorough hazard analysis.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

A focus of the curriculum update was to incorporate FDA's Draft Guidance for Industry: Hazard Analysis and Risk-Based Preventive Controls for Human Food. At this point in time, some of the FDA's guidance chapters are not yet complete, and the overall guidance is still in draft form; however, some very informative sections are complete, including "Chapter 3: Potential Hazards Associated with the Manufacturing, Processing, Packing, and Holding of Human Food." This chapter, along with "Appendix 1: Potential Hazards for Foods and Processes," are incredibly helpful in completing the hazard analysis section. In the new version of the FSPCA curriculum, a mini-exercise has been incorporated into the hazard analysis chapter that will provide an opportunity for participants to use these FDA resources. FDA indicated that there will be some likely changes to Appendix 1, so the exercise was designed to take that into account.

Supporting Development of Key Concepts

Throughout the curriculum, more real-world examples were added to help demonstrate implementation of preventive controls. Providing numerous examples in graphical formats will now more clearly convey application of the concepts to course participants—the future PCQIs.

An example of a concept that was more fully addressed is related to decision-making for when a prerequisite program may need to be elevated to a preventive control. In the past, course participants struggled with deciding how certain components of an existing program, such as sanitation, could become a preventive control. This topic is now addressed in the chapter on prerequisite programs and described in more detail in the chapters on allergen and sanitation preventive controls.

More detailed discussion of specific hazards, with examples of controls, is also offered. For example, there is additional explanation regarding chemical hazards including mycotoxins, pesticides, and heavy metals. The chapter on Allergen Preventive Controls provides more specific information on how process steps, such as label receiving and finished product labeling, can be instituted as preventive controls.

At the end of each chapter, a set of knowledge checks has been added to check course participant level of understanding of the key concepts. Instructors are encouraged to use these questions as a point of discussion to gauge participant knowledge and then address any misunderstandings.

Chapter Changes

The changes made to the coverage within the chapters of the current Version 1.2 were substantial enough that the updated version will be designated as Version 2.0. While the Preventive Controls for Human Foods regulation has not changed, the FSPCA Curriculum Team, charged with the update, felt that reordering of some of the training material was needed.

Some of the material within the chapters was streamlined to reduce redundancy. For example, Chapters One and Two in Version 1.2 were combined into one introductory chapter, with some of the course management items moving to the Preface.

The addition of material also necessitated reordering. The introduction of material from the FDA Hazards Guide into the chapter on Hazard Analysis resulted in the current chapter on hazard analysis being split into two chapters. This allowed more time allotted to the important task of hazard analysis and provided an opportunity to introduce a mini-exercise utilizing the Hazards Guide.

The reordering of chapters also paved the way to provide for concept development within the curriculum. Specifically, there was an effort to better link Process Preventive Controls to HACCP through highlighting the seven principles of HACCP.

Linkage of Preventive Controls to HACCP

Preventive Controls is a HACCP-based system, and the FSPCA Curriculum Team felt the need to better demonstrate that. In the current version, Version 1.2, the seven principles were not covered sequentially within the curriculum when covering Process Preventive Controls. Specifically, the topics of verification and record-keeping were covered later, after discussing the other Preventive Controls. In the updated version, all seven principles of HACCP will be covered for the Process Preventive Controls, or CCPs, in three sequential chapters. The in-class exercise for managing the Process Preventive Controls will be completed as is done in HACCP training curriculums, covering all the principles associated with the given Process Preventive Control/CCP.

Chapter 1 includes an expanded discussion on how Preventive Controls were developed from HACCP and why this evolution was needed. A table was added to show the added components of Preventive Controls to HACCP.

For many who teach both HACCP and Preventive Controls, there is a recognition that the added components of Preventive Controls provide advantages over HACCP. While both cover the CCPs/process-related control similarly, Preventive Controls adds CCP-type control to three key areas. In the updated version, an effort was made to more clearly demonstrate this.

One area where there have been far too many recalls is allergens. Most of these recalls occur because of the lack of emphasis on allergen handling and labeling that leads to undeclared allergens. These issues occur when the wrong label is applied to the product, or the wrong product formulation is put into the package. In some cases, the label was improperly designed. By making these facets an Allergen Preventive Control, instead of relying on a single person to monitor the activity, verified monitoring is added—i.e., the labels are checked and then verified by another. The records associated with the labeling activity are verified. By demonstrating how the allergen labeling activity is now envisioned as an Allergen Preventive Control, participants can see the usefulness of applying the Preventive Control concept.

Incorporating Sanitation Preventive Controls will give specific facets of sanitation a CCP-type control. One key area where this comes to support product safety is in the post-processing environment, where exposed ready-to-eat (RTE) product can be contaminated. Many of the Listeria-related recalls that have occurred in RTE products over time have been due to contamination events that occur after processing and before packaging. By having heightened control in the sanitation process, the likelihood of contamination will be greatly reduced. The type of activities as part of a Sanitation Preventive Control can include incorporation of a verification mechanism that cleaning and sanitizing occurred in the prescribed manner; checking of sanitizing concentration; and environmental monitoring of the equipment, floors, walls, and drains.

Supplier Preventive Controls come into play when a supplier is responsible for controlling a significant hazard in a specific raw material/ingredient. In these cases, the receiving facility must incorporate specific verification procedures to ensure that the supplier has indeed controlled the hazard. The curriculum better lays out the specific components for doing this—approving the supplier, determining the verification activities to be used for that supplier, conducting those activities, and then documenting them.

The objective of the FSPCA's Preventive Controls for Human Foods curriculum update is to provide a better educational experience for the course participant. Version 2.0 will be a more dynamic curriculum1 with the updated information, especially the incorporation of FDA's guidance to foster the design of a better food safety plan. The updated curriculum will draw a clear linkage to HACCP while demonstrating its advantages by elevating specific aspects within sanitation, allergen control, and supplier control to the level of control of Process Preventive Controls/CCPs.

Reference

- Food Safety Preventive Controls Alliance (FSPCA). "FSPCA Preventive Controls for Human Food Training Curriculum." 2023. https://www.ifsh.iit.edu/fspca/fspca-preventive-controls-human-food#FPCHF.

Martin Bucknavage, M.B.A., M.S. is the Senior Extension Program Specialist with The Pennsylvania State University's Department of Food Science. He is also a Member of Food Safety Preventive Controls Alliance Executive Advisory Board and Co-Chair of the Curriculum Update Team.

Kathy Gombas is a Food Safety Consultant with FSMA Solutions. She is also Chair of the Food Safety Preventive Controls Alliance Executive Advisory Board and a Member of the Curriculum Update Team.

.webp?t=1721343192)