2020 Sanitation trend: Conserving resources

In order to properly sanitize equipment, food processors use large amounts of water, chemicals and energy to help meet industry regulations. In fact, food processing plants can use up to hundreds of thousands of gallons of water per day. But, is more being used than needed? In 2020, many processors are looking for ways to conserve, reduce waste, and use data to better understand their sanitation process. Fortunately, the solution can be found in emerging technology, which allows processors to do more with less.

Better results while conserving resources

Conserving resources is essential in 2020. By looking at processes and understanding where waste occurs and labor shortages exist, food processors can use emerging technologies to become more efficient and even more effective in their sanitation process.

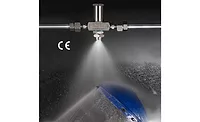

For instance, beef processors can use head and tongue wash precision application technology that allows almost 100 percent of the solution to hit the target. This accuracy can reduce water usage up to 50 percent based on an average of sixty to seventy gallons per minute at fourteen gallons per head. Relying on this new technology reduces waste, minimizes contamination and provides data that processors can use to meet sustainability goals.

Experts have also found ways to harness electrostatic technology, which works by applying an electrical charge to antimicrobial solution. When used properly, this new technology can reduce water and chemical usage by as much as 95% in comparison to dip tanks and other conventional methods. This technology also provides log reductions in the range of 2.0 to 2.6 or better.

Furthermore, using less water means less energy is used to heat the water. And because wastewater needs to be treated with chemicals before disposing, using less water also means using less chemicals. Conserving these resources has a direct impact on a food processor’s business and the planet.

Maximizing workforce efficiency

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

Due to a nationwide labor shortage, processors need to be resourceful and automation is an ideal solution. Tasks like cleaning conveyor belts or hard-to-reach areas on equipment can now be automated, giving limited staff more time to dedicate to other tasks. Automated sanitation equipment is also more efficient because it dispenses only the needed amount of chemicals and water and in the proper concentration. By operating with the same quality standards every time it’s used, sanitation automation provides processors reliable consistency in sanitation and resource reduction.

Automated sanitation can help processors get the most out of a tight labor market. By transferring menial and potentially dangerous tasks to automation, sanitation workers can focus on areas of higher productivity.

Data insights for long-term improvement

An additional benefit of automating the sanitation process is the data that the technology provides. Because the technology is tied to various resource usasge, like water, chemicals, and energy, food processors can better manage their processes, inventory, and annual budgets. Having this information helps them justify their investment in new technology as it shows how automation provides a significant cost savings in labor, chemical and water over time.

Start doing more with less

Once implemented, automation allows food processors to do more with fewer resources. It allows them to reduce waste, conserve energy, and create workforce efficiency each day they use it. If 2020 is the year for food processors to conserve resources, automation is the solution.