FSMA & Lab Accreditation: Tipping Point for Food Safety Testing Labs?

Food safety is constantly in the news, especially in the U.S. Food recalls happen with too much frequency, and when they do, they grab front-page headlines. The underlying concern is that the food we eat each day isn’t as safe as it could be. Given this fear, food production, foodservice and food retail companies and government regulators have increased efforts to ensure food safety, which translates into increased food safety testing.

In fact, the global market for food safety testing has grown roughly 5-10% annually, with growth in some geographic regions and testing areas (North America and pathogen testing, for example) at even higher rates. Strategic Consulting (SCI) has documented this growth in food safety testing over the last 15 years in 18 market research reports.

Food Safety Test Analysis in Food Plant Labs

Until about 30 years ago, food safety testing was conducted in laboratories based at the food processing plant. Food samples collected from raw materials, the production environment or final products were taken to the food plant lab (FPL) to be analyzed. SCI research estimates that there are approximately 40,000 food plants worldwide with 25 or greater employees and, at one point, all of them had FPLs.

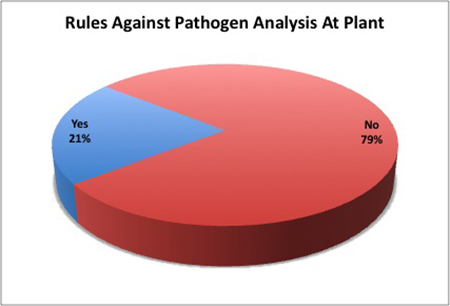

Today’s food safety tests and analysis are more complex. Test instruments are more expensive, operator training needs have increased, and documentation requirements are more extensive and involved. In addition, some food companies have restricted the types of tests (e.g. pathogen tests) that can be analyzed in the plant, further impacting the value of in-plant labs. All in all, running a FPL and generating quality data has gotten tougher.

Today’s food safety tests and analysis are more complex. Test instruments are more expensive, operator training needs have increased, and documentation requirements are more extensive and involved. In addition, some food companies have restricted the types of tests (e.g. pathogen tests) that can be analyzed in the plant, further impacting the value of in-plant labs. All in all, running a FPL and generating quality data has gotten tougher.

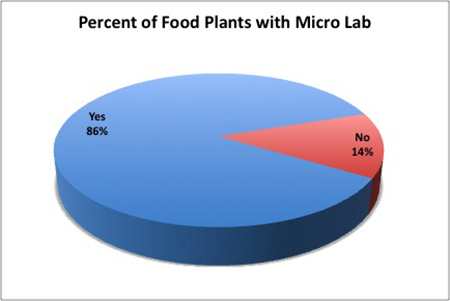

As a result, food plants are debating whether to conduct food safety test analysis themselves, or to send the analysis outside to corporate labs or independent food contract labs (FCLs). As of 2013, SCI research found that just 86% of food plants still run FPLs.

As a result, food plants are debating whether to conduct food safety test analysis themselves, or to send the analysis outside to corporate labs or independent food contract labs (FCLs). As of 2013, SCI research found that just 86% of food plants still run FPLs.

In response to the public’s growing concerns about food safety, there have been a number of regulatory and food industry initiatives in recent years. In the U.S., the Food Safety Modernization Act (FSMA) was signed into law in 2011 and implementation is ongoing. Industry alliances like the Global Food Safety Initiative (GFSI) and the Food Laboratory Alliance also have emerged. A common goal of many of these initiatives to regain consumer confidence is the accreditation of food safety testing labs, to ensure that accurate and consistent data is being used to assess food plant safety.

Accreditation of Food Safety Testing Laboratories

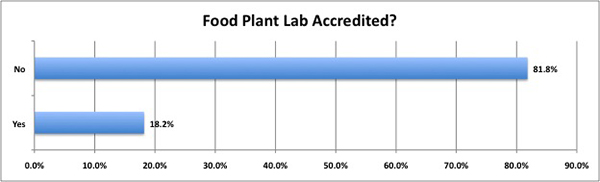

Currently, most FPLs are not accredited. Recent SCI research found that just 18% of QA/QC managers said their food plant labs were accredited, and other sources have reported this percentage even lower.

Lab accreditation is not trivial, and brings added responsibilities and costs. A sizable initial investment is usually required in order to put systems in place and provide proper training for staff. The review fee for accreditation can run $15,000 or more and, once accredited, labs can expect additional ongoing costs for staffing, management and overall compliance.

Lab accreditation is not trivial, and brings added responsibilities and costs. A sizable initial investment is usually required in order to put systems in place and provide proper training for staff. The review fee for accreditation can run $15,000 or more and, once accredited, labs can expect additional ongoing costs for staffing, management and overall compliance.

Merriam-Webster defines the “tipping point” as the critical point in a situation, process or system beyond which a significant and often unstoppable effect or change takes place. Will the drive for lab accreditation be the tipping point for food plant labs, the point at which the bulk of analysis of food samples moves outside the plant to corporate labs or contract testing labs? We think so.

In our conversations with food plant quality assurance/quality control managers and executives, we hear more and more questioning whether running a food plant lab is part of the plant’s core competencies. Are they truly adding value by having a FPL or are they just adding costs and complexities?

Food plants can get fast, quality test results from corporate labs or from increasingly sophisticated (and competitive) food contract testing laboratories. Some FCL companies are even willing to locate food safety testing services in a trailer right at the food plant, or to come in and operate the food plant’s lab outright. Additionally, more and more food company customers, including global food retail and food service companies, are requesting analytical results provided by an accredited third-party lab rather than the food plant itself.

Data from our new report, Food Contract Lab Report (FCLR), indicate that things have tipped, and that the food contract lab market is growing faster than the food safety testing market on the whole. Clearly FCLs are taking market share.

Tom Weschler is president and founder of Strategic Consulting, Inc. www.strategic-consult.com. Over his 30-year career in international management in the industrial marketplace, Mr. Weschler has created, implemented, and redirected numerous businesses, with demonstrable successes in venture capital backed start-ups, publicly traded companies, transformation of underachieving companies, and technology acquisitions. He can be reached at 802.457.9933 or weschler@strategic-consult.com.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →