Global Food Chain Traceability—Reflections on the Past, Present, and Insights into Future Directions

Traceability determines how materials, packaging, products, processing aids, and so forth have moved through the supply chain. Often broken down into two aspects, track and trace, traceability systems underpin food safety, food quality, sustainability claims, and transactional mechanisms to prevent food fraud and food defense incidents.

Tracing is the ability to follow a product backward from the retail shelf to the manufacturer, the ingredient supplier, and their suppliers. Tracking involves following material from suppliers, such as a spice, through to the spice mix and then all the finished products and their destinations where the spice mix was used as an ingredient and/or dusting material. The granularity of traceability is also essential—i.e., the level of detail in which we can determine traceability. Granularity reflects the time element of the traceable unit—e.g., production for one week, one day, one shift, the product produced between the last two quality control checks, and the distance element over which the traceability operates from "one step forward, one step back" (SFSB) through to entire "field to fork" (F2F) traceability. Traceability underpins information sharing in supply chains and characteristics of the data and the systems developed. The characteristics discussed in this article include visibility, transparency, and trust.

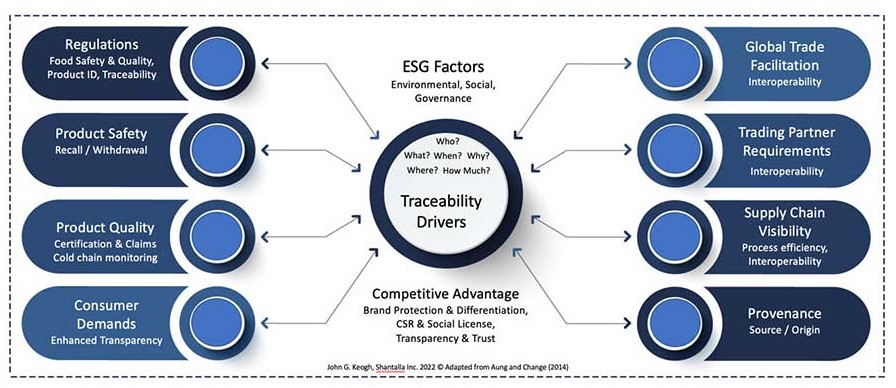

Global Drivers for Traceability

Figure 1 captures the many drivers of traceability in today's global food supply chains. Of note, the GS1 standards organization does incredible work to facilitate product traceability and recall generically and specifically for different food industry segments. For example, the GS1 Traceability Standard1 is an invaluable resource for organizations, and implementation guidance documents are available for beef, fish, poultry, pork, fresh fruit and vegetables, eggs, wine, and more. The traceability standard also details examples of the fast-evolving need for organizations to understand critical tracking events (CTEs) and key data elements (KDEs). For example, the latest U.S. Food and Drug Administration (FDA) Final Food Traceability Rule2 articulates the need for CTEs and KDEs for certain products, with full compliance scheduled for January 20, 2026. The final rule is part of the FDA's New Era of Smarter Food Safety blueprint and implements Section 204(d) of the FDA Food Safety Modernization Act (FSMA).

Food Traceability and Consumer Privacy

Over the past two decades, our understanding of food traceability has grown dramatically. Just like any other emerging field of study or practice, however, it can be shaped and reshaped in different directions until the concept settles and matures. It also differs in how it is applied in practice. Traceability is developing and maturing, but much remains to be tackled. For instance, F2F traceability is frequently discussed and, in some supply chains, has been achieved through analog, paper-based systems. While transitioning to digital traceability approaches has been proposed, there are challenges in collating and open sharing of all information in supply chains (supply chain visibility).

Allergen management is one area where such systems have direct public health implications. A key point not often discussed in F2F traceability is privacy laws, which prevent consumer transactions from being tracked without consent. After all, if organizations or government agencies knew every food item bought and consumed in a household, would people feel this was an invasion of their privacy? Using customer loyalty cards with rewards points in return for providing purchase information is an embedded consumer practice, or purchasing food online and engaging with features such as "your shopping list." However, these data-driven loyalty programs and online algorithms do not give a picture of the totality of food purchases, food waste, and consumption for a given household.

Personally identifiable information (PII) is legally collected when you purchase goods from member-based retailers like Costco, through retailer loyalty programs, or through e-commerce channels. In these opt-in programs, PII is legally captured and may enable the "fork" dimension of proper F2F traceability. If something goes wrong in the supply chain, then these retailers can notify their customers directly of a product recall. If PII is not captured, then only the product identification is known, and the other two "Ps" needed for traceability—the party (consumer name) and premises (consumer's home address)—are unknown and, thus, traceability stops at the retail shelf.

Even if we are aware of and comprehend the goals of F2F traceability, perhaps F2F transparency would be a better framework to approach the topic. We argue that bringing food to market may involve many trading parties and complex supply chains, and business-to-business (B2B) interoperability between these systems is frequently lacking. Apart from short or local supply chains (e.g., a farmer's meat sold at a farmers' market, their farm shop, or vending machines), often called business-to-consumer (B2C) transactions, a customer typically has no access to the information about the many parties engaged in bringing a product to market. Suppose a consumer scans a 2D or 3D barcode on a food item. In that case, they may have limited access to a form of "fork-to-farm" traceback, often accessing only static marketing information about the brand or farm on a website, but receiving little to no data on the route to market (the actual F2F traceability).

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

Of course, a consumer scan is not the same degree of traceback that a food company might perform in a product recall scenario. Still, it can provide a semblance of trust. Providing consumers with static data (e.g., brand details, supplier location, farm location) on the food source lacks granularity. It is an oversimplification of the intricacies involved in end-to-end food chain traceability.

Transparency and Trust

From an organizational perspective, transparency should be seen as a fundamentally important tool for addressing stakeholder and customer mistrust while improving and proving (a process known as nonrepudiation) an organization's responsible management practices.3 In the food industry, we discuss creating a culture of food safety. With his excellent books and briefings, pioneers like Frank Yiannas helped pave the way. Is it now time for executives at large food companies to consider creating and enforcing a culture of transparency? What would that mean for their internal operations, and what does that mean for their shareholders and customers? There is little doubt that the pressures on food companies to deliver safe, affordable, and nutrient-dense foods to market are increasing amid disruptions and conflict.

More specifically for the food industry, product-related transparency was first discussed with consumer safety, environmental politics, and sustainability concerns in mind. Transparency refers to the availability and visibility of data among the parties involved in food supply chains and extending pertinent data to consumers to permit more informed purchasing decisions. Information about the brand owner, the geographic origin or provenance of the raw materials and ingredients, the growing and harvesting practices, the manufacturing processes, working conditions, and environmental effects could be part of specific product information made transparent (visible) for consumers. Providing this information across the supply chain and to consumers can help maintain product identity (preventing fraud and counterfeiting, and thus engaging more governmental and customs support), preserve food quality (verify harvest/best before dates, etc.), food safety (food safety advice, rapid recall notifications of unsafe food), and reduce risk to brand value, among other things.4,5,6

Information on the credentialing procedure for product or process claims, including kosher, halal, and U.S. Department of Agriculture (USDA) organic, to name a few, is conceptualized as a crucial element in transparency data. For example, USDA recently announced7 stricter rules and enforcement actions for USDA organic claims on January 18, 2023, to signal "A significant increase in oversight and enforcement authority to reinforce the trust of consumers, farmers, and those transitioning to organic production." USDA provides a website where a consumer can verify if a particular food company and product are certified to their organic standard. This is a critically important move by USDA, as its organic logo sends a strong signal to consumers and acts as a proxy for trust, especially as it is a governmental scheme with rigorous enforcement.

However, this strong signal of trust is still vulnerable to bad actors that fraudulently claim to have USDA organic certification, but do not. When we checked USDA's website for a list of fraudulent certification claims8 in late January 2023, we found 166 records, consistent with previous years. The highest frequency of fraudulent USDA organic certifications reported was found in the U.S. (31 recorded fraudulent certifications), followed by China (23), South Africa (17), Thailand (14), Mexico (12), and India (9). In Europe, similar instances of fraud with organic products are found—e.g., selling conventionally produced eggs as organic in the UK and Germany, dilution of organic pistachios with the conventionally grown product identified in Spain, and the Italian "Puss-in-Boots" incident with cereals, a highly sophisticated organized crime group network spanning multiple countries and legal jurisdictions.9 With credence-based foods, it is a daunting task to manage a global certification scheme and deliver effective market surveillance. Regulators must encourage an online presence where consumers can verify these product claims.

Supply Chain Visibility

Visibility means that specific data and information are readily accessible for those who wish to use it (both inside and outside the organization) for validation, monitoring, surveillance, and verification of business operations, food product history,10 and to understand both upstream (e.g., suppliers) and downstream (e.g., organizations involved from the business to end user) activities. Supply chain visibility has been described as "traceability and transparency of [the] supply chain process"11 or the "identity, location, and status of entities transiting the supply chain, captured in timely messages about events, along with the planned and actual dates/times for these events."12

Visibility extends beyond traceability's passive, transactional aspects.13 Traceability allows organizations to follow a product or its components forward and backward through a supply chain. Visibility provides information about what happened at each stage—along with the people, processes, equipment, and materials involved—and as a result, the likely food safety impact. For example, in the event of a food product recall for glass contamination, traceability allows an organization to identify the batch size that needs to be recalled, where its ingredients came from, and where the product went and to which customers. Visibility utilizes information beyond traceability documentation to determine what happened at each stage, what preventive measures were or were not in place, and if they had been implemented. The process of visualizing food traceability systems has also been considered in recent research to minimize data loss using material and information flow modeling techniques.14 Still, this aspect of food safety management has yet to take off within business. Information loss can occur at any point in a supply chain where there is a failure or incomplete transfer of traceability data. Minimizing information loss generally drives better supply chain performance, specifically regarding food safety and the potential risk of product recalls.14

Traceability and visibility are only two elements of transparency, as disclosure plays an essential role in delivering transparency.15 Transparency extends beyond the provision of information alone. Transparency provides visibility of how and why decisions were made, what information was used to make those decisions, and who made decisions on behalf of others, e.g., consumers. For example, during a food safety risk assessment, an organization will determine the acceptable level of a food safety hazard that is deemed appropriate (e.g., the limit of detection of the monitoring equipment); however, is this acceptable for a consumer? While a wealth of technologies are now being used in food supply chains to enable digitalization and more real-time sharing of data, if the technologies themselves lack transparency and explainability, this may cause consumers to be concerned about what has been disclosed by an organization and also what has not.15 Trust is built on the foundations of traceability, visibility, and transparency. Roy (2021) summarizes that while traceability maps logistical interrelationships between products and their component parts, supply chain visibility seeks to integrate information sharing across the supply chain to build governance structures and maximize coordination, productivity, and performance.16

The Future Food Supply Chain and the Growing Importance of Sustainability

Sustainability is usually viewed as an attribute of a practice that impacts the use and application of resources in such a way as to allow any foreseeable future generation to be able to employ such resources to meet their needs effectively. To be meaningful, a definition of sustainable practice requires an understanding of the following:

- The social, economic, and environmental resources required for the practice

- The factors that may limit those resources

- The factors that may grow those resources

- Alternatives to those resources.

Because sustainability includes social attributes, it is an important (perhaps the most important) part of ensuring equity in a food supply chain. The farmers, seasonal workers, and distributors involved in sourcing for the food supply chain must be sustained with just as much care as the soil, water sources, and pest remediation necessary to bring the foodstuffs to harvestability. Economic sustainability must include sufficient resiliency so that the workers relevant to food production are not readily enticed to seek other activities and employment when the opportunity arises.

The economic aspects of sustainability require careful consideration of how both net profits and insurance-based protection for safeguarding future net profitability are distributed from the farmer through to consumers. Based on recent work, sustainability can be modeled economically with a combination of persuasion and operant conditioning incentives (ethos and positive reinforcement), with traditional willingness-to-pay/marginal cost (WTP-MC) curves, and with sensitivity analysis-enabling Likert surveys.17 Incentivization and persuasion must adapt to the realities of the food supply chain, as for any other form of sustainability. Based on this, sustainability in the food supply chain is conditional to the current state of knowledge of the resource requirements of this supply chain and the impact the logistics of this chain place on the resources required for the practice. Sustainability is an innately mutable state, and preparing for that fact will aid in designing supply chain processes that are preadapted to change with the exigencies of each supply chain. Two key organizational resilience attributes are agility and buffer capacity.18

The environmental resources associated with a food supply chain are, on the surface, the most obvious aspect of a sustainability plan. However, most plans are relatively superficial, focusing on the suppliers with which the logistics network (procurement, distribution, warehousing, and retail) has direct interactions. Since sustainability must be concerned with factors that may limit or grow the resources required by these suppliers, a resilient sustainability plan must include secondary and even tertiary suppliers to ensure that the primary suppliers have multiple sources for their supplies, including seed and feed, pest remediation, irrigation, transportation, and seasonal access to labor and logistics support. No one can plan a contingency for every potential vulnerability. Still, there is an increased need to add layers to the sustainability plan to provide a faster, more effective response to exploiting strategies for these climate, geopolitical, and pricing vulnerabilities, as well as other crises. Insurance companies are already involved in protection strategies for weather uncertainties and climate change risk mitigation;19 they are undoubtedly to become more involved in sustainability and supply resiliency planning in the future as part of strategies to lower their exposure to risk.

Emerging Technologies

The growing fields of systems engineering and developing circular rather than linear economics combine to provide emerging technologies and practices for more broadly establishing sustainability in food supply chains and providing improved and transparent means of modeling and evaluating them. Sophisticated modeling techniques such as lifecycle analysis (LCA), technical-economic analysis (TEA), and agent-based modeling (ABM) allow sustainability to be modeled on a farm-to-farm level, affording a bottom-up basis for an accurate overall picture of total resource use in a complete supply chain.

Additionally, multiple forms of economic modeling, such as the WTP-MC curves mentioned previously, enable a top-down approach to be simultaneously employed. From the comparison of bottom-up and top-down models, anomalies in the alignment of these two or more modeled networks help identify the locations most likely to deviate from the models. In these locations, extra attention can be paid to refine the models locally and also to adjust the models overall. This type of multi-network anomaly detection can be used for sustainability along adjacent (and equally important) topics of cyber-physical security, IoT, and other sensing, analytics, and identification of potential illicit trade and human trafficking.20

From the perspective of putting a broad program in place, sustainability starts with using what is already available; e.g., asset inertia or "sunk costs." Recognizing, for example, that the manufacturing sector has invested trillions of dollars in existing equipment and processes means that sustainability experts will look at ways to migrate these existing resources to improved resources without incurring higher costs (to the social, economic, and environmental aspects of sustainability cost modeling). Where possible, sustainability can be adopted from the ground up; for example, in creating carbon-negative infrastructure materials.21,22 Also, the approach of trying to employ sustainability in the most difficult of environments (e.g., spaceflight) and then being able to "back off" the solution to the more mundane applications is attracting adherents.23 It is essential for businesses to consider both offsetting strategies and also insetting, making processes and activities more efficient and, as a result, reducing their environmental impact.

The Services Chain

In terms of delivering transparency, the services involved in getting food products to market is an area that we believe is underdeveloped and receives little attention. The research division of the Asia-Pacific Economic Cooperation (APEC) examined Chile's services industries for wine and fresh cherries in 2015.24 It was remarkable to learn that both sectors needed considerable services for a single-ingredient product. In the wine industry, for instance, "a total of 70 services can be identified in this value chain; 33 of which are more directly related to the wine production phase, while 23 relate to the agriculture phase; an additional 14 services are transversal operations that support all stages of the value chain."24

The cherry value chain consisted of 88 different services. Orchard establishment included seven services across research and development for variety development, preparation and planting, and irrigation installation. Cherry production included 20 services (agronomy, pest control, certification, equipment and transportation, labor); packing included 19 services (certification, packaging, labor, information technology); marketing, distribution, and sales included 12 services; and transversal services included 13 services (finance, accounting, legal, human resources, etc.).

How can the sustainability and credence credentials of the service providers be checked and verified? How can we be sure they are licensed, certified, or authorized, and that their personnel are properly trained and competent? How do we know they followed regulations in both the country of production and the countries to which they are exporting, and used the proper treatments and chemicals? We strongly advise businesses to look into the services needed to bring their products to market. It is crucial to be able to rapidly identify all the services that went into bringing an unsafe product to market when a food recall is necessary and a forensic investigation is required. One particular aspect of note is software as a service (SaaS) and robotics as a service (RaaS) with particular focus on cyber security and vulnerability to cyber-attacks, particularly ransomware.

Verifiable Credentials

Verifiable credentials include many possibilities other than blockchain, which is a specific form of a distributed ledger. Distributed ledgers are multi-party means of providing consensus through a distributed, synchronized, shared record of digital data. Sequential digital signing by each sender/receiver pair in a supply chain has been available for decades by providers and standards bodies such as GS1. Credentials can also be readily provided through the use of digital signing (this can be used for any digital record, from code signing to document signing). Public key signatures (PKI), distributed ledgers tied to transaction signatures, encryption within encryption, and chains of nonces are additional sources of verifiable credentials.

Blockchain provides some non-equitable outcomes. For example, mining the next valid chain in a blockchain is innately susceptible to resource (computing power) asymmetry, thus allowing much of the chain sequencing to fall into the hands of those with the most computing power. Blockchain and bitcoin are also estimated to have the equivalent carbon emissions footprint as the country of Sri Lanka, perhaps double that if all cryptocurrencies are included. Given these facts, we recommend in general to keep credentialling both simple and sustainable: use multi-factor authentication (which also helps in forensic analysis of cyberattacks since the attackers leave their footprint on two or more networks simultaneously), and use tried-and-true PKI for authentication access control and non-repudiation tasks in the food supply chain. Certification scheme holders in the food industry who provide credence verification should investigate using the W3C "Verifiable Credentials Data Model v1.1" to facilitate digital verification of credence claims.25

Summary

Pressure to make sure that the world's food ecosystems are resilient, sustainable, and compliant with environmental and human rights laws is growing. Embedding traceability, transparency, and trust in food supply chains is also essential. The new German supply chain due diligence act,26 which went into force on January 1, 2023, is proof of this. The act mandates necessary steps to be taken by companies in Germany with 3,000 or more employees in order to maintain human rights and environmental protection across their entire global supply chains. The act establishes rigorous standards and promotes increased transparency. The actions and behaviors required to get food sown, grown, harvested, processed, and distributed are largely unobservable by the buyers, unless they have a constant local presence or engage in regular unannounced audits; therefore, companies will undoubtedly face significant compliance challenges and increased transaction costs. Audits, however, have their limitations because they only offer proof for a certain moment in time.

There is little doubt that transparency and trust are essential to the success of future food supply ecosystems; however, the delivery of these criteria in practice remains the subject of much debate.

References

- GS1. "GS1 Global Traceability Standard." Version 1.3.0. November 2012. https://www.gs1.org/standards/traceability/traceability/1-3-0.

- U.S. Food and Drug Administration (FDA). "FSMA Final Rule on Requirements for Additional Traceability Records for Certain Foods." https://www.fda.gov/food/food-safety-modernization-act-fsma/fsma-final-rule-requirements-additional-traceability-records-certain-foods.

