Establishing effective infrastructure maintenance plans for snack and bakery facilities

Creating and maintaining a strong infrastructure maintenance plan helps prevent food safety risks and saves money

Infrastructure maintenance is vital to snack and bakery facility safety. If any plant area is not maintained properly, recalls and other potentially expensive negative consequences are bound to occur. Regular maintenance is crucial, and many types of software and other tools can aid this process.

Maintenance and monitoring

“Sanitation is an integral part of any food and beverage business,” says Jay Wright, vice president of sales, SOMAX, Inc., Alpharetta, GA. “This goes beyond just the equipment used in the production process, and must include the facility and environment where the equipment is located.”

A majority of food production facilities utilize concrete to create the substrate for the floors and perimeter curbs in production areas, explains David Senn, global accounts, food and beverage, The Stonhard Group, Mapleshade, NJ. Although concrete is very durable, it’s also highly porous and can act like a sponge, allowing harborage points for unwanted bacteria.

“It is important when reviewing your building infrastructure and maintenance plans that you consider how you protect the concrete asset and provide a hygienic surface in areas where food is being handled,” says Senn.

Senn remarks that the best types of flooring for bakeries to promote cleanliness and hygiene would include resinous floors, in either epoxy or urethane design. “These systems, also known as seamless or fluid applied flooring, provide a sanitary overlayment that protects your concrete, creates a cleanable surface, adds slip resistance texture and can withstand exposure from heavy washdown and most highly concentrated cleaning chemicals.”

For a building’s exterior, the walls, doors and roofing must be regularly maintained to ensure integrity, energy efficiency, and food safety, says Joseph Bove, PE, vice president of business development, Stellar, Jacksonville, FL. “Walls must be washed to remove mold and buildup. Horizontal and vertical joints should also be inspected and caulked as needed.”

In addition, the hinges, latches and seals on doors should be adjusted to accommodate building and thermal movement. Bottom sweeps and side seals also need to be checked and replaced periodically, Bove says.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

When inspecting roofing, observe the membrane on the edges, field and at drains, remarks Bove. “It’s also important to inspect membrane penetration locations—i.e., pipe stands, ladder locations, piping and equipment—and seal them as necessary. Scupper locations, gutter attachments and connections to downspouts should be maintained to remove any foreign material that may have collected. Finally, it’s important to inspect flashing at high to low wall, parapet locations, etc., and repair as required.”

When dealing with food manufacturing infrastructure, hygienic design, specifically within the processing areas, is essential to the safety of both the food products and plant personnel, says Dan Lundean, regional account representative, Indue Sales & Services, Inc., Hudson, WI. “From the floors to the walls, proper maintenance will increase the longevity and safety of the building. It’s recommended that management establish regular maintenance inspections throughout the facility, at least two to three times per year.”

Building new facilities

When building a new snack or bakery facility, the building’s infrastructure should be designed to help minimize problems related to ongoing maintenance.

“Applying sanitary design principles to your new, renovated building and equipment will save you a significant amount of money over the lifetime of the plant, because the building and equipment can be effectively cleaned in an economic manner,” says Leonard Steed, regional manager, food safety services, Americas, AIB International, Manhattan, KS. “If you don’t have the internal expertise, use an engineering company that is primarily dedicated to building new food plants. Do your research and choose a company with the expertise and track record for building facilities that are compliant with sanitary operations.”

Lundean recommends factoring in life-cycle costs with your initial layout, and weighing the costs to benefits analysis. “Floors, walls and drains often undergo daily abuse in food production facilities. Therefore, it is essential to choose a proper system and coating to withstand abuse from hazards, including forklift/foot traffic, chemical abuse, thermal shock, impact and other physical infliction.”

Also, keep in mind variables that will help with the most-efficient sanitary design concepts with floorings and walls, advises Lundean, such as generating a completely seamless coating from the flooring to the walls, determining sanitation standard operating procedures (SSOPs) and drain type/placement, and what type of floor finish to use.

Bove recommends designing a building envelope to accommodate the baking process, as well as considering the thermal and wet wash environments. “The selection of finishes should be based on the material’s long-term durability, impervious surfaces and maintainability. Insulated metal panel walls and ceilings are typical.” For walls, Stellar typically uses insulated metal panels, because they’re quick to install, cost-efficient and cleanup-friendly.

The material used for ceilings is also important, Bove notes. “The joint where a facility’s walls meet the ceiling is a crucial design element when it comes to food safety. Similar to the joint where a wall meets flooring, the intersection of a ceiling and a wall must be flashed with trim metal to allow for thermal movement in a manner that doesn’t encourage the harborage of bacteria.”

Finally, for flooring, Bove recommends designing a facility with an adequate slope to direct water toward drains and minimize pooling. “Proper coving where the wall and floor meet helps water wick away from that intersection, compared to a 90-degree angle where moisture could collect. It’s also important to properly locate floor drains to facilitate washdown.”

Ongoing best practices

There are several preventative procedures to execute when handling the general maintenance and upkeep of a snack or bakery facility floor, says Lundean. They include repeated cleaning, regular walkthroughs and inspections, and keeping in touch with your flooring provider. “Repeated cleaning is paramount in keeping a floor’s integrity both cosmetically and structurally sound. When cleaning a floor, make sure to reference back to the SDS (safety data system) that your flooring contractor provided you with. That will ensure that you are using chemicals that are safe for both you and your floor.”

Regular walkthroughs and inspections should be done weekly to assess any visible cracks, holes or fractures on the floor’s surface. If damage is neglected, it can have a greater effect on the floor than what’s solely visible, leaving the floor at higher risk of failure, Lundean continues. “Contacting your flooring provider on an annual or biannual basis will help ensure the coatings are up to OSHA standards. Getting an expert look or opinion can aid with spotting non-visible defects, such as moisture beneath the coating and/or substrate.”

Having a well-defined preventative maintenance plan—and sticking to it—is important, says Jim Oko, director of process engineering, Stellar. “This plan should be reviewed and monitored regularly. Be sure to build in flexibility to this plan—it should be adaptable to the environment and future change.”

Maintaining open communication between operations, engineering, maintenance and sanitation team members is also important, as is scheduling regular meetings with these decision-makers. Any changes to equipment or building infrastructure would warrant a special meeting, states Oko. “Special sanitation maintenance instructions should be reviewed and managed to avoid damage to either the facility’s infrastructure or equipment within the facility. Finally, be sure to have written procedures for each level and area under the facility’s sanitation management.”

Software and maintenance tools

Software can help companies manage infrastructure maintenance. SOMAX offers a full-featured, web-based computerized maintenance management system (CMMS) designed to efficiently provide information to those who need it, so they can plan, schedule and collect the results of maintenance and sanitation activities, says Wright. “SOMAX provides a single integrated solution for managing maintenance and sanitation. The collaboration between your maintenance and sanitation departments can help increase productivity by lowering equipment downtime and improving product quality.”

SOMAX recently added new verification and validation functionality for work that has been completed. Completed sanitation jobs are verified on a pass/fail basis. Failed sanitation jobs will create a new sanitation job request that should be assigned and scheduled to correct any items that did not pass on the first sanitation job.

