Implementation of FSMS and Correlation with Microbiological Criteria, Systems Thinking, and Food Safety Culture

Complex problems can be solved by using systems thinking, along with food safety knowledge and skills

Despite the existence of multiple pillars and tools on which food processors can rely (i.e., food safety legislation, policies, standards, and guidelines related to food safety systems implementation, controls and audits, worker training programs, etc.,1), foodborne illness outbreaks continue to occur, worldwide, at a higher rate. This translates into costly public health emergencies, food product recalls, and a loss of consumer trust in food processors and brands.

Positive Food Safety Culture

Most ongoing and post-outbreak epidemiological reports, as issued by food safety and public health national and international agencies, reveal the high incidence among food processors who fail to learn, adopt, implement, and upkeep a Food Safety Management System (FSMS) along with a strong positive food safety culture within their organizations.2 Failure to implement at-hand food safety tools are the managerial expression of lack of commitment toward the implementation of an FSMS and a positive food safety culture. These will later manifest, in a downstream-cascade fashion, in the processing area and worker behavior, subsequently increasing the risk of foodborne illnesses outbreaks.

Ice Cream Listeriosis Outbreak Cases

An illustrative example of an ice-cream related listeriosis outbreak is the Blue Bell Creameries case. This case was discussed in the authors' previous published case study.3 The authors' findings correlate with reports from the U.S. Centers for Disease Control and Prevention (CDC)4 (Table 1).

Table 1. Violations of HACCP-Based Standard Operating Procedures Identified by Onsite FDA Inspections (Sources: FDA Observation Reports on Blue Bell Creameries Facilities3,5,6,7)

While ice cream might seem to be a "safe" product, especially based on its processing and storage characteristics,8,9 recent incidents of listeriosis outbreaks due to the consumption of Listeria monocytogenes-contaminated ice cream have increased. Generally, the contamination of ice cream with Listeria spp. can take place via the manufacturer's plant environment due to inadequate sanitation procedures,10 during the short storage of the non-frozen ice cream mix under refrigeration conditions, and during transportation to the retailers. A high risk of listeriosis also has been noted when novel ice creams are produced with various ingredients such as: crushed cookie dough or cookie sandwiches and nuts, ingredients that cannot be treated by heat, as a kill step, after the addition to the end product.11

Regardless of the food safety lessons offered by previous ice cream-related listeriosis outbreaks, including the Blue Bell Creameries listeriosis outbreak case of 2010–2015, which was thoroughly discussed and investigated over the subsequent years of 2015–2022, other ice cream listeriosis outbreaks have recently emerged in the U.S. (Table 2). All of the recent cases indicate two main root causes of outbreaks and product recalls:

- Processing environment and workers, which can be address by proper implementation of prerequisite programs (PRPs) such as Good Manufacturing Practices (GMPs), Good Hygiene Practices (GHPs), and Sanitation Standard Operating Procedure (SSOPs)

- The lack of onsite microbial product testing, which indicates a lack of implementing the microbial criteria for the product.

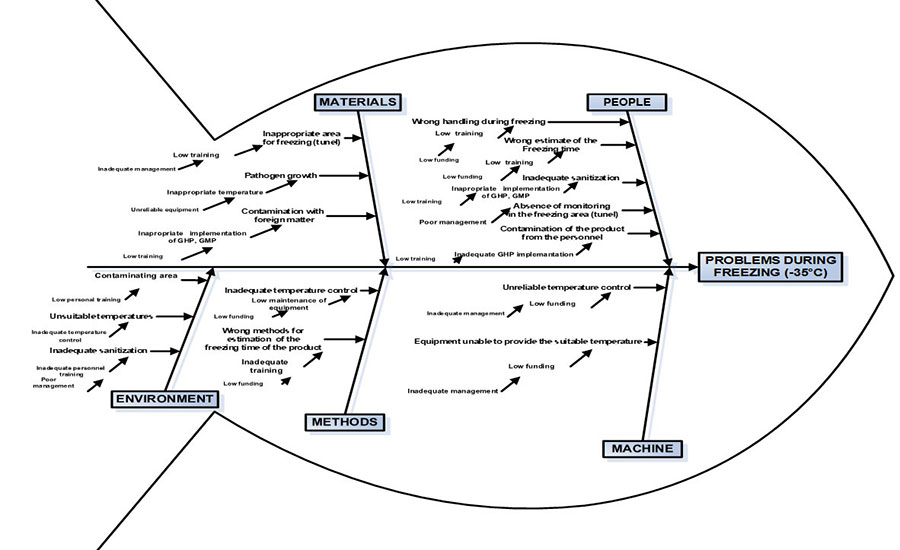

The abovementioned, identified root causes represent a clear indication that the manufacturers did not properly address, prior to or during processing, one important food safety tool—the Fishbone Diagram/Ishikawa Diagram (Figure 1).