- Parris, Denise Linda, Jennifer L. Dapko, Richard Wade Arnold, and Danny Arnold. "Exploring Transparency: A New Framework for Responsible Business Management." Management Decision 54, no. 1, (2016): 222–247. https://doi.org/10.1108/MD-07-2015-0279.

- Hofstede, Gert Jan. "Transparency in Netchains." EFITA 2003 Conference. Debrecen, Hungary, July 5–9, 2003.

- Mol, Arthur P. J. "The Future of Transparency: Power, Pitfalls, and Promises." Global Environmental Politics 10, no. 3 (2010).

- Molnár, Adrienn, Katrien Van Lembergen, Xavier Gellynck, Andras Sebok, and Attila Berczeli. "What Can We Learn from Best Practices Regarding Food Chain Transparency?" 2011 International European Forum. Innsbruck-Igls, Austria, February 14–18, 2011. https://ageconsearch.umn.edu/record/122030/?ln=en.

- U.S. Department of Agriculture. "USDA Publishes Strengthening Organic Enforcement Final Rule." January 18, 2023. https://www.usda.gov/media/press-releases/2023/01/18/usda-publishes-strengthening-organic-enforcement-final-rule.

- U.S. Department of Agriculture. "Fraudulent Organic Certificates." https://www.ams.usda.gov/services/enforcement/organic/fraudulent-certificates.

- Manning, L. and A. Kowalska. "Considering fraud vulnerability associated with credence-based products such as organic food." Foods 10, no. 8 (2021): 1879.

- Schoenthaler, R. "Creating real-time supply chain visibility." Electronic Business, 29, no. 8 (2003): 12–12.

- Ying, Kei Tse, Hua Tan Kim. "Managing product quality risk and visibility in multi-layer supply chain." International Journal of Production Economics 139 (2012): 49–57.

- Francis, V. "Supply chain visibility: lost in translation?" Supply Chain Management: An International Journal 13, no. 3 (2008): 180–184. https://doi.org/10.1108/13598540810871226.

- Kowalska, A. and L. Manning. "Food safety governance and guardianship: The role of the private sector in addressing the EU ethylene oxide incident." Foods 11, no. 2 (2022): 204.

- Islam, S., J. M. Cullen, and L. Manning. "Visualising food traceability systems: A novel system architecture for mapping material and information flow." Trends in Food Science and Technology 112 (2021): 708–719.

- Manning, L., S. Brewer, P. J. Craigon, et al. "Artificial intelligence and ethics within the food sector: Developing a common language for technology adoption across the supply chain." Trends in Food Science and Technology 125 (2022): 33–42.

- Roy, V. "Contrasting supply chain traceability and supply chain visibility: Are they interchangeable?" The International Journal of Logistics Management 32, no. 3 (2021): 942–972.

- Ketkale, Harshwardhan and Steven Simske. "Encouraging Reuse in the Corrugated Packaging Industry Using Persuasion and Operant Conditioning." Sustainability 14, no. 11 (2022): 6454.

- Shadbolt, N., F. Olubode-Awosola, and B. Rutsito. "Resilience in dairy farm businesses: To bounce without breaking." Journal of advances in Agriculture 7, no. 3 (2017): 1138–1150.

- Lyubchich, Vyacheslav, Nathaniel K. Newlands, Azar Ghahari, Tahir Mahdi, and Yulia R. Gel. "Insurance risk assessment in the face of climate change: Integrating data science and statistics." Wiley Interdisciplinary Reviews: Computational Statistics 11, no. 4 (2019): e1462.

- Ordiano, González, Jorge Ángel, Lisa Finn, Anthony Winterlich, Gary Moloney, and Steven Simske. "On the analysis of illicit supply networks using variable state resolution-Markov chains." Information Processing and Management of Uncertainty in Knowledge-Based Systems: 18th International Conference (IPMU 2020). Lisbon, Portugal, June 15–19, 2020.