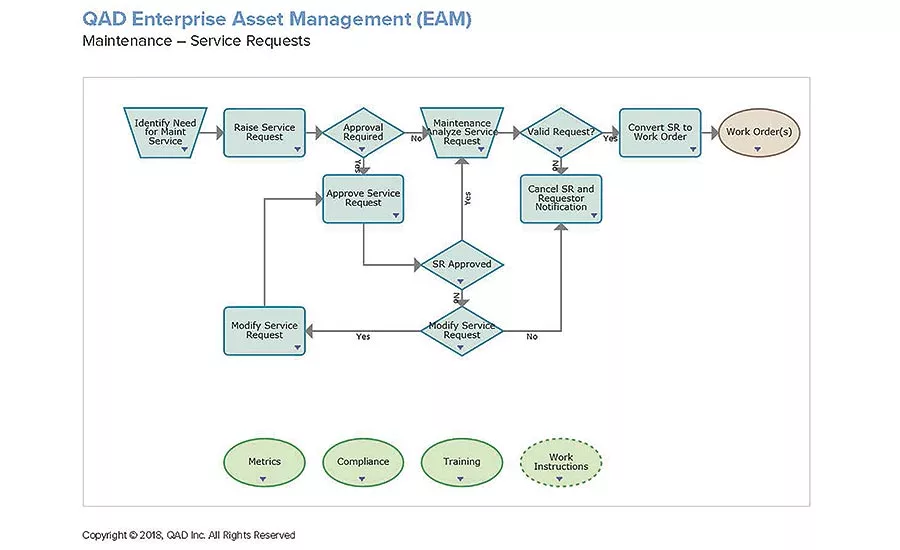

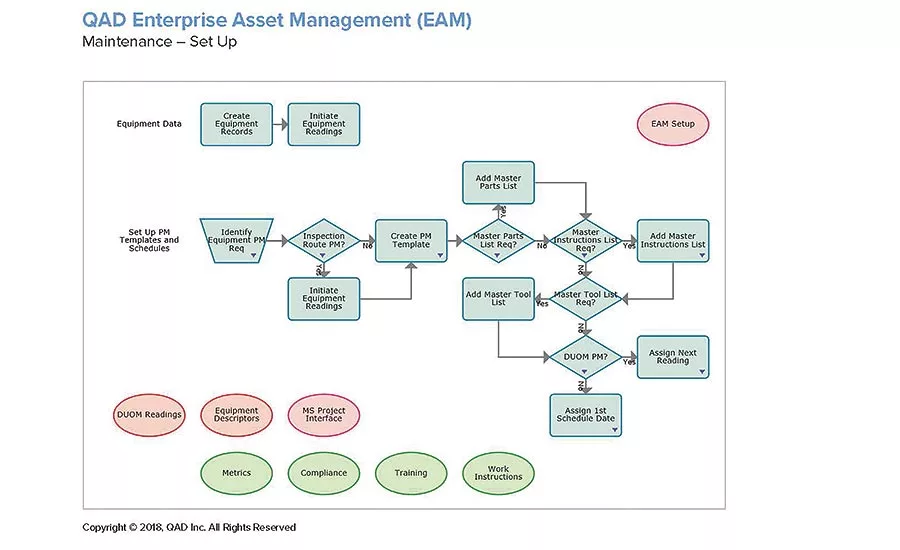

An effective asset management process, along with a sophisticated enterprise asset management (EAM) system, can help manufacturers effectively manage physical assets, says Stephen Dombrowski, senior manager, consumer products, food and beverage, QAD, Santa Barbara, CA. “The entire facility and the mechanical, physical and human components of the operation need to be synchronized, monitored and managed. An asset management process and system that includes design, construction, commissioning, operation, maintenance and replacement of plant, equipment and facilities maximizes and optimizes assets and minimizes repair costs.”

QAD’s EAM system includes capabilities for planned and unplanned plant and tool maintenance, along with other functionalities. “All aspects of facility management and maintenance, from the physical buildings to the machinery inside, are synchronized to ensure a smooth running operation,” says Dombrowski. “In food manufacturing, this is critical to ensure food safety.”

intRAtrain offers clients customized inspection, audit and observation software called inspectiTRAC, says Jerry Van Oort, president, inspectiTRAC by Russell Associates, Le Sueur, MN. inspectiTRAC is designed to help companies of all sizes with the ability to collect and securely store inspection documentation while eliminating redundant work controlling the data.

“inspectiTRAC is comprised of three components: setup, data collection and data management,” Oort explains. “The customizable nature of the software allows it to be used in inspections, audits and observations.”

Data collected via inspectiTRAC can be uploaded to a data management system and/or uploaded to other systems via secure transfer. In addition, inspectiTRAC recently released the mobile version of the tool, which works with all modern browsers, including phones and tablets.

MaintSmart CMMS software uses a unique scheduling system that provides a way to schedule sanitation maintenance for infrastructure, based on multiple criteria, says Daniel Cook, president and CEO, MaintSmart Software, Inc., North Bend, OR. “These criteria include schedule days, areas, functional locations, personnel availability and type of task being scheduled. Additionally, these filters are applied singularly or in any combination as needed by the maintenance scheduler. Once these schedules have been created, they automatically recycle themselves based upon the filters previously applied.”

Each schedule is created in a minute or less, and this and many other tools available in the CMMS software solution can add efficiency to sanitation scheduling, notes Cook.

Software from Nexcor Technologies, Atlanta, such as CAMS-PM for maintenance and KLEANZ for sanitation, are used by companies like Hostess Brands LLC, taking advantage of the integration abilities of the two systems, says Robert Burgh, president.

“Maintenance management and food safety go together with today’s regulations. There can no longer be the ‘me versus them’ mentality between maintenance and sanitation that used to be the status quo. Today’s leading plants must expect and require all departments to seamlessly share pertinent information, both tactically and strategically,” remarks Burgh.

KLEANZ provides corporate and plant-level decision-makers with real-time data from all facilities, and simultaneously supplies maintenance with pertinent information. CAMS-PM and KLEANZ offer regional operations with one or two plants the ability to use sensors to monitor environment and equipment conditions with automatic alerting options.

Other tools, such as moisture meters, instant test kits and infrared thermometers/borescopes, can be used to assist with general floor maintenance and upkeep, says Lundean:

- Moisture meters. Detect the moisture levels within the concrete slab. Can be helpful when floor coatings are damaged or have weakened with age, exposing the substrate and increasing the chance of microbial harborage.

- Instant test kits. Identify bacteria and other harmful pathogens. Common test kits include Listeria, E. coli and Salmonella. Some facilities may require additional testing for alkalinity or acid phosphatase activity found on the floor/walls or products.

- Infrared thermometers/borescopes. Gather readings and/or visuals with flooring or walls.

“With all of these tools available for the sanitation maintenance manager, scheduling takes less effort and is more efficient,” says Cook. “In the end, this saves time and money.”