TABLE 2. Examples of Ice Cream-Related Listeriosis Outbreaks Recently Emerged in the U.S. (Sources: 2021–2022 CDC and FDA reports)

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

FIGURE 1. Case Study: Fishbone Diagram and Root-Cause Analysis of Blue Bell Creameries' Food Safety Pitfalls that Gave Rise to the Ice Cream Related Listeriosis Outbreak of 2010–2015 (Lee, J.C., et al., 2021)

Food Safety Management Systems and PRPs

Based on the ongoing and historical ice cream listeriosis outbreak data, our study focuses on the importance of Food Safety Management Systems (FSMSs), Critical Control Points and Hazard Analysis (HACCP), and PRPs as the foundation of HACCP, in preventing foodborne outbreaks. Along with the implementation of an FSMS, equally important are other management tools such as the Hazard and Operability Study (HAZOP), Failure Mode and Effects Analysis (FMEA), and Fishbone and Pareto diagrams, which are proactive tools in the maintenance of a positive food safety culture and the prevention of food cross-contamination and food fraud. Leadership plays an essential role for implementing and maintaining a positive food safety culture within food processing plants, and leaders must demonstrate their involvement and commitment.

For example, a negative leadership that nurtures a negative food safety climate induces fear among workers; this is one of the most damaging attitudes for food safety management and food safety culture. Amid this type of "fear culture," workers are usually disparaged from reporting potential or active incidents by covering up errors, mistakes, and oversights, thereby contributing to an increased opportunity for the emergence of food safety incidents. Performing under a "fear culture" can be considered a barrier in the implementation of an FSMS in a food processing plant.3

Based on the authors' Blue Bell Creameries case study and the other, recent listeriosis outbreaks shown in Table 2, we may presume that these incidents are the result of either a toxic, negative "fear culture," or a laissez-faire attitude without adequate implementation of food safety management, PRPs, HACCP, or other food safety tools.3