- Boakye, Kwaku, Steve Simske, Dahl Winters, Brandon Eckard, Jeff Hook, Travis Schultz, and John Yarborough. "Improving Kiln Feed Chemistry and Overburden Wasting through Controlled Consistent Quarry Material Mix: A Case Study at Union Bridge Cement Plant." Journal of Cement Based Composites 4 (2021): 5565.

- Winters, Dahl, Kwaku Boakye, and Steven Simske. "Toward carbon-neutral concrete through biochar–cement–calcium carbonate composites: A critical review." Sustainability 14, no. 8 (2022): 4633.

- Iliopoulos, Nikolaos and Miguel Esteban. "Sustainable space exploration and its relevance to the privatization of space ventures." Acta Astronautica 167 (2020): 85–92.

- Asia-Pacific Economic Cooperation. "Services in Global Value Chains: Manufacturing-Related Services." November 2015. https://www.apec.org/publications/2015/11/services-in-global-value-chains-manufacturing-related-services.

- W3C. "Verifiable Credentials Data Model v1.1." March 3, 2022. https://www.w3.org/TR/vc-data-model/.

- Gesley, Jenny. Germany: New Law Obligates Companies to Establish Due Diligence Procedures in Global Supply Chains to Safeguard Human Rights and the Environment. 2021. https://www.loc.gov/item/global-legal-monitor/2021-08-17/germany-new-law-obligates-companies-to-establish-due-diligence-procedures-in-global-supply-chains-to-safeguard-human-rights-and-the-environment/.

Further Reading

- Keogh, J. G. et al. "Chapter 68: Blockchain: An enabler for safe food in global supply networks." In Present Knowledge in Food Safety. 2022. https://doi.org/10.1016/B978-0-12-819470-6.00008-1.

- Keogh, J. G. and C. Unis. "Rethinking Future Food Chains: Systems Thinking and the Cascading Consequences of System Failures." Food Safety Magazine June/July 2020. https://www.food-safety.com/articles/6695-rethinking-future-food-chains-systems-thinking-and-the-cascading-consequences-of-system-failures.

- Keogh, J. G. et al. "Optimizing global food supply chains: The case for blockchain and GSI standards." In Building the Future of Food Safety Technology. 2020. https://www.sciencedirect.com/book/9780128189566/building-the-future-of-food-safety-technology.

John G. Keogh, M.B.A., M.Sc., is a strategist, adviser, and management science researcher with more than 30 years of executive leadership roles as director, vice president, and senior vice president in global supply chain management, information technology, technology consulting, and supply chain standards. Currently, he is Managing Principal at Toronto-based niche advisory and research firm Shantalla Inc. and Professor of Practice at McGill University Center for the Convergence of Health and Economics (MCCHE). His advisory and research focus is on transparency and trust in the food chain, digital transformation, traceability, and recall.

Steve Simske, Ph.D., is Professor of Systems Engineering at the Colorado State University. In his 20+ years in industry, he has directed teams in research on 3D printing, education, life sciences, sensing, authentication, packaging, analytics, imaging and manufacturing. His books, Meta-Algorithmics and Meta-Analytics, address intelligent systems. Dr. Simske is the author of more than 450 publications and more than 200 U.S. patents. He is an IS&T Fellow and the Steering Committee Chair for the ACM DocEng Symposium, which meets annually. He is an IEEE, NAI, IS&T, and CSU FIIE Fellow, and the Steering Committee Chair for the ACM DocEng Symposium.

Louise Manning, Ph.D., is Professor of Sustainable Agri-Food Systems at the Lincoln Institute for Agri-Food Technology at the University of Lincoln. She is passionate about food and farming and how they support communities large and small around the world and help them to thrive. She has had over 100 papers published in peer-reviewed journals, and has written and published many books for a range of audiences. Dr. Manning's research is focused on the critical issues in society, food, and farming including sustainability, resilience, values, integrity, and trust. She works with academics, communities, industry, and policy-makers to develop new thinking to address the challenges of today and the future.