High-pressure Processing: A Step Toward Sustainability?

Within a five-year European Commission project referred to as “NovelQ” (www.novelq.org), novel processes (NPs) are being developed and evaluated to strengthen the European food industry, with the goal of creating food products with improved quality (freshness). Another aspect of the project is to explore the environmental impact caused by these NPs using life cycle assessment (LCA) techniques.

The work endeavors to compare the environmental impact of products produced by conventional processing with products produced using novel processing, with the overall goal of contributing to the development of environmentally sound food processing. Here, the first of four case studies is presented: a comparison of the environmental impact of tomato salsa produced by conventional heat processing with the impact of a salsa produced by high-pressure processing (HPP).

Environmental Impact of Novel Technologies

The analysis was conducted following established LCA methodology, which is a useful tool for analyzing the environmental impact of a product or service throughout its entire life cycle. The reason why the whole product chain must be considered is that the NP technology might not only have a direct effect on, for example, energy use in industry, but can also affect the resource efficiency (which affects the amount of ingredients needed) and post-processing considerations, such as different storage temperatures and shelf lives (which also affect energy use and wastage).

The study began with defining the system to be evaluated and the purpose of the study. System boundaries were then chosen, stating where the life cycle starts and ends, as well as which activities were included and excluded in the analysis. In this study, four production systems were compared: (1) fresh, untreated salsa (with added citric acid) packaged in a polypropylene tub; (2) heat-treated salsa packaged in a glass jar; (3) high pressure-treated salsa packaged in a polyethylene pouch; and (4) high pressure- and temperature-treated salsa packaged in a polyethylene pouch (sterilized). The resulting products were slightly different in terms of freshness, storage requirements and shelf life (unopened and opened, respectively).

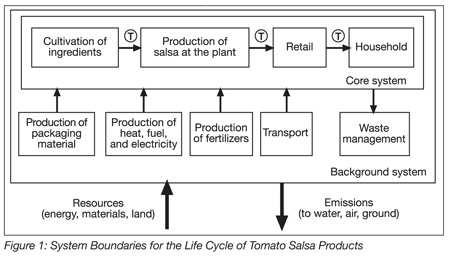

The system that was analyzed in this study started with raw material production in agriculture, including production of inputs, such as fertilizers and fuels. All inputs of packaging materials for the products were included, as was the waste management of the used packaging. Production of electricity and heat, as well as water used in the system, were considered. Electricity for storing in households was also included, as well as all transport involved throughout the chain (Figure 1).

Once the system was defined, the data inventory was collected—that is, data was gathered about the resource use, energy consumption, emissions and products resulting from each activity in the production chain. All in- and out-flows were then calculated on the basis of a unit of the product called the functional unit (here, 1 kg of tomato salsa consumed at the household). Regarding data on production of packaging materials, emissions from transport, fuel production/combustion and electricity generation data from the Ecoinvent Centre (www.ecoinvent.org) were used. For data on cultivation and dicing of onions and tomatoes, as well as the production of tomato puree, previous LCA studies were sourced. Regarding data on production of conventional salsa (input of raw materials, energy use and wastage at the plant), data from an industrial producer in Sweden were used. Data on HPP and packaging were provided by researchers at the Agrotechnology & Food Innovation, part of Wageningen University & Research Centre, The Netherlands, and the University of Naples, also part of the NovelQ project.

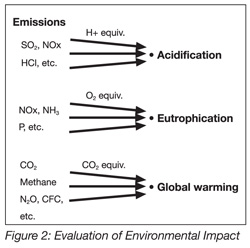

The first result of an LCA is a matrix of inventory results, where the calcu-lated values for each phase of the life cycle as well as the total values are presented for a number of categories of substances, resources from the ground, resources from water, emissions to air, emissions to water and products. To simplify this table and get an idea of what kind of environmental impact the emissions cause, impact assessment methods are used that weigh together all emissions causing global warming potential, acidification, eutrophication, etc. (Figure 2).

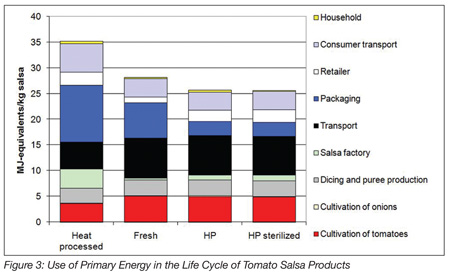

Figure 3 shows the use of primary energy for the different salsa products; the energy use was significantly higher for the conventional salsa product, mainly due to the use of energy for heat treatment at the salsa factory, but also due to the production of glass and metal packaging. The energy use at the salsa factory was quite insignificant for HPP and HPP/sterilization. More energy was needed for retailer storage of the heat-treated and HP-sterilized products; even though the storage was not refrigerated as it was for the fresh and HP-processed salsa products, but because the former are assumed to be stored for 12 months, energy use was still higher for those products.

Transport was quite significant in all four product life cycles (“transport” included all the transport of packaging materials, raw materials and the product up to retailing). Approximately 50% of the energy use for transport was due to the use of lorries (trucks) and the other 50% resulted from barge transport. It is also important to note that the consumer transport accounted for a large part of the overall energy use; the conventional salsa had a slightly higher contribution than the others because its packaging was heavier, and we allocated the burden from consumer transport based on mass.

Contribution to global warming potential is shown in Figure 4; here, it is clear that the fresh salsa had the highest contribution. Slightly more tomatoes are needed to produce the fresh salsa products, resulting in these products having a slightly higher contribution from cultivation compared to the heat-treated product. In terms of packaging, overall, the fresh product with the polypropylene packaging had the highest contribution to global warming potential. We have assumed the plastic packaging would be sent to municipal waste incineration after use, so this would generate carbon dioxide emissions. As the polypropylene packaging was heavier than the pouch used for the two HP products, the polypropylene packaging had a higher contribution. Transport—both goods transport and consumer transport—contributed significantly to this impact category.

Choice of Packaging Is Important

The study results indicate that HP-processed product has environmental benefits compared to conventional, heat-treated product in terms of the decreased energy required for processing. However, the largest difference in environmental impact between the products is not linked to this energy decrease, but rather to the type of packaging that is used and to the composition of the products. The plastic pouch used for the HP salsa products is environmentally preferable, as it is so lightweight.

Furthermore, transport turned out to be a significant factor in terms of the total impact of each product, which is not the case for food products with animal origin that have a much higher impact from the farm stage. As the salsa products are made solely from vegetable raw materials (in our case, vegetables grown in open-air fields) and are sold in fairly small units, the choice of packaging and the logistics of the product are two very important parameters to optimize when aiming to reduce the environmental impact of the product.

In conclusion, the results show that using HP processing is not associated with any additional environmental impact compared with conventional heat treatment, so the freshness of the products can be improved without compromising the environmental profile. However, when developing novel products, the type of packaging is often an important parameter to consider to ensure environmentally sound products.

Acknowledgement

This work has been part-funded by the Commission of the European Communities, Framework 6, Priority 5 ‘Food Quality and Safety’, Integrated Project NovelQ FP6-CT-2006-015710 and by the UK’s Biotechnology & Biological Sciences Research Council.

Jennifer Davis, Ph.D., is a researcher and consultant at SIK—the Swedish Institute for Food and Biotechnology in Gothenburg, Sweden. Her work primarily focuses on life cycle assessment (LCA) of food production, as well as LCA of novel technologies developed within food industry. Recent research interests involve analysis of the climate impact (carbon footprint) of fruits and vegetables.

Graham K. Moates is a research scientist in the Sustainability of the Food Chain Exploitation Platform at the Institute of Food Research (IFR), UK. He joined IFR in 1985 and has worked on a wide variety of projects to help improve our understanding of food ingredients. His research has involved studies into the use of supercritical fluids, plant cell walls, the use of thermoplastic starch as biodegradable packaging, colloids and ultrasonic characterization. He is currently involved in two work packages within the EU-funded NovelQ project concerning life cycle assessment of food production systems and the utilization of food wastes.

Keith W. Waldron heads the “Sustainability of the Food Chain Exploitation Platform” at the Institute of Food Research, Norwich, UK. His research background is in plant cell wall (bio)chemistry with particular reference to food texture and quality. He runs a number of UK- and internationally funded research projects which focus on reducing waste in the agri-food chain. These range from improving the efficiency of processing through to the exploitation of biomass in non-food applications including biofuels. >

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →