Automated temperature monitoring to help ensure food safety

In the food and beverage industry, temperature monitoring is an important part of the shipping and receiving process. If the correct temperature isn’t maintained, products may have to be thrown out, thus losing much of a company’s profit in the process.

New technologies

There are many technologies available for monitoring temperature to ensure perishable items are safe, says Jeff Desrosiers, executive vice president, Vitsab, Malmo, Sweden.

“Many transportation vehicles are equipped with wireless temperature monitoring, and they provide real-time temperature monitoring in each equipped vehicle,” he says. “However, these systems can be very costly and not widely adopted.”

Other technologies available are TTRs (Time/Temperature Recorders) or data loggers that record the temperature profile during transport, he mentions.

“They record the temperature profile, in user defined time increments, during the journey of perishable products from start to finish. The recorded data needs to be downloaded and interpreted. These devices are too cost prohibitive to be placed on each package, and the receiver of the perishable items now has the burden to return to data logger. They can also be costly if used on every order,” Desrosiers explains.

Another option, TTIs (Time/temperature Indicators), can provide a visual representation of the transportation journey of perishable products, he says.

“These can be used on each individual package. The receiver of the perishable products knows if there was temperature abuse during transportation, just by looking at the TTI. They are the most cost-effective solution and are thrown away after each use.”

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

Brandon Mayerat, product manager, Graphic Controls, Buffalo, NY, says that as the industry is progressing towards proactive data collection and monitoring, the lowering cost of IoT data loggers is matching consumer demand.

“Complete systematic monitoring that is accessible from the web will allow Safety & Quality Managers to have temperature data at their fingertips while reducing human error. Graphic Controls offers temperature profiles that can be applied prior to or after a shipment,” he says.

A Safety Manager may be more concerned over the Temperature Danger Zone, while the Quality Manager can review at a later date with different parameters, Mayerat explains.

“The temperature logger should be able to stay with the product using automatic updates to lower employee workloads. Today’s loggers seamlessly plug into standard operating procedures by levering IoT connected devices and provide a complete temperature history,” he notes.

Temperature has one of the greatest impacts on food safety, which makes cold chain safety products paramount for perishable and temperature-controlled food and beverage products, says Jeremy Schneider, quality assurance and food safety expert, Controlant, Reykjavik, Iceland.

“Despite the regulatory standards, it is no longer sufficient to only track and trace food products one step up or one step down the food chain. There are new risks being identified with foods at every step of the supply chain, along with a greater capacity to link food with illness, which can directly impact your business' bottom line,” he says.

Traditionally, food brands have struggled with justifying the costs associated with purchasing temperature monitoring data loggers—particularly, single-use loggers and Internet of Things (IoT) sensor technology, notes Schneider.

“However, this is no longer the standard, as there are preventive, scalable, and cost-effective solutions that provide a single source of truth for your end-to-end supply chain,” he says.

There are a variety of ways that temperature monitoring can be conducted to ensure food safety, through actively monitoring and reviewing temperature download information from your carriers, to improved shipping and receiving procedures at your supplier and distributor locations, Schneider explains.

“In the age of IoT, there is a better way. Today, IoT technology can help answer the age-old problem of knowing if the foods during transit will be received in the condition expected,” he remarks. “The ability to see in real-time the exact temperature of the foods within your cold chain provides you with the ability to proactively intervene before a minor deviation becomes a major quality or food safety issue.”

In addition to monitoring products as they move throughout the supply chain, the technology can provide solutions for products while they are stored in facilities and coolers, and deliver full supply chain insights into one cloud-based software platform, Schneider notes. Having access to all of the information allows an organization to implement sustainable improvements throughout the ecosystem.

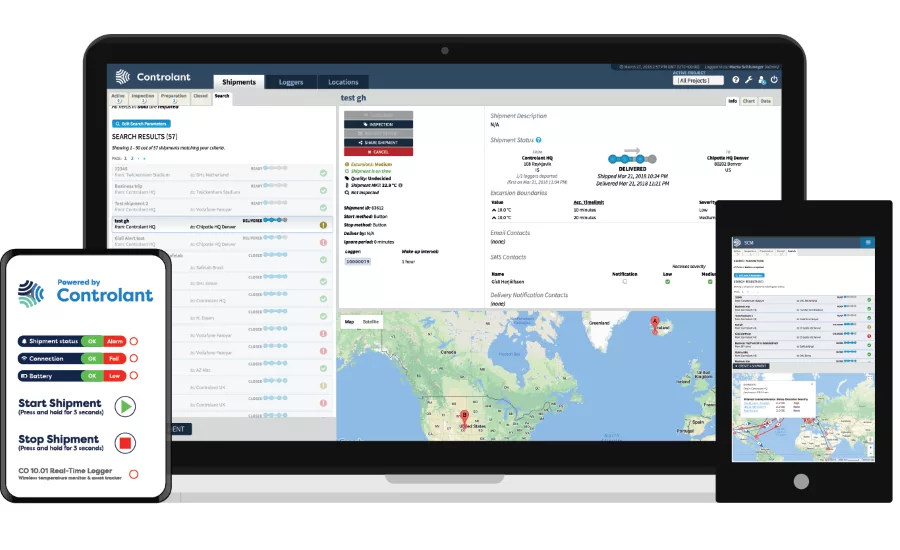

Controlant has developed a real-time temperature monitoring and product movement traceability solution and services that help protect customers from food safety issues and food brands from quality slips that impact customer loyalty and satisfaction, says Schneider.

“The technology allows for access to temperature, location, acceleration and light excursion data in on-demand. Because the system relies on the same cellular network as your cell phone, the equipment is always collecting data and feeding it into the cloud, which is accessible through an app on your mobile device or desktop. To make the system even better, the process works based on exceptions; it will alert anybody who needs the information when a deviation occurs so that corrective action may be taken.”

Schneider says that their solution helps restaurant operators, suppliers, retailers, and other food companies maintain complete visibility and control over temperature-sensitive and perishable products while in transit and in storage.

“The pay-per-shipment Cold Chain as a Service (ChaaS) solution includes access to real-time IoT data loggers which send data to our cloud-enabled software platform, delivering critical analytics and insights, and cost-reducing operational services. Through our partnership, we are helping global brands reduce complexity, increase efficiency, collaboration, and drive a sustainable and intelligent, farm-to-fork supply chain.”

Thus, food brands can:

- Know at all times, in real-time, the temperature and location of products.

- Proactively respond to temperature alerts, product delays, and other quality issues.

- Maintain accurate digital records for compliance.

- Improve supplier and partner relationships.

- No longer rely on third parties for critical supply chain data.

- Mitigate supply chain risk through analytics and insights.

- Drive cost reduction and increased revenues.

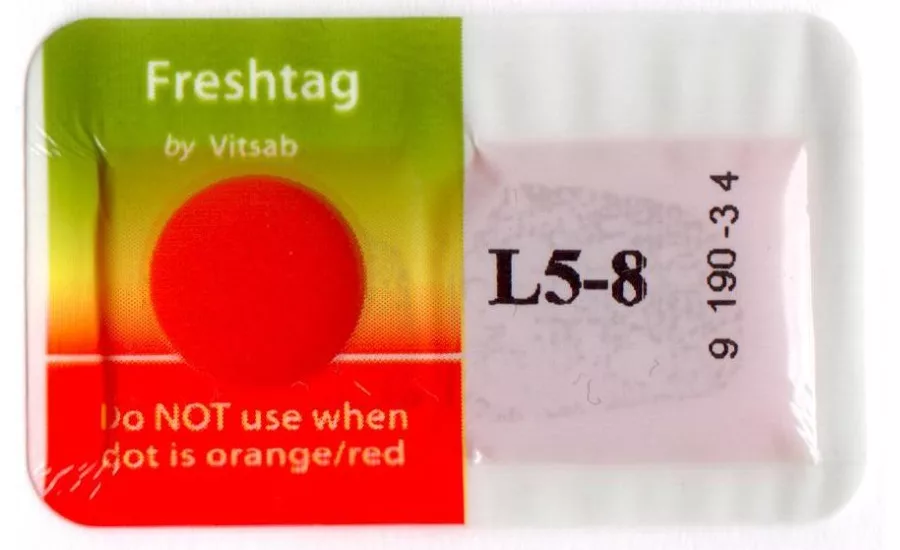

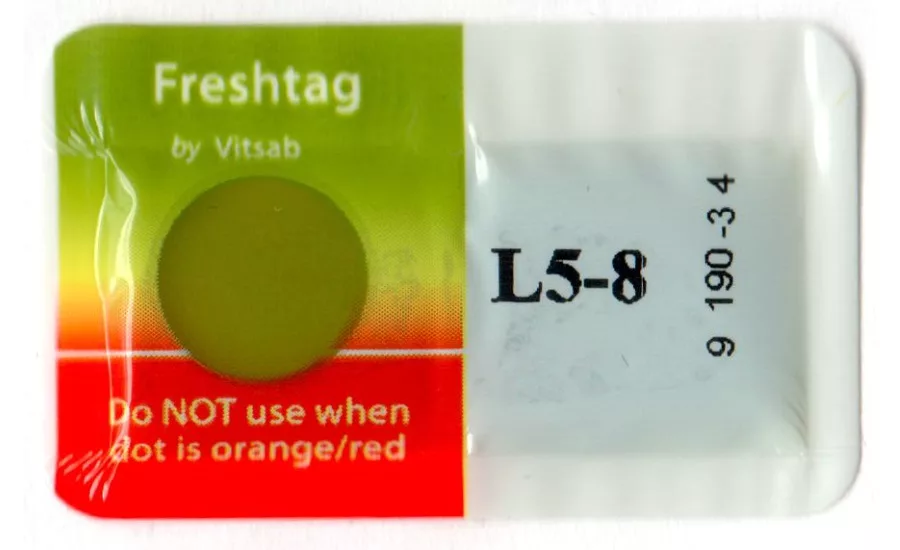

Desrosiers says that their Freshtag™ TTIs use advanced science and are known for accuracy plus temperature monitoring validation.

“They are self-contained and do not need any special equipment for use,” he explains. “Freshtag™ TTIs are calibrated to following regulation requirements for temperature monitoring, so there are no false positives. They will alert the receiver only if there was temperature abuse that will result in low quality and if the perishable products are un-safe.”

He explains that they function like a stoplight, and turn green when activated and remain green for about 75 percent of their useful life. They then turn yellow then red, like a stoplight—therefore, no matter who receives the products globally, everyone understands what a stoplight represents.

“Green means go, the product is fine; yellow means get the product into refrigeration; and red means stop. Recognized globally by regulatory agencies, Freshtag™ are accepted as a cost effective and accurate way to monitor temperature to ensure perishable products are fresh and safe,” Desrosiers adds.

Mayerat says that Graphic Controls offers TrekTag BT and TrekTag Analytics for their customers.

“They have bluetooth technology, which allows for automated reading of tags up to 300 feet away, as well as real-time monitoring with use of cellular gateway or Android device. There are also powerful time and temperature profile settings so you know you’re covered,” he says.

In addition, subscription services allow users to tailor pricing to fit their needs, and there is also facilities monitoring and transportation capabilities with non-hazardous power supply, Mayerat adds.

Best practices

“Our best practices include continuous temperature logging from farm to fork with automated data collection, adding redundancy to the temperature monitoring program without doubling your cost and increasing visibility into the cold-chain, cloud storage that is FSMA and 21 CFR part 11 compliant,” Mayerat notes.

Desrosiers says that Vitsab’s Freshtag™ technology is adjustable, so customers can create new formulations to alert consumers of health concerns.

“For seafood, Freshtag™ L5-8 monitors Fresh Seafood to warn if there is a danger for Clostridium Botulinum Toxin. U.S. FDA regulation requires package level temperature monitoring for fresh seafood packaged in reduced oxygen or modified atmosphere packaging (ROP/MAP) because of health concerns associated with C bot toxin,” he says.

Freshtag™ Shell Safe Shipping monitors Shellstock and are calibrated for vibrio doubling times, a dangerous bacterium found in raw shellfish—for example, oysters on the half shell, continues Desrosiers.

“This product took 3 years to develop and started with U.S. FDA approaching Vitsab to see if our technology was adjustable for additional application. The U.S. FDA provided predictive growth data for vibrio species and Vitsab created a formulation to mirror that bacterium growth. Vitsab then harvested oysters in Connecticut and conducted a summer long study looking at vibrio doubling times and confirmed the accuracy of FDA data plus validated the Freshtag™ Shell Safe Shipping formulation,” Desrosiers comments.

Freshtag™ Catering monitors many perishable items in the same single container, he adds.

“With today’s growing direct to consumer market for perishable items, there is a serious need to monitor temperature in these home deliveries. Vitsab did extensive research on many types of bacteria that could be present in a large variety of perishable items that could be found in these types of packages.”

Vitsab then isolated the fastest growing bacteria and created a formulation to protect against all these bacteria resulting in validation of freshness and consumer safety for these home deliveries, says Desrosiers. A few examples of uses for Freshtag™ Catering are fresh ready-to-eat meals, home deliveries, and airline catering trollies of perishable items.

As with anything in life, “you can't improve what you cannot see,” says Schneider.

“When you begin to see your supply chain in real-time, you are likely to find some fascinating insights, such as temperature deviations and in-transit excursions. Organizations should prepare themselves for these inevitabilities and determine a prepared course of action to manage these incidents,” he explains.

With this said, when implementing a new program such as this, it may be a good time to review contracts, vendor agreements and specifications for your providers to assure that they understand the chain of custody and price of nonconformance, recommends Schneider.

“It is important to assure that the equipment you utilize has been calibrated to exacting detail and has been documented for auditing purposes. It is also very important to assure that you work with partners who can help provide guidance to best practices along the implementation journey,” he adds.

“In the rapidly changing world of technology and the food industry, it is critical to implement state of the art processes and technologies to ensure food safety.”