On Air: Preaching What We Practice

The real achievements in food safety often get lost in the news chatter as we have seen in the very public recalls during the last year. Such commentary frequently feeds the calls for rushed (if not panicked) and simplistic actions that we know will not solve the underlying issues that give rise to food safety problems. From ground beef to spinach we have seen the huge downside of food safety and quality failures. Part of the risk is that the industry now depends on many vendors in extended supply chains. In addition to managing their supply chains, food processors face the challenge of maximizing food safety while reducing costs and improving yields. What examples can we provide of industry success?

One of our missions as food industry professionals is to persuasively present the best practices in food safety and quality management and improvement to the various stakeholders including food safety and quality professionals, the food industry as a whole, the government and the public. From this we should be able to influence the development of industrial and public policy that reflects the best of what we have learned in our work.

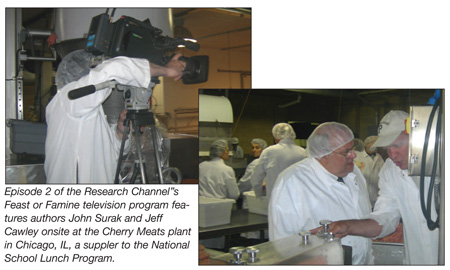

In 2006, Alton Brown presented the keynote address at the Institute of Food Technologists (IFT) Annual Meeting. His charge was that it is our professional responsibility to communicate the serious issues of the food industry to the larger public, including food safety and food quality, so that we can make the right decisions and develop the right policies to provide food to our society. During the summer of 2007, a group of food safety professionals had the opportunity to participate in the production of Episode 2 of the Feast or Famine cable television series, “Food Safety in the Food Supply Chain.” While we cannot say that we reached all of Alton’s benchmarks for communication simplicity (we are afraid we are still at the level of a hammer and have not made it to the rock), the program certainly has given those of us who are stakeholders in food safety the opportunity to move in the right direction.

Will Broadcast for Safe Food

The Feast or Famine television program, which focuses on global food supply and safety issues, airs on the Research Channel and is produced by Capital Media Group (CMG). Historically, Capital Media Group’s focus has been military-related programming, but when CMG president David Holden was hit with food poisoning while on location, he decided to look into foodborne illness.

As Holden tells it, “What drew me to produce this Feast or Famine episode was my personal introduction to contaminated food and foodborne illness. I was traveling for a shoot with the US Army in Texas and the production team and I had a nice dinner the night before the shoot. The next morning instead of filming new communications technology for the military, I was in the emergency room, void of energy from a sleepless night with an IV in my arm rehydrating my body.

“What amazed me more was the fact that this seemed to be acceptable,” says the veteran television producer. “The restaurant was not interested in hearing about a patron who was in the hospital from eating food at its establishment and I was unsure how to report the event to help others from having the same dining experience I had.”

Thus, says Holden, the Feast or Famine series was born. “So I did what I knew best: I produced educational programs on food safety. The first of these was “Food Safety in the Food Supply Chain,” followed by “Mission Critical—Hand Hygiene in Food Service,” and we are working on a new Feast or Famine episode entitled “Imported Food Safety.”

Holden sought out scientific and industry experts to help him explore this topic on film, focusing on those who were involved with the National School Lunch Program (NSLP), which he believed was an ideal case study topic. “When developing the case study for this program I had a few choices, but my research told me those affected most by foodborne illness, with higher death statistics, were young children and older citizens,” he explains. “Again, my personal interest in this story pushed me towards the NSLP. I have a daughter attending preschool soon, and the thought of her eating lunch at school and acquiring the same foodborne illness I had back in Texas, compelled me to learn more about how the U.S. Department of Agriculture’s Agricultural Marketing Service (USDA AMS) and the NSLP were ensuring safe food.”

“I had several questions I wanted to explore,” Holden adds. “What is the USDA doing to protect our school kids? What policies and technologies are being used inside food processing facilities supplying foods to the NSLP? I had to know and I thought others could benefit from this information as well.”

Lights, Camera…SPC Action

Holden approached this article’s authors, for whom the NSLP ground beef purchasing program has been a favorite case, to discuss the creation of a television application profile of the USDA AMS supply chain safety and quality management for ground beef purchased for the National School Lunch Program. We believe that it represents one of most completely developed process management and statistical process control (SPC) based supplier selection and supply chain safety and quality management systems we have seen in the food industry. We told Holden that the specification that details the NSLP program for the current contract year is TRS GB-2007. The document, Technical Requirements Schedule - GB-2007, For USDA Purchases of Ground Beef Items, Frozen—a recommended resource for anyone developing a supply chain safety and quality management system.[1] The document’s author, Steve Olson, a livestock and meat marketing specialist with USDA AMS, developed a state-of-the-art supply chain management system after studying with John Surak the successes of other industries using SPC, and indeed would be an ideal case study to film. Since the first contract in 2003, the AMS program has been consistently successful in increasing safety and improving the quality of ground beef. During this time, the pathogen level has been decreased and the fat level has been centered on the specification target.

Telling this story in the context of a television program was new challenge compared to our normal venue of professional meeting presentations and industry publications. Fortunately, we had the active cooperation of the USDA AMS and of an NSLP ground beef supplier, Cherry Meats of Chicago, IL, which allowed us into their plant to film the process. The AMS administrators who enabled the NSLP program also agreed to appear on screen, including Barry Carpenter, now Executive Director of the National Meat Association; Dr. Kenneth Clayton, Associate Adminstrator, USDA AMS; and Lloyd Day, USDA AMS Adminstrator. Olson, the author of the specification, came to the location, appeared on screen and helped orchestrate the location shoot. Keith and Kerry Pozulp, the principals in Cherry Meats, opened their facility to show how a modern ground beef processing plant can produce product to high standards of food safety and quality by using SPC and process management methods.

The program allows viewers to observe the NSLP purchasing system firsthand and shows how it supports several principles of effective supply chain safety and quality management. Among the take-home messages:

1. Customers need to have the training and knowledge in SPC and continuous improvement. They need to be able to see the ultimate goal, and practice the principles that they are require their suppliers to follow.

2. Customers need to be able to explain the principles of SPC to their suppliers in a way that the supplier can understand. They need to help nurture the implementation program, after the suppliers received professional training.

3. Suppliers must take ownership for their quality/food safety assurance process, and produce product that meets the customer’s requirements.

4. The customer’s senior management must be committed to the process and must have confidence that the process will work. (There were bumps in the implementation of the NSLP process and it took time to refine the process.)

5. Identify potential alternative capacity to provide product so that the customer can take the action to cut suppliers that will not meet the requirements.

6. Develop a partnership with suppliers, and develop a plan so that they can succeed. The suppliers cannot change overnight. There is a lot of work to ensure that they understand the new requirements. These requirements are not implemented in a vacuum. Economic motivators are stronger that the punitive motivators (e.g., being dropped as a supplier).

7. The customer needs to identify key performance indicators that actually measure product performance and supplier’s process performance. These key indicators need to be properly analyzed using SPC.

8. The supplier has the majority of the data. In order to have trust in the data, there also needs to be measures of key product characteristics using an independent measurement system such as a third-party laboratory. The data needs to be compared using the proper statistical techniques.

9. There needs to be an audit system to first prove the supplier has the QA and food safety system properly implemented. The QA plan needs to be a living document rather than something that is placed on the shelf. The customer needs to continually audit the supplier to ensure that the system remains intact. The customer needs constant contact with the supplier, as it is not enough to just look at the SPC data of charts.

10. For continued success, it is necessary to link the SPC program to strong continuous improvement.

That’s a Wrap

The NSLP has been a successful synthesis of what we know about good manufacturing practices. A system based in process management with effective audit procedures can deliver superior results. The important components of success include:

1. A well-thought-out, well-specified and documented process control system.

2. Vendor certification where the vendor demonstrates the capability and capacity to produce to specifications.

3. Implementing this program to begin the vendor/client relationship on the right footing.

4. Continuous monitoring of the product through SPC to demonstrate that the vendor consistently producing the product they agreed to supply.

5. Third-party analysis reporting the same data to both the vendor and the customer, in this case the AMS. This provides a consistent basis for monitoring and for ongoing vendor/customer discussion and negotiation.

6. Established audit procedures to answer if everyone in the supply chain doing what they agreed to do.

7. Well-established criteria for product acceptance and for vendor termination. (For example, When a vendor is found in violation of a contract provision or associated regulation, they can be immediately terminated.)

The application profile in the television program presented Cherry Meats as a great example of the successful vendor, running a tight organization with proper procedures and safeguards in place. We need to develop all vendor/customer relationships that are as successful as the Cherry Meats/NSLP/AMS partnership. The message we to communicate is that, as an industry, we have developed significant capability to provide safe and wholesome to the consumer. As Dr. Gary Lake, University of Wisconsin, Madison, says during the conclusion of the episode, “We can deal with everything related with food safety now. All we need is educating people and having people do what they are educated to do. We have laws in place, we have processes in place, and we don’t need to have any more scientific breakthroughs in order for us to have safe food.”

Jeffery L. Cawley is founder and VP Market Development of Northwest Analytical, Inc., a Portland, OR-based provider of SPC, manufacturing analytics and plant floor quality and HACCP systems. Cawley has focused on the application of analytics and SPC to laboratory and process management systems. He has been active in the AOAC, ASQ Food Drug and Cosmetic Division and the IFT, where is he is a past chair of the Quality Assurance Division. Cawley and John Surak have actively worked for the last decade to establish the role of statistically based process management in successful HACCP systems. He can be reached at jcawley@nwasoft.com.

John G. Surak, Ph.D., is the principal of Surak and Associates and provides consulting for food safety and quality management systems, auditing management systems, designing and implementing process control systems, and implementing Six Sigma and business analytics systems. Surak led the U.S. delegation to ISO committee meetings that developed ISO 22000. Surak can be reached at jgsurak@yahoo.com.

Reference

1. Technical Requirements Schedule - GB-2007, for USDA Purchases of Ground Beef Items, Frozen. www.ams.usda.gov/lscp/beef/lsp-sb-trs-gb-o7 approved_08-13-07.pdf. 2007.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →