Food Safety

The effects of FSMA's sanitary transportation of food rule

Regulation establishes requirements designed to minimize risk during the transportation of food and beverages that could compromise its safety

More visibility in both tracking and tracing from RFID tags helps manufacturers provide cost-efficient and high-quality products to their customers.

Photo courtesy of EU Automation

More visibility in both tracking and tracing from RFID tags helps manufacturers provide cost-efficient and high-quality products to their customers.

Photo courtesy of EU Automation

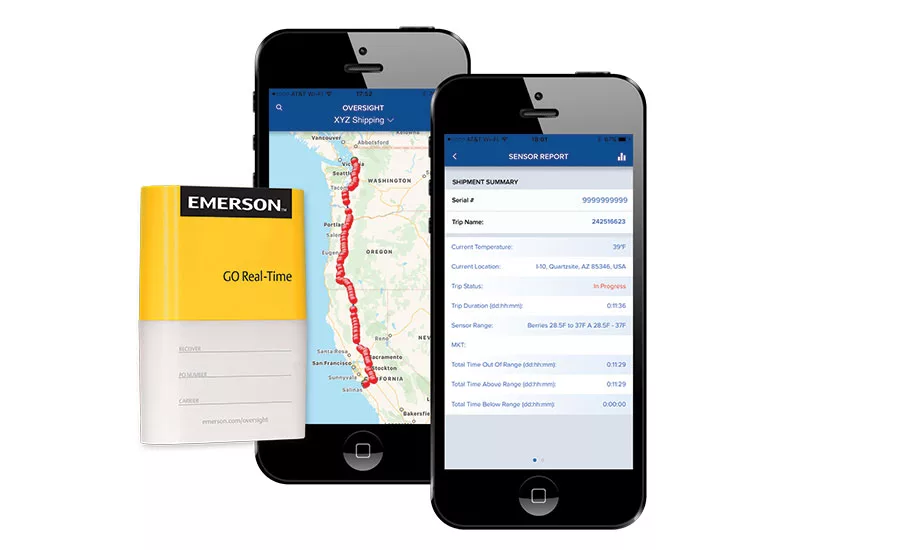

To verify adherence to cold chain protocols, GO Real-Time trackers from Emerson can be placed on a load. The processor can input the serial number of the unit into Emerson’s mobile app and know the temperature and location of the product in real time. Real-time alerts via text and email can also be set up.

Photo courtesy of Emerson

The RTR-601 Food Core temperature data logger from T&D records temperature data that can be automatically sent via wireless communication to a designated email address or an FTP server.

Photo courtesy of CAS DataLoggers

RizePoint’s Mobile Auditor app provides companies tools for performing audits anywhere and also syncs with Bluetooth thermometers and IoT networks.

How GSF uses blockchain technology for food safety

Food distributor Golden State Foods (GSF) has partnered with IBM to explore how IoT can enhance its operations by guaranteeing traceability, specifically in fleet management. Using Watson IoT for Automotive, which incorporates weather, traffic and telematics data, GSF will be able to optimize fleet management—ensuring that food items get to their destination on time and at the right temperature, ensuring freshness and quality.

Guilda Javaheri, CTO for GSF, explains more about blockchain technology and why the company has decided to use it.

FE: Please describe blockchain technology and how it applies to the food processing industry.

Javaheri: When you think of blockchain, think of a shared ledger and an enabling technology for a chain of trusted, traceable and secure transactions. Blockchain technology allows participants in a business ecosystem to record events in a secured network with checks and balances. Blockchain technology provides trusted platforms for data exchanges and collaboration that is inherently transparent.

The adoption of emerging technologies such as blockchain will ultimately enable the food processing industry to completely digitize their supply chain processes. Given the breadth of technologies available, the food processing industry is in a prime position to benefit from improved traceability and real-time data to ensure product integrity and food safety. Since the food supply is global in nature, the need for timely access, collaboration, traceability and trust amongst business partners is more important than ever.

FE: Why did Golden State Foods decide to use this type of technology?

Javaheri: Blockchain technology has the potential to reinvent how supply chains operate and track their transactions. Combining blockchain with Watson IoT information offers the potential to have real-time, immutable, trusted transactions within a business ecosystem that further enhance the quality and trust of supply chain information.

FE: How is IBM’s blockchain technology helping Golden State Foods manage food safety, particularly in its distribution of food products?

Javaheri: In today’s global supply chain of food, it is very important to deliver a trusted product that has all the certifications and validations necessary to guarantee food safety and quality. GSF conducted a Proof of Concept [POC] with IBM to assess the fit and applicability of blockchain technology in the fresh products supply chain. The POC results identified several opportunities for GSF to bring additional value to its business network by leveraging blockchain and IoT technologies.

As a next step, GSF has decided to partner with IBM to leverage IBM’s development and investment in the IBM Food Trust Blockchain platform. GSF is starting a journey to use key elements of the Food Trust platform and develop additional functionality important to restaurants and the supply chains that support restaurants.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

FE: How can this technology help processors comply with FSMA’s STF rule?

Javaheri: Blockchain augmented with Watson IoT information enables the processors to proactively identify any temperature issues and adjust remotely where necessary, preventing the possibility of spoilage. Additionally, blockchain technology provides an immutable timeline of the food’s journey from supplier to restaurant, so that any issues can be spotted instantly and traced back to the source.

FE: How does it automate collecting and analyzing food safety data?

Javaheri: Blockchain enables participants to deploy ‘smart contracts,’ which are business rules encapsulated in code. Smart contracts can automatically perform quality management functions and communicate the result to all appropriate parties in real time. In our pilot, we are also automating capturing temperature data [IoT] and location data [RFID].

FE: What are some of the other benefits to using this technology?

Javaheri: Blockchain together with Watson IoT cuts down significant risks throughout the supply chain. As soon as a product starts its journey, the solution captures the location and temperature of the product from the time that it arrives at a manufacturing facility all the way to its final destination. The instant recording of important data, along with the data’s immutability and security, prevents human error and ensures that anyone can access accurate information at any stage of the journey. It also provides a quick answer to those searching for a product, so if a recall needs to occur, the recall can be pinpointed to specific products in a distinct location—versus recalling an entire product.

FE: Anything else you would like to add?

Javaheri: Blockchain does more than just ‘digitize’ the supply chain. It will ultimately enable GSF and its network partners to use capabilities like ‘smart contracts’ to drive process automation and remove costly reconciliation. A shared, trusted, continuous stream of data about products moving throughout the supply chain enables us to reshape the way we do business within our ecosystem.