Articles by Bob Ogren

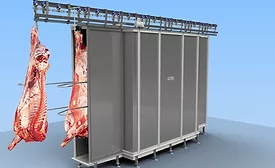

How to use less water for beef processing without compromising food safety

While keeping busy is a good thing, high levels of production require additional use of resources including antimicrobials, water and overall energy.

July 13, 2018

Automation

3 ways sanitation automation helps food processors with food safety

The right solutions can fill labor market gaps while improving safety and efficiency

March 11, 2018

Never miss the latest news and trends driving the food safety industry

Newsletters | Website | eMagazine

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing