Novel Developments in ATP Bioluminescence

Several industrial applications of ATP bioluminescence have been developed since the 1970s. These have largely been non-specific applications used primarily for the direct objective assessment of cleaning verification and as a gross monitor of microbial biomass. Over the past 5 years, significant developments have been made, leading to the first specific test for the detection of low numbers of pathogenic and indicator organisms in 7 hours.

The most widely used application of ATP bioluminescence is for surface hygiene monitoring. This test is very rapid, giving results in seconds and providing a direct objective test for cleaning verification. However, because this type of test looks for ATP, a universal energy molecule that is abundant in most organic materials, the test cannot differentiate between ATP from different sources. Recently, Hygiena has developed a novel reagent technology to make an ATP test that is both specific and sensitive to microorganisms, while reducing the total test time to 7 hours or less. The new test platform is called MicroSnap™.

New Bioluminogenic Assay

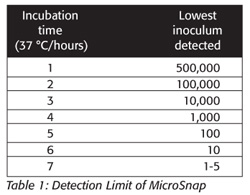

MicroSnap uses a novel reagent formulation where some of the essential cofactors of the standard luciferase reaction are immobilized onto a specific substrate that can only be released in the presence of specific enzymes. Light generation will only occur if the substrate is utilized. The enzyme activity and copy numbers are greater than microbial numbers, thus providing an early amplified signal such that one organism can be detected in 7 hours or less (Table 1).

The test is dependent only on the specific enzyme-substrate reaction so there is little interference from the sample, which has historically limited the applications of ATP bioluminescence for the detection of microorganisms. This allows for a wide range of products to be tested.

A Quick and Easy-to-Use Test

The MicroSnap system consists of two easy-to-use components:

• Sample collection and an enrichment device

• MicroSnap end detection device

The first two MicroSnap tests that have been launched and are expected to have AOAC-RI approval in the second quarter of this year are for coliforms and E. coli. Tests for Listeria monocytogenes and total viable count are expected to be launched by the end of 2012.

The sample collection and enrichment device is fitted with a swab for testing. Alternatively, a liquid sample (1 ml) can be added directly to the swab tube. The liquid can be a suspension of solid sample prepared in the same way and with the same materials as traditional microbiological methods. After adding or collecting the sample, the device is activated by breaking the patented Snap-Valve™ and squeezing the bulb to mix the sample with the enrichment broth. The whole device is then incubated for up to 7 hours at 37 °C. At the desired time points, an aliquot (0.1 ml) of enrichment culture is transferred to the device. The device is activated by breaking the valve and is incubated for 10 minutes at 37 °C; and then placed in the Hygiena hand-held luminometer. Results are generated in 15 seconds and are displayed in relative light units (RLUs). Pass/fail levels can be set for "go" or "no go" decisions or enumeration can be done.

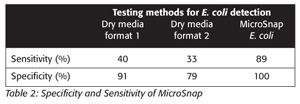

The MicroSnap has been independently verified by a leading food safety and quality laboratory and shown to have a sensitivity of 89 percent and a specificity of 99 percent, which is better than alternative culture method (Table 2).

For low numbers of organisms (1-5), the detection time was confirmed as 7 hours (Table 1) in both pure culture and inoculated foodstuffs, even where the target organism was outnumbered more than 10,000:1 by competing natural microflora. The traditional method detected 95 percent of samples, whereas MicroSnap detected 99 percent of samples. The specification for many industrial applications for coliforms and E .coli is less than10 per gram, which is effectively a presence/absence test for a 1 in 10 dilution of a solid sample (<1 colony per plate). Therefore, MicroSnap gives equivalent results to traditional methods but in a fraction of the time.

Quantitative results for contamination greater than 100 CFU/g are directly related to RLU values and obtained in 4-6 hours. Large volume liquid samples (~100 ml) such as water and beverages can also be tested using MicroSnap.

Modern technology has delivered improvements in reagent performance and instrumentation to produce small, low-cost ATP detection systems with improved sensitivity and repeatability. Further developments of this very rapid and sensitive technology have now made it possible to detect specific bacteria and deliver the same shift test results on the same instruments.

hygiena.net >

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →