Sustainable Wet Sanitation to Reduce Equipment Damage

Success can be achieved by working together to reimagine wet sanitation processes that clean effectively and efficiently while preserving assets and improving sustainability outcomes

Maple Leaf Foods is one of the largest Canadian protein companies with 27 manufacturing facilities ranging from fresh pork and fresh poultry to prepared meats and further processed poultry to plant-based protein. As the world's first major carbon-neutral food company, we are motivated to strive for leadership in sustainability practices. Through collaboration with functional stakeholders and external experts, we are excited to share our journey toward a sanitation process that is executed in a more sustainable way. Our sanitation strategy, deeply rooted in performance, was a key enabler to the development of the two core sustainability concepts discussed in this article: asset care and reduced hot water usage. The purpose of this article is to share insights and tips so that all sectors of the food industry that perform wet sanitation can benefit from our experiences in developing a sanitation process that is effective, efficient, maintains assets, and utilizes resources in a more sustainable manner.

Sanitation Strategy Overview

The journey began in 2019 with the approval of a sanitation strategy that defined a performance improvement roadmap to standardize programs and practices across the network of plants performing wet sanitation. Today, Maple Leaf Foods has achieved a more than 80 percent improvement in sanitation performance when compared to baseline, with many plants achieving sanitation performance that is stable and predictable. Knowing what "good looks like" provides a clear reference point to measure the impact of any modifications to the program. This is a very important point, as any change to the sanitation process regarding asset care or improved sustainability must not negatively impact either sanitation effectiveness or the efficiency to perform the sanitation process.

Asset Care

Developing our asset care strategy started with a simple idea—it is time to stop blaming sanitation for the equipment damage caused by water ingress and condensation. Instead, let us start working collaboratively among Maintenance, Operations, and Sanitation to determine the root cause(s) of equipment damage that happens during the sanitation process and implement solutions that are both effective and permanent.

Moving from blame to collaboration was a huge paradigm shift, and it took a partnership between two corporate teams to make it happen. Corporate Asset Reliability and Corporate Sanitation joined forces to take the idea and develop a project plan and program. Several workshops and meetings were required to align all stakeholders and build an action plan with the goal of significantly reducing recurring equipment damage caused by the sanitation process. In the short term, this type of damage is frustrating because it first shows up as downtime during production startup. In the long term, recurring damage results in increased spare equipment components and maintenance budgets that have a component of "planning for failure." Furthermore, constantly completing emergency work orders to fix equipment damage caused by water takes maintenance focus away from the preventive maintenance activities that could help reduce the water damage in the first place.

As an outcome of the cross-functional workshops, an overarching protection standard and a root cause analysis (RCA) procedure were developed for plants to execute when equipment damage occurred and was suspected to be caused by the sanitation process. The implementation of the protection standard started by bringing together a cross-functional team consisting of representatives from Maintenance, Operations, and Sanitation, along with the equipment manufacturer, when available. The team "walked the line" to identify the vulnerable components in the wet sanitation "spray zone," where water is sprayed directly onto equipment surfaces. Once alignment was achieved on what components required protection, further alignment was required for how each component was to be protected and which department would protect it.

Work instructions were developed for every production line by placing pictures on facility schematics to identify all vulnerable equipment components and visually show what the equipment looks like in a protected, ready-to-wash state. The task of protecting vulnerable equipment components was assigned to Operations as part of transitioning the production line from production to sanitation. This was a key process change, since it enabled an additional inspection point where the sanitors were responsible to verify that the production line was securely protected before using the hot water hose.

The second outcome of the workshops was developing a procedure where all equipment damage potentially caused by sanitation would be reported and addressed collaboratively. Plant maintenance and sanitation leaders are required to align on every incident of equipment damage caused by the sanitation process. Repeated incidents or a single, high-cost damage incident were required to go through a root cause analysis (RCA) process to determine why the damage occurred and to develop both short-term and permanent actions to reduce and eliminate future incidents. All equipment damage incidents are reviewed as a standing agenda item during weekly sanitation meetings.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

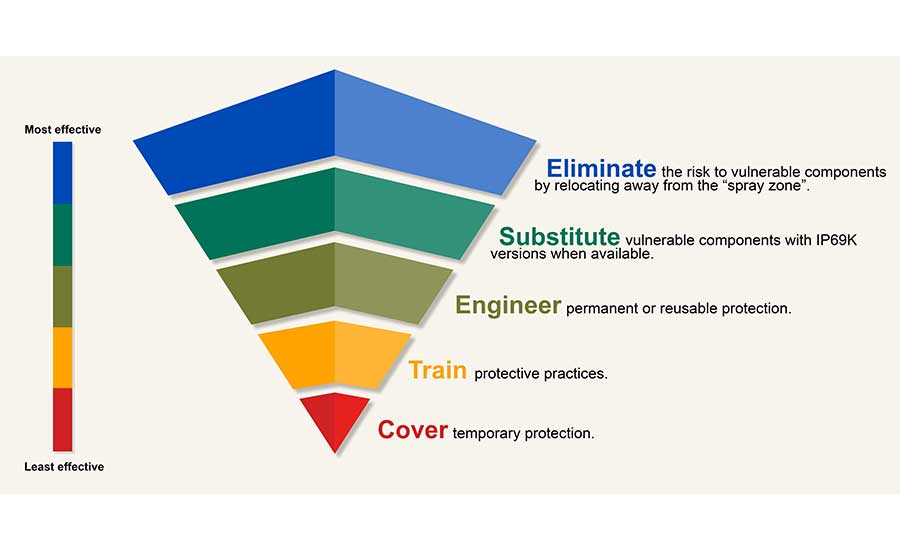

Hierarchy of Controls

Maple Leaf Foods prioritizes preventive measures over reactive ones in managing risks. Another shift in the cross-functional team's thinking was that a plastic covering was not the solution to equipment water damage but, rather, it was the least effective means of control; a starting point that must be considered a temporary measure. Maintenance, Operations, and Sanitation have historically accepted plastic coverings as the only protection solution without considering that "designing out" the water damage risk would be far more effective in the long term. In the protection standard, the team created a graphic called the Hierarchy of Controls (Figure 1) that described the path for higher states of control where employee execution was replaced by eliminating the risk of damage altogether. Starting from the bottom, the "cover and train" levels work together using disposable plastic coverings following the created work instructions; these coverings are not only a physical protection, but also a visual cue to the sanitor that the equipment is vulnerable.

Covering elements can be engineered to further enhance protection by replacing disposable covers with reusable fitted covers or with permanent enclosures. Substitution of a vulnerable component with an IP69K-rated component will provide superior water resiliency, without the need to be covered. IP69K-rated mechanical casing and electrical enclosures are dust tight and able to withstand powerful, high-temperature water jets (wet sanitation process). Although there is premium cost to IP69K-rated components, the total cost of ownership (TCO) is lower over the lifecycle of the asset since the component will not fail as a result of water ingress caused by direct spraying with boosted pressure water. Finally, eliminating the location of the vulnerable component from the "spray zone" entirely is the best permanent solution. Separating equipment electrical cabinets from the equipment and repositioning them to an adjacent wall is a good example. Examples of each control level are shown in Figure 2.

Asset Care System

As early adopters piloted the protection standard and the RCA process, equipment water damage (EWD) results returned early wins. The project team was asked to expand the project scope to include relevant upstream processes. The goal here was to "design in" water resiliency as a factor in the equipment procurement process, and to ensure that the equipment components that were designed to be water resilient were preserved during installation and tested during the commissioning process. The partnership expanded to include Engineering and Purchasing stakeholders and led to the development of a multi-layer asset care program (Figure 3).

In procurement, water resiliency and sanitary design of the equipment drove purchase intent equally to performance specifications and purchase price. IP69K components were stated as a requirement if those components were available. A characteristic selection matrix (CSM) was used to evaluate multiple vendors and to select the winning bid. During installation and commissioning at the plant, a checklist was developed to ensure that the installation of the equipment, including utility connections, preserved the water-resilient design of each installed equipment component. Commissioning trials verified that the equipment was water resilient by being capable of withstanding repeated cycles of daily wet cleaning and non-daily intervention tasks. Additionally, the concept of adaptive sanitation raised the expectation on how a sanitor performs their job. Sanitors must first verify that all vulnerable equipment components are securely protected and also be mindful that protected components are not sprayed directly. The sanitor must control the "force" (pressure and volume) of the water spray to be sufficient to remove soils from the surface, but not excessive to push water and soils beyond equipment seals and gaskets. Water ingress not only results in equipment damage, but also creates a growth niche that could lead to a food safety or product quality risk.

After a year of EWD deployment, stakeholders went back to the plant floor to observe and identify further opportunities for improvement. Taking a Gemba Walk approach led to cross-functional engagement and supported the culture shift. The most significant observation was finding water ingress occurring on many enclosures that were not protected, since they were designed to withstand the wet cleaning process. Once these enclosure doors were opened, seals were found to be broken or missing entirely, and the team realized there was another factor that contributed to EWD. Routine inspection and maintenance to find and address damaged or missing components that provide water resiliency are key parts of the asset care program. The vulnerability of equipment components where the water-resilient design elements (such as seals, gaskets, and glands) were compromised due to normal equipment "wear and tear" or due to incompatibility with sanitation chemistry, pose a greater risk to equipment damage since the sanitor has no idea that unprotected parts of the equipment are vulnerable. Furthermore, loose fittings and damaged conduits also posed a high risk for water ingress leading to damage. Even the rapid change of temperature and humidity when process areas transition from sanitation to operation conditions could cause condensation inside enclosures. If left unchecked without the placement of desiccant bags or heaters, condensation will lead to corrosion that, over time, will result in the failure of electrical or electronic components.

Governance plays a pivotal role to manage program "stickiness" by recording and reporting on frontline metrics so that senior management can provide oversight to support and drive continuous improvement. Driving accountability to conduct cross-functional RCAs for a significant equipment failure prevents complacency and leads to higher levels of control to eliminate equipment damage. Preventive maintenance tasks must include inspection of water-resilient equipment components and immediate remediation to correct any findings. Finally, EWD metrics must be integrated back into the overall maintenance program.

Sustainability

As transportation is moving from petroleum-powered engines to electric- or hybrid-powered systems due to climate change initiatives, is it time to seriously consider ways that the wet sanitation process could be executed in a more sustainable manner? Standardizing sanitation performance and reducing equipment damage due to water ingress set the stage to explore ideas on how to achieve this objective. A plant pilot was started, and everyone agreed to take the "go big or go home" approach to develop a modified wet cleaning process where the equipment itself was not cleaned with any hot water. This was a huge paradigm shift, since the use of boosted hot water defines wet sanitation in so many ways.

From the pilot kickoff meeting on the plant floor, the cross-functional team had immediate engagement and interest to think "outside the box." Operations, Maintenance, and Sanitation representatives "walked the line" to discuss the project scope. When the group got to the cross-cut knife assembly on the primary packaging machine, everyone had something to say. They began working on figuring out a better cleaning process. The first win was agreeing on a new process that avoided using the boosted hot water hose to remove the excess film trim and "confetti" plastic punch holes. Dry cleaning, using a vacuum and forced air, would save up to ten minutes of boosted hot water use from one sanitation hose. This one change could save 30,000 gallons of hot water per year and save 23 gigajoules of energy needed to heat the water to sanitation temperature. That energy would be sufficient to make 23,000 pots of coffee. Now that captured the sanitors' attention!

The team decided to start the pilot on a piece of equipment that ranked in the top three for EWD failures, was lightly soiled, and had a product mix with no allergen concerns. A primary packaging machine was chosen to prove the modified cleaning concept. Wet cleaning a primary packaging machine without the use of hot water posed both challenges and opportunities. If no boosted hot water was used to wet clean the equipment, the team determined that plastic covers to "protect" vulnerable equipment components (such as sensors, online labelers, or control panel screens) were no longer needed. While the side panels of the machine hinged open, the team decided to remove them completely, exposing the entire machine. During the transition from production to sanitation, Operations replaced the task of protecting vulnerable components and instead removed the side panel from the machine. The vulnerability of the equipment with no plastic coverings and no side panels provided a visual cue that the equipment was being prepared to be cleaned in a much different manner, where the use of boosted hot water was not possible (Figure 4).

Now that the equipment was ready to be cleaned, the team developed a modified cleaning process. This exercise required many trials and provided change management challenges. The cross-functional team made a commitment to Sanitation that the efficiency of cleaning would be just as important as the effectiveness of cleaning in the modified procedure. Maintaining the staffing and time requirements was key to get Sanitation fully aligned. The modified cleaning process was not a headcount reduction activity, nor would it create additional stress to complete cleaning within the sanitation window. The final modified cleaning procedure consisted of a sanitizer-detergent application with manual scrubbing, followed by another sanitizer step. Not only was hot water not used on the equipment, the foaming-step was also eliminated. Removable Zone 1 equipment parts such as guards, belts, and framework were cleaned offline, following the current seven-step sanitation process. The Zone 1 equipment was then placed in a clean-out-of-place (COP) tank for additional heat intervention. The surrounding floor and walls were the only surfaces that were cleaned using the boosted hot water hose.

The pilot was initiated on a "live" production line. Without risking food safety and product quality, the first modified cleaning attempts were performed after the last production shift of the week and always followed by the current wet sanitation procedure. Regular metrics such as visual inspection (pre-operation) and swabbing (APC testing) were used to measure the effectiveness of the modified procedure. ATP testing was revised to deploy a "real-time" measure of sanitation effectiveness (avoiding sanitizer interference).

After eight months, the team has completed the first modified cleaning pilot where the primary packaging equipment was cleaned daily without the use of water directly on the equipment. The wet cleaning process has become a non-daily task! Swab data confirmed that the cleaning effectiveness of the modified cleaning process was comparable to the current wet cleaning process using boosted water. The modified process did not change the number of sanitors or the cleaning time. The possible benefits far exceeded our expectations, as not only was hot water use significantly reduced, plastic covering protection on vulnerable parts was also eliminated, and the sanitation chemicals were reduced, as well (Figure 5). The team was successful in proving the concept of developing a wet sanitation process that could be executed more sustainably. Maple Leaf Foods now has a roadmap to follow to expand modified cleaning to other equipment and with different soil profiles.

Hybrid Cleaning

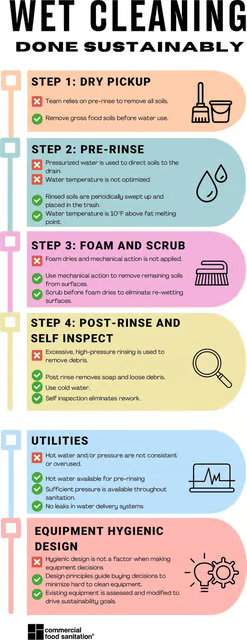

Many plants are not ready to shift from wet cleaning to a non-wet cleaning process and, instead, are looking for execution changes that can be done right now. The hybrid cleaning option considers what typical wet cleaning processes are already doing. The "hybrid" approach can be imagined as wet cleaning with a focus on sustainable goals, where optimized wet cleaning practices are tracked to reduce the amount of water, chemicals, and energy used. The following are real, practical ways to optimize the first four steps of the seven steps of wet cleaning, and how utilities management and equipment hygienic design support the move toward better sustainable outcomes (Figure 6).

Step 1: Dry Pickup. This step provides the first and best opportunity to focus on sustainability goals. The choice between picking up and disposing of gross soils in a dry state with a shovel and bucket versus using the water hose to direct soils to the drain should be clear in terms of sustainability. Ideally, dry pickup is done by Operations as a room transition task from production to sanitation. Sanitation can continue to finish dry pickup before the pre-rinse step. More soils can be removed when equipment guards and small parts are removed and catch pans are moved to knock down soil debris. Sustainable benefits increase with more gross soils removed from the plant in a dry state versus being directed to the drain and collected in a wet state. To build a dry cleaning culture, the expectations of removing all gross soils from equipment and infrastructure must be clearly stated and consistently executed by Operations.

Step 2: Pre-Rinse.The most important factor to water rinse in a sustainable manner is temperature. For equipment surface fat soils, using hot water that is 10 °F above the melting point of the fat soils will remove them through a water emulsion (which is more efficient using less water) versus physically stripping off fat soils using the "force" of the water spray.

The second factor is to manage floor soils. Unlike dry pickup, soils, and water accumulate on the floor during pre-rinse. As in dry pickup, wet pickup during pre-rinse must remove soils using shovels and other tools and not using the water hose as a "floor broom" to direct soils to the drain. Time and water are wasted with continuous spraying of the floor when a shovel and squeegee are more effective. The last factor is to develop a pre-rinse plan to clean efficiently (top-down) and avoid rework rinsing of cleaned surfaces that have been re-contaminated. By coordinating the activities of each sanitor cleaning in the same room, the chance of a cleaned surface becoming re-contaminated by an adjacent sanitor can be reduced. In addition, the entire team must stay on the same step and not rush ahead to the foaming step. The goal of the pre-rinse step must be visually clean equipment and infrastructure with 90–95 percent of food debris removed. Through self-inspection, every sanitor can "earn their foam" and proceed to step three.

Step 3: Foam and Scrub. The most important factor in this step is to focus on not allowing the foam to dry onto the surface before scrubbing. This step is used to remove the remaining 5–10 percent of debris that is difficult to remove with water alone. Using the correct chemical and concentration with scrubbing will ensure efficient removal of all debris. A sequenced approach should be used during this step, foaming from the bottom to the top to ensure good coverage and minimize over- or under-foaming. The mechanical action is also critical to help loosen and remove debris from the surface. One way to achieve the proper sequence and ensure that chemicals do not dry on surfaces is to have a team approach. Assign a person to apply the chemical to infrastructure and equipment surfaces. A second person can start scrubbing treated surfaces using appropriate tools. A third person can then start step four of the process (post-rinsing). Effective teamwork and execution enables post-rinsing to be both effective and efficient.

Step 4: Post-Rinse and Self-Inspect. The most important factor in this step is to focus on rinsing off the foam versus rinsing off soils that were not removed during the pre-rinse step. Excessive rinsing is another form of rework. The post-rinse step is intended to remove the chemical and loosened debris. When cleaning steps two and three are completed as planned, step four can transition to cold water rinsing to gain even further sustainable benefits. Like pre-rinse, this should be a top-down approach and be well-sequenced to minimize re-rinsing. A goal should be that once post-rinse is complete, the water hoses are set aside, and pre-operation deviations are managed through dry means. In summary, when steps one through four are well-executed, the remaining steps will reduce water use.

The hybrid approach includes other factors that support the seven steps of wet cleaning to help achieve overall success in water and energy usage.

Utilities need to support and not hold back sustainability goals. Water temperature and "force" (pressure and volume) are key parameters that must be sufficient and sustained for every sanitor, especially during peak usage when the maximum number of hoses are used during the sanitation window. Water dispensing systems, whether using hoses or spray bars, should be designed, operated, and maintained to be effective and efficient during sanitation. Water volume, pressure, and nozzle configuration must be optimized to support effective wet cleaning with the least amount of water. Spray bars can add further optimization by targeting cleaning at the right location, with the right number of nozzles, oriented with the correct water "force" (volume and pressure). The use of spray bars can also be inefficient if the time for spray bar use has not been determined and controlled by a timer. A "set it and forget it" mindset leads to wasted water, as a longer rinsing time does not lead to more cleaning effectiveness. Finally, the maintenance of water delivery systems is important. Spray bars should be maintained so that all nozzles are clear and are in working order. Hoses and hose connections should be leak-free to stop the slow and consistent water waste.

Equipment hygienic design is a factor that should also be assessed when considering sustainability goals. In addition to IP69K considerations, equipment that is designed with easy access and minimal niches can reduce the amount of water required to rinse surfaces effectively the first time. To help sustainability goals, identify pieces of equipment that need modification or replacement since they are difficult to clean; require frequent re-cleans; or require extensive, non-daily tasks.