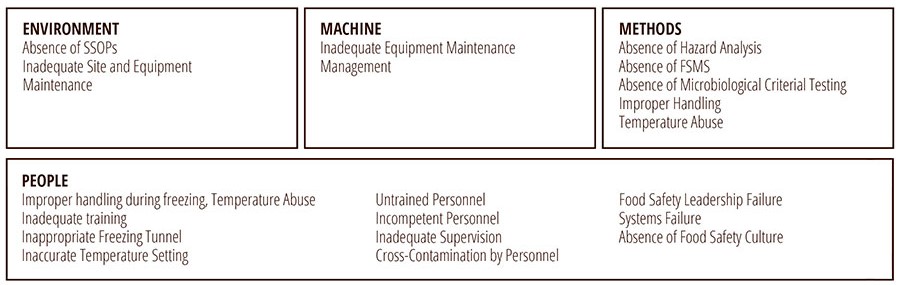

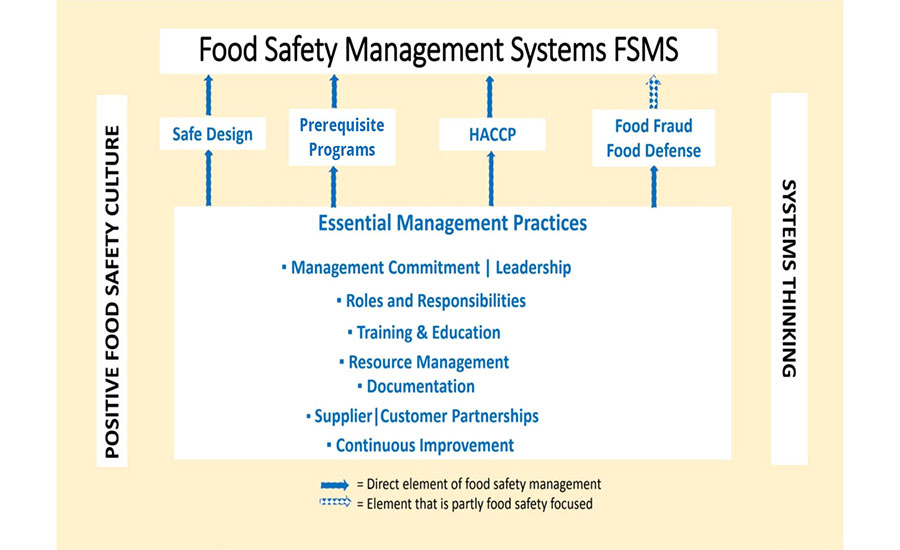

For implementing an FSMS and a food safety culture, leadership must be committed to use concomitantly several major mitigation strategies, make use of systems thinking for each phase of FSMS implementation, use HACCP and PRPs, and focus on process control as the building block of the FSMS (Figure 2). In addition, the identification and resolving of possible barriers to implementing an FSMS should be part of the managerial systems thinking process.3,12

FIGURE 2. The FSMS Building Blocks and the Systems Thinking Approach (Adapted from "What are Food Safety Management Systems?") (Lee, J.C., et al., 2021)

Using HACCP and Focusing on Process Control

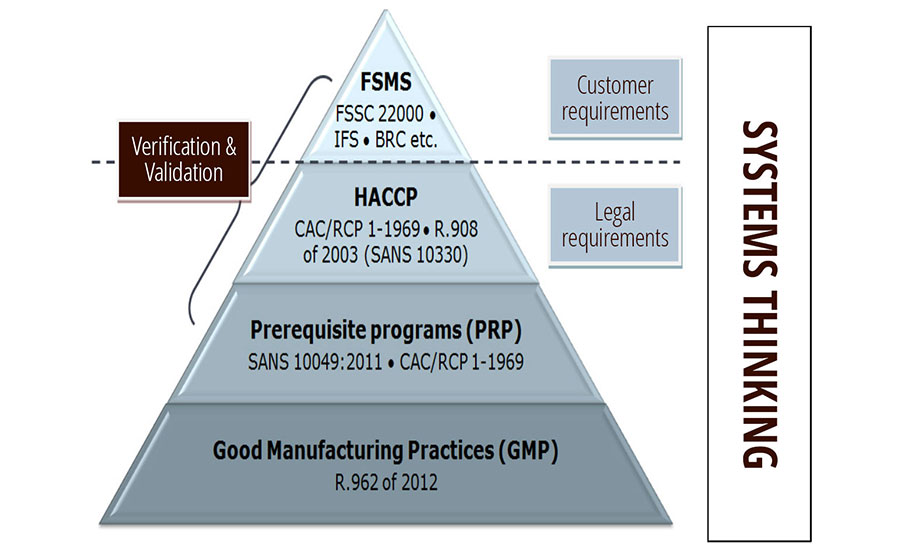

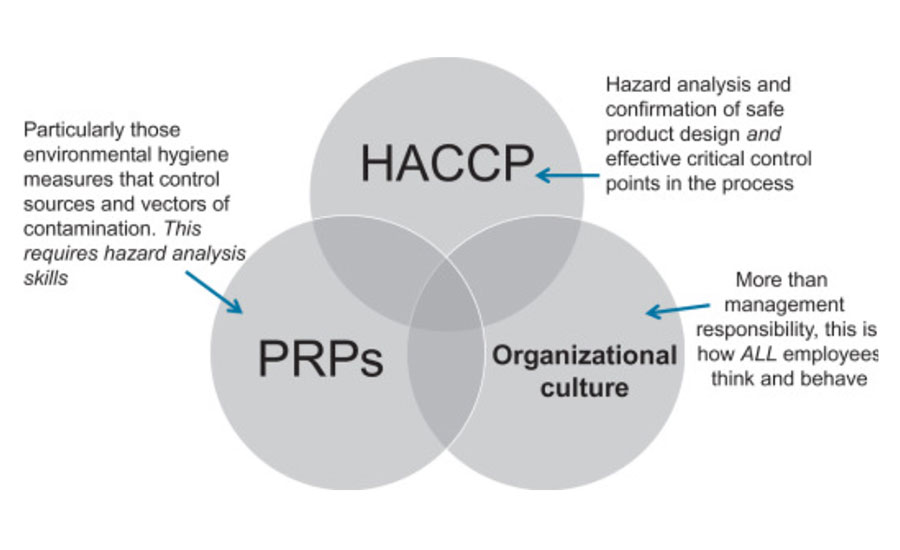

HACCP is a tool to develop, implement, and verify an FSMS. In preventing foodborne illness outbreaks, the PRPs are the foundation of a functional, viable HACCP. Both HACCP and PRPs require a systems thinking managerial approach during the development, implementation, and verification process (Figure 3).

FIGURE 3. Managerial Systematic Approach to Food Safety Using HACCP and PRPs (Adapted from Prerequisites for Food Safety: PRPs and Operational PRPs) (Lee, J.C., et al., 2021)

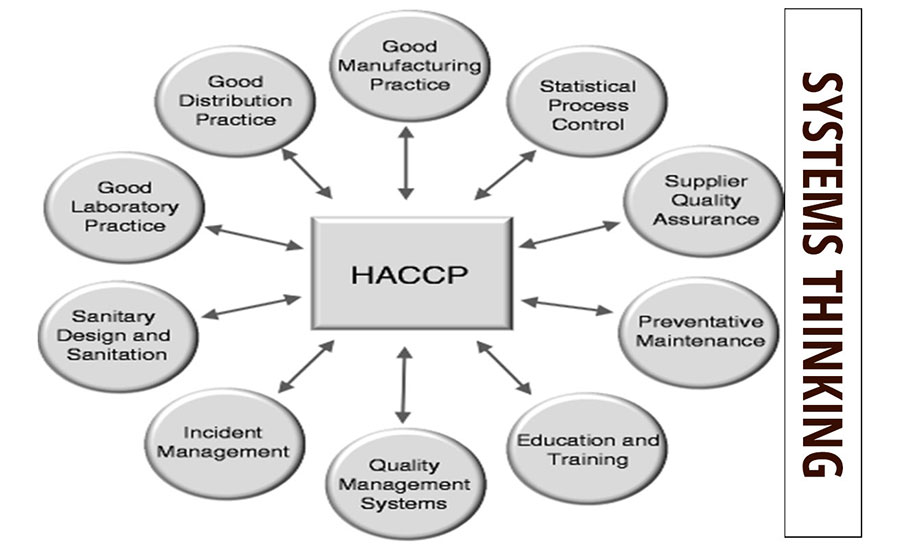

Organizational food safety culture, PRPs, and HACCP work in an interconnected and a symbiotic fashion (Figure 4).

FIGURE 4. Organizational Food Safety Culture Works in Symbiosis with PRPs and HACCP (Source: Handbook of Hygiene Control in the Food Industry, "Chapter 3: HACCP") (Adapted from C.A. Wallace and S.E. Mortimore, 2016)

PRPs are foundational components of a world-class food safety program. They have a significant support role as the "heavy lifters" among the core elements. Traditionally considered as the foundational support for HACCP, we now perceive how PRPs also play an active, indirect role in food defense, food fraud prevention and safe food processing technology and engineering. They work symbiotically with HACCP as a preventive control (PC) system. PRPs are applicable at all stages of the global food supply chain and, in turn, comprise good mitigation practices for growing, harvesting, manufacturing, storage, distribution, retail, foodservice, and the cottage industry. Figure 5 illustrates the interaction between FSMS, necessary good management practices, positive food safety culture, and systems thinking.3

FIGURE 5. Organizational Food Safety Culture Works in Symbiosis with PRPs and HACCP (Source: Handbook of Hygiene Control in the Food Industry, "Chapter 3: HACCP") (Adapted from C.W. Wallace, et al., 2018) (Lee, J.C., et al., 2021)

FSMS and Systems Thinking

Managerial systems thinking is about investigating, in a holistic manner, what factors and/or interactions are contributing to, or could contribute to, FSMS failure. Many of today's challenges are extremely complex and cannot be viewed from one perspective only; instead, they can and should be approached by looking at the system within. This makes it possible to restructure the system. Complex problems can be solved by using systems thinking, along with food safety knowledge and skills3,17 (Table 3).

TABLE 3. Examples of Food Safety Competencies, Along With Required Safety Knowledge and Food Safety Skills and Systems Thinking Approach (Adapted from "GFSI Food Safety Auditor Competencies, Edition 1," 2013)

Identified Barriers to Implementing FSMS

A lack of PRPs is the number-one identified barrier to implementing an FSMS, at 92.2 percent. A lack of knowledge about HACCP is the number-two identified barrier, at 83.5 percent. Prerequisite GHPs must be in place before an effective FSMS, HAACP plan, and operational procedures can be established. PRPs now encompass the entire FSMS and not only operational GHPs, as in the past. They also include environmental criteria. PRPs are an established foundation for the implementation of HACCP.

Meanwhile, HACCP and PRPs are not acknowledged as being interdependent. For example, they are often taught separately, with more emphasis on HACCP training and certification than on PRPs. Case in point: ISO 22000:2005 on FSMSs contained minuscule guidance on PRP requirements, so a supplemental specification on PRPs for the food industry was developed to be benchmarked and approved by the Global Food Safety Initiative (GFSI). Thus, the symbiotic significance of PRPs to the manufacture of safe food is predominantly apparent. Recalls associated with pathogens such as Listeria or Salmonella are more often caused by PRP failure (post-process cross-contamination and/or unsanitary production environments), rather than the failure or mismanagement of critical control points (CCPs) in a HACCP plan.

Deficient recycling/waste disposal and inadequate cleaning of equipment and facilities cause increases in the spoilage and contamination of food. Inferior sanitary conditions in food processing areas and unhygienic food handling adds to poor food storage and transportation, resulting in the sale and distribution of unhygienic or unsafe food. Pest or insect population activity increases the risk of food contamination and spoilage.

GMPs are designed to control the risk of food contamination with filth, dirt, scum, allergens, biofilms, chemicals, microbial particulates, and other mediums during food processing. The most frequent cause of contamination is cross-contamination of food by workers and handlers. Good food worker hygiene (GHP) is necessary because the cleanliness and behavior of workers determine the risk level of cross-contamination from worker to food products and food contact surfaces. Up-to-date food safety, food hygiene, and food handling worker training are of the utmost importance to produce safe food.

SSOPs are written to ensure sanitary conditions in food facilities. SSOP procedures are specific to a plant, but also may be similar to plants of the same or similar food sector categories. All SSOP procedures must be adequately documented and validated. When the facility's SSOPs are in a developmental stage, current GMPs could assist as a guide to the food facility.3

Process-Based Microbiological Criteria

Generally, there is agreement among academics and researchers on two main aspects to food quality: objective and subjective. The former regards the physical features of a product and is related to quality control and food technology. The latter reflects the evaluation and judgments of consumers regarding perceived product quality characteristics. In any case, while food quality is an inherently complex and multifaceted concept, it definitely has food safety at its core. Being the most essential variable for food quality, food safety is regulated to ensure that consumers purchase food products that fulfill their expectations regarding safety. To implement food quality and safety controls, it is necessary to have real-time monitoring at critical points in the process. Rapid and precise methods of analysis are vital to guarantee product quality and safety, as well as compliance with labeling. The fast detection of spoilage agents such as bacteria, pathogens, and other microbial contaminants in food production and processing is necessary to reduce spoilage and secure a safe supply of food.3

When testing results are not satisfactory to meet the type of criteria, food producers must apply the measures determined by the regulation. If there is a tendency toward repeated unsatisfactory results, then food production companies must immediately take steps to prevent the occurrence of microbial hazards. Depending on the particular characteristics of each food, companies must guarantee compliance of a given product to relevant, established criteria, without fail. Table 4 captures the main microorganisms of concern, toxins, and metabolites found in specific food categories.

TABLE 4. Main Microorganisms of Concern, Toxins, and Metabolites Found in Specific Food Categories (Lee, J.C., et al., 2021)

Conclusions

Adoption of a food safety management culture is essential in today's world, along with the implementation of ISO 22000:2018 and/or other management tools or systems. This helps food companies work toward ensuring food safety and quality, which are key parameters for business growth. Incidences of food poisoning are much more complicated these days; however, companies still fail to properly implement GMPs and/or PRPs. Violations of HACCP-based SOPs are identified by onsite regulatory inspections, as in the example of the Listeria outbreak from the Blue Bell Creameries facilities.

In this direction, food safety competencies, knowledge, and skills, along with a systems thinking approach, must be developed by employers and understood by employees. Barriers do exist in the implementation of a FSMS, but these can be overcome by applying both new and old safety knowledge. Continuous monitoring of CCPs and operational PRPs will help, along with training of personnel in new and emerging hazards and the ways to prevent them.

References

- Swainson, Mark. Swainson's Handbook of Technical & Quality Management for the Food Manufacturing Sector. Woodhead Publishing Series in Food Science, Technology, and Nutrition. Elsevier (2018). Additionally: Wayne Labs. "Food Safety Management Systems: The Right Tools Enable Long-Term Success." Food Engineering Magazine. June 9, 2014. https://www.foodengineeringmag.com/articles/92394-food-safety-management-systems.

- Powell, Douglas A., Casey J. Jacob, and Benjamin J. Chapman. "Enhancing Food Safety Culture to Reduce Rates of Foodborne Illness," Food Control 22, no. 6 (2011): 817–822. https://doi.org/10.1016/j.foodcont.2010.12.009.

