The Benefits of Rapid Changeover in a Food Processing Facility

Credit: Andresr/E+ via Getty Images

In lean and process efficiency, rapid changeover is classified as SMED (Single-Minute Exchange of Die). In the food industry, there are many different "changeovers"—e.g., from production to sanitation back to production; from production to maintenance to sanitation; when changing equipment from processing one product to another product; and when moving from one allergen to another allergen. Changeovers can be time-consuming and add considerable waste.

Benefits of quick changeover include:

- Reduced errors and fewer corrective/preventive action events

- Reduced defects, downgrade, and product rework

- Increased production capability and flexibility

- Increased equipment uptime and return on investment—anytime equipment is not making product, the operation is losing efficiency

- Improved communication between departments and teams

- Increased employee morale.

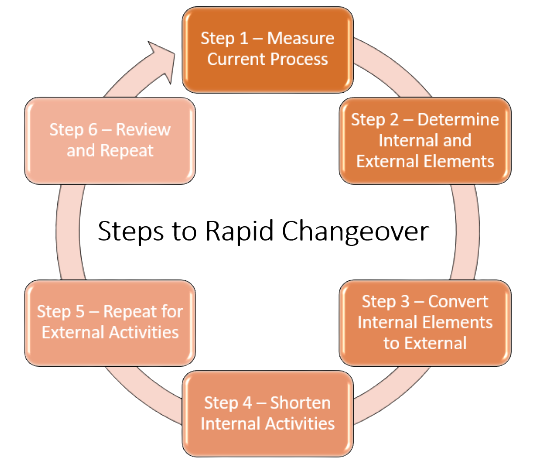

As with everything, there is a process. SMED can be broken down into six steps (Figure 1).

Step 1: Measure Current Process

You will first need to understand the current state. Do this by actively observing the changeover process and then breaking down the process into individual steps. Many facilities find a value stream map (VSM) to be helpful for this purpose. A VSM map details all of the steps, inputs, outputs, and owners of a process in a visual, easy-to-understand graphic. Once the steps are broken down, record the time it takes to complete each step. Measure multiple shifts to see how different people perform the tasks. Observe and measure at least five changeovers to obtain enough data to make a data-based decision. Pay attention to where things are stored, the flow of communication streams, food safety requirements, people safety requirements, etc.

Step 2: Internal and External Steps or Elements

Next, outline what are external operations and internal operations. External steps or elements can be performed, external to equipment, while equipment is still running. Internal steps or elements must be performed while the equipment is shut down. Review the changeover steps and which of the steps/activities must be performed while the equipment is shut down (internal steps). It might be visually easier to color-code the steps. For example, internal is highlighted in the color yellow, and external is designated by the color green. Any color scheme can be used.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

Step 3: More External, Less Internal

Think of preparation and what can be done to support the changeover before the equipment is shut down. Convert as many internal steps as possible to external elements. For example, remove excess packaging and ingredients while equipment is running, gather all the tools and equipment that are needed while the equipment is finishing up the previous run, gather all necessary personnel, wait to return all tools and equipment until after the line is running again, consider what safety checks and permits can be completed while the equipment is running, and other steps.

Step 4: Shorten Internal Activities

Now you have all the internal steps noted on your value stream map. Brainstorm and think about what can be done to shorten the internal steps. Are better tools or equipment available? Can the storage location(s) of the chemicals, parts, and tools be moved so that they are easier and quicker to access? Can the procedure be modified or simplified to reduce equipment downtime?

Step 5: Repeat for External Steps

Next, repeat your brainstorm and think about the external elements. Can you reduce, simplify, or automate any of the external activities? Can you modify or add instrumentation? Can another person perform any of the tasks?

In either Step 4 or 5, think about how you can increase communication—preferably without involving high costs. No one wants to wait around. Quality Assurance will get upset if they are called to perform the after-sanitation checks and pull swabs, and must wait around because the line is not finished yet. However, production also does not want to wait around for Quality Assurance to show up after the equipment is finished. Make an internal communication contract. If you call, the person should be present within a specified number of minutes, barring an emergency. It is important to respect everyone's time and responsibilities.

Although automation and new equipment could be beneficial for the process, simple changes and modifications can also be low cost. Modifications to procedures, or moving steps around to make processes more efficient, do not add much to a company's balance sheet. If new equipment, automation, and/or instrumentation are not affordable at this time, then document the need and add these items to next year's wish list or budget. Record the amount of time saved so that the return on investment is easier to define with management when they make those crucial financial decisions.

Step 6: Review and Repeat

Now, perform a changeover with the new procedure, new equipment, or new process. Re-measure each step to record progress. Remember, continuous improvement is achieved through the Deming Cycle—"plan, do, check, act" (PDCA). Brainstorm, set plans in motion, see how they unfold, update those plans based on results, and then look for similar areas that could benefit. Continue to repeat Steps 3–5 until all logical steps have been taken. Re-measure your new and updated changeover process. Make sure to update and modify standard operating procedures to create the new standard.

The last step is frequently the most difficult—maintaining the gains. Make sure everyone has been trained on the new procedure and has buy-in. If management and staff are not committed to the changes, then the tendency is to fall back on the old way, and soon everyone will go back to doing the tasks the way they did before, which is not necessarily the most efficient way for all departments and job duties.

Summary

Food processing facilities experience many different changeovers. Rapid changeover, or SMED, can be beneficial to increasing efficiencies in a food processing facility. Reduction in downgrade or defects and an increase in employee communication and morale are several benefits of a well-oiled changeover process. I encourage you to get started on a value stream map to help reduce those inefficiencies. Good luck!