Executing the hybrid approach to sustainability does require management and leadership buy-in. Plant leadership needs to support the effort of moving toward more sustainable practices in current wet sanitation. This includes Operations teams helping in daily housekeeping and dry pickup tasks during the transition to sanitation; Maintenance teams "owning" utility system optimization and managing "wear and tear"; Engineering teams that consider design options that are easier to clean; and Sanitation teams with managers and supervisors who train and coach frontline sanitors on wet cleaning more sustainably.

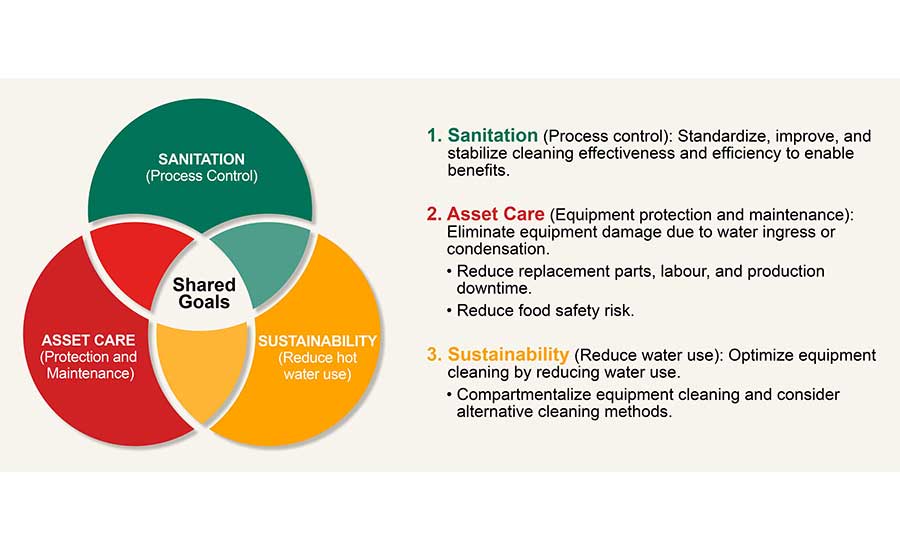

Final Thoughts

Executing sanitation sustainably, when done right, will have a significant impact in so many ways. It is the intersection where stable and predictable sanitation performance enables collaboration and partnerships with key plant and corporate stakeholders to realize shared goals (Figure 7). Success can be achieved by working together to reimagine wet sanitation processes that clean effectively and efficiently while preserving assets and improving sustainability outcomes.

Historically, annual sanitation budgets are reset by reducing the costs of the very resources (i.e., people and chemicals) that sanitation teams need to be effective and efficient. Instead, let us set sanitation budgets that support yearly performance targets to deliver cost savings associated with reducing equipment damage caused by the sanitation process and operating in a more sustainable manner by reducing hot water use. Raising sanitation performance while keeping food safety and product quality at the forefront must be the primary goals. To that end, we must foster a culture where the sanitation process is executed with the participation of all functions and where the sanitation team is both respected and fully supported.

Steven Tsuyuki, B.Sc., B.A.Sc., is the Senior Director of Sanitation for Maple Leaf Foods. Since 2019, he has been responsible for the development and deployment of the company's sanitation strategy.

Cari Rasmussen, M.S., is a Food Safety Manager for Commercial Food Sanitation. She is a consultant and trainer across food industries, focused on sharing best practices related to sanitation execution and hygienic design.

Sumesh Kapoor, M.S., is a Sanitation Manager for Maple Leaf Foods. He has held progressive roles in Operations, Quality Assurance, and Sanitation and supports a network of plants ranging from hatcheries, harvesting, and further processing plants.

Mark McInnes, M.S., is a Sanitation Manager for Maple Leaf Foods. He has extensive academic and work experience in chemistry research and development and supports a network of plants ranging from hatcheries, harvesting, and further processing plants.

.webp?t=1721343192)