- Lee, J. C., A. Daraba, C. Voidarou, G. Rozos, H. A. E. Enshasy, and T. Varzakas. "Implementation of Food Safety Management Systems along with Other Management Tools (HAZOP, FMEA, Ishikawa, Pareto): The Case Study of Listeria monocytogenes and Correlation with Microbiological Criteria." Foods 10 (2021): 2169. https://doi.org/10.3390/ foods10092169 https://www.mdpi.com/2304-8158/10/9/2169.

- U.S. Centers for Disease Control and Prevention (CDC). "Multistate Outbreak of Listeriosis Linked to Blue Bell Creameries Products (Final Update)." June 10, 2015. https://www.cdc.gov/listeria/outbreaks/ice-cream-03-15/index.html.

- U.S. FDA Observation Report. "Blue Bell Creameries Sylacauga AL Facility 04/06/2015–04/30/2015." https://www.fda.gov/media/91865/download.

- U.S. FDA Observation Report. "Blue Bell Creameries Broken Arrow OK Facility 03/23/2015–04/23/2015." https://www.fda.gov/media/91871/download.

- U.S. FDA Observation Report. "Blue Bell Creameries Brenham TX Facility 03/16/2015–05/01/2015." https://www.fda.gov/media/92059/download.

- Nalbone, L., L. Vallone, F. Giarratana, G. Virgone, F. Lamberta, S. M. Marotta, G. Donato, A. Giuffrida, and G. Ziino. "Microbial Risk Assessment of Industrial Ice Cream Marketed in Italy." Applied Science 12 (2022): 1988. https://doi.org/10.3390/app12041988.

- Donato, G., A. Giuffrida, and G. Ziino. "Microbial Risk Assessment of Industrial Ice Cream Marketed in Italy." Applied Science 12 (2022): 1988.

- Kozak, J., T. Balmer, R. Byrne, K. and K. Fisher. "Prevalence of Listeria monocytogenes in foods: Incidence in dairy products." Food Control 7 (1996): 215–221.

- "Food science expert explains why Listeria is showing up more often in food recalls." K-State News, Kansas State University. May 5, 2015. https://www.k-state.edu/media/newsreleases/may15/listeriarecalls5515.html.

- Macheka, Lesley, et al. "Barriers, benefits and motivation factors for the implementation of food safety management system in the food sector in Harare Province, Zimbabwe." Food Control 34, no. 1 (2013): 126–131. https://doi.org/10.1016/j.foodcont.2013.04.019.

- "What are Food Safety Management Systems?" https://chimerasystems.co.za/services/fsms/.

- Wallace, C. and S. Mortimore. "Prerequisites for Food Safety: PRPs and Operational PRPs." In: HACCP. Springer, Boston, 2013. https://doi.org/10.1007/978-1-4614-5028-3_4.

- Wallace, C.A. and S.E. Mortimore, "Chapter 3: HACCP." Handbook of Hygiene Control in the Food Industry. 2nd Edition. Sawston, UK: Woodhead Publishing, 2016. https://doi.org/10.1016/B978-0-08-100155-4.00003-0.

- Wallace, C.W., W. H. Sperber, and S.E. Mortimore. Food Safety for the 21st Century: Managing HACCP and Food Safety throughout the Global Supply Chain. 2nd Edition. Hoboken, New Jersey: John Wiley & Sons, 2018.

- Makwela, M. "Systems Thinking Can Be Used to Solve Complex Food Contamination Problems." Center of Excellence in Food Security. Bellville, South Africa. 2016.

- GFSI Food Safety Auditor Competencies Edition 1. November 2013. https://mygfsi.com/wp-content/uploads/2019/09/GFSI-Food-Safety-Auditor-Competencies.pdf.

Aura Darabă, Ph.D., is an Associate Professor in the Department of Food Science and Engineering at Dunărea de Jos University of Galati in Galați, Romania.

Theodoros Varzakas, Ph.D., is a Professor in the Department of Food Science and Technology at the University of Peloponnese in Kalamata, Greece.

Jocelyn C. Lee is a Food Safety Consultant at GRS Inc., Gourmet In Motion. She is a SQFI and HACCP-HARPC Coordinator, and is certified in CFSPM, CFSC, and FSPCQI by the Department of Food Science and Technology at the University of California–Davis, the American National Standards Institute, and the National Registry of Food Safety Professionals.