Cargill brings facial recognition capability to farmers

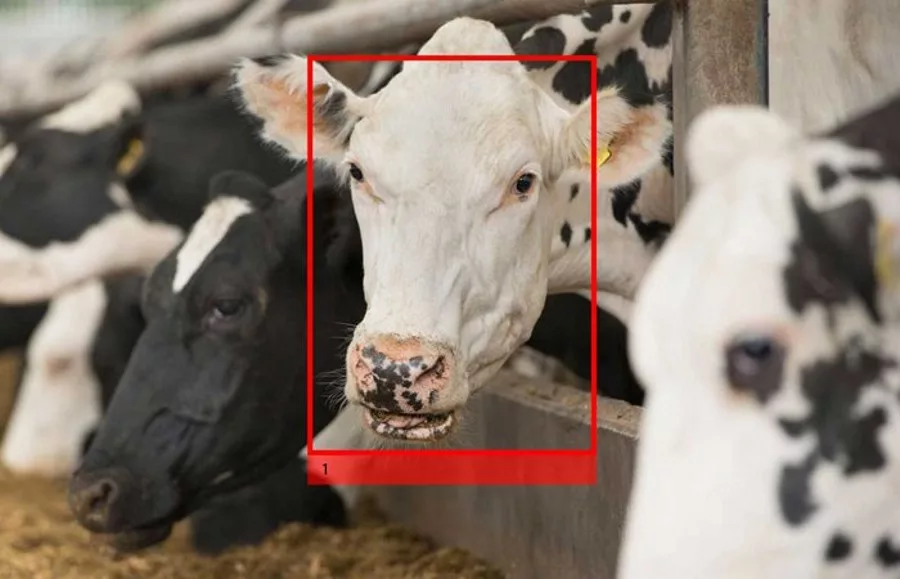

Cainthus uses breakthrough predictive imaging to monitor the health and wellbeing of livestock.

Cargill, Minneapolis, and Cainthus, a Dublin-based machine vision company, are reshaping how animal producers make decisions for their livestock through a strategic partnership that will bring facial recognition technology to dairy farms across the world.

Cainthus uses breakthrough predictive imaging to monitor the health and wellbeing of livestock. Its proprietary software uses images to identify individual animals based on hide patterns and facial recognition, and tracks key data such as food and water intake, heat detection and behavior patterns. The software then delivers analytics that drive on-farm decisions that can impact milk production, reproduction management and overall animal health.

“We are enthused about what this partnership will mean for farmers across the world,” says David Hunt, president and co-founder, Cainthus. “Cargill is a natural partner for us, given their focus on bringing a world-class digital capability to the market and their understanding of how technology will truly help farmers succeed. We think this partnership will be a game changer for farmers because it will allow them to efficiently scale their business.”

Cainthus’ imaging technology can identify individual cows by their features in several seconds to memorize a cow’s unique identity, recording individual pattern and movements. That information is used as part of an artificial intelligence-driven mathematical algorithm that conveys imagery into feed and water intake analysis, behavioral tracking and health alerts that can be sent directly to the farmer. Data gleaned from those images is used to anticipate issues and adjust feeding regimens in real-time.

“Our shared vision is to disrupt and transform how we bring insights and analytics to dairy producers worldwide,” says SriRaj Kantamneni, managing director for Cargill’s digital insights business. “Our customers’ ability to make proactive and predictive decisions to improve their farm’s efficiency, enhance animal health and wellbeing, reduce animal loss and ultimately increase farm profitability are significantly enhanced with this technology.”

Cargill and Cainthus intend to first focus on the global dairy segment, but will expand to other species, including swine, poultry and aqua over the next several months.

“It’s important for us to invest in emerging digital technologies that drive value for our customers and for the industry,” says Scott Ainslie, vice president and group director, Cargill Animal Nutrition. “As an industry leader in this space, we are committed to using technology to address the biggest challenges facing the food system.”

This article was originally posted on www.refrigeratedfrozenfood.com.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →