Food Safety and Extended Shelflife are More Crucial Than Ever

The most common potential sources for foodborne illnesses are the highly perishable, animal protein-rich ingredients, specifically meats, fish, eggs, and milk and other dairy products

PHOTO COURTESY OF: Camlin Fine Sciences (www.camlinfs.com)

Natural botanical extracts, such as from rosemary, green tea, vinegar, and spices, help preserve a products’ natural flavor, color, and aroma. PHOTO COURTESY OF: Naturex SA (www.naturex.com)

Combining natural safety options, such rosemary extract and ascorbic acid, can lengthen product shelflife of bulk oils, baking and snack products even further than when used alone. PHOTO COURTESY OF: Kemin Industries Inc. (www.kemin.com)

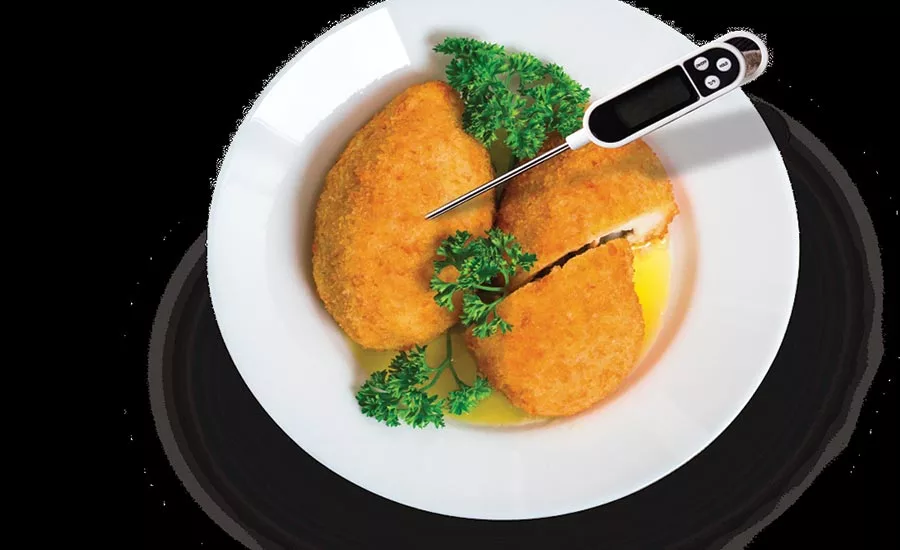

Blending spices that target specific pathogens and natural antimicrobials such as vinegar derivatives can boost flavor as well as shelflife. PHOTO COURTESY OF: Newly Weds Foods Inc. (www.newlywedsfoods.com)

Perfect Fit Meals, Houston, uses high pressure processing to enhance clean label quality and shelf life with its line of fresh prepared entrees. PHOTO COURTESY OF: PERFECT FIT MEALS (WWW.PERFECTFITMEALS.COM)

Foodborne illnesses waylay some one in six Americans (nearly 50 million people) every year, according to recent data from the Centers for Disease Control and Prevention (CDC). Of those, 128,000 end up hospitalized—and 3,000 die. This substantial public health burden is largely preventable with today’s technologies and functional ingredients.

The most common potential sources for foodborne illnesses are the highly perishable, animal protein-rich ingredients, specifically meats, fish, eggs, and milk and other dairy products. However, over the past decade or so there have been increasing instances of bacterial contamination of fruits, vegetables, and herbs. Noted culprits include cantaloupes, tomatoes, spinach, salad greens, Mexican-grown jalapeño peppers, cilantro, celery, and cucumbers.

Popular national foodservice chains such as Chipotle Grill and Starbucks have found themselves at ground zero for foodborne illness outbreaks. So have some models of healthy ingredients—for example, Earthbound Farms and Harrison Farms—thus proving that no company is immune.

Such public relations nightmares can bring even the best companies to their knees, if not shut them down permanently. When it comes to companies whose products cause outbreaks of foodborne illness, there’s a continuum of culpability. In some cases, company officials do their best and are most diligent, yet outbreaks still occur. After all, it takes but a single microbe to begin the chain of events that can lead to an epidemic. Yet there also are those companies that put profit before safety. And, of course, there’s every other company type in between. If manufacturers fail to follow the FDA’s standards, the agency can begin progressive discipline leading to mandatory recalls, fines, product seizure, and even jail time for company officials found guilty of such infractions.

Modern Times

In today’s “Food safety is Job One” era, manufacturers are generally putting forth extensive energies and resources into keeping food safe. It’s not Upton Sinclair’s “jungle” out there. After all, no one wants to sicken or kill their customers. Rather, food safety problems are likely to arise at the nexus of clean label and long shelflife. Consumers want food products free of additives and chemicals, yet they demand long shelf lives and convenience packaging.

The Food Safety Modernization Act (FSMA), signed into law in 2011, enables the FDA to better protect public health by strengthening the food safety system. It also enables the FDA to be more proactive, to focus more on preventing food safety issues rather than relying primarily on reacting to problems.

Through FSMA, the FDA received more than a dozen new authorities and mandates. For the first time, FDA attained a legislative mandate to require comprehensive, science-based preventive controls across the food supply.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

Food manufacturing facilities are required to implement a written preventative controls plan known as Hazard Analysis of Critical Control Points (HAACP). The HAACP system can be used at all stages of a food chain, from food preparation and production processes to packaging and distribution.

The FDA and the USDA require mandatory HAACP programs for juices, seafood, and meats. Meat HAACP systems are regulated by the USDA, while seafood and juices are regulated by the FDA.

Going Clean

The current clean label trend is driving many companies to ditch artificial preservatives and other additives, and that includes many of those that ensure a food or beverage stays safe. There are several high-performing synthetic ingredients used to improve food quality and extend product shelflife. These include ethylene-diamine-tetra-acetic acid (EDTA), which functions as a metal ion chelator, and antioxidants such as butylated hydroxyanisole (BHA), butylated hydroxytoluene (BHT), tert-butyl-hydroquinone (TBHQ), and propyl gallate.

These antioxidant ingredients can be used alone or in various synergistic combinations. The blends are sold as liquid, dry, and oil-soluble formulations, and work across a variety of product types, such as baking mixes, frying oils, cereals, cookies, meat products, nuts, and spices.

Since unsaturated oils are more prone to oxidative instability, natural or synthetic antioxidants help preserve both the flavor and color quality of the oils and extend their shelflife. The choice of whether natural or synthetic antioxidants are used in a product depends on the results of product stability studies to determine the best approach to extending a product’s shelflife.

The process of switching to clean-label solutions must be done with care, however. “Hormel Foods has a company-wide clean label initiative to simplify the ingredient statements of many of our retail products,” says Kevin Myers, senior vice president of R&D for Hormel Foods Corp. “We do this through the removal or replacement of ingredients, while still delivering great-tasting items that consumers expect. For example, we’re taking out ingredients such as nitrites, BHA, BHT, sodium phosphate, carrageenan, TBHQ, and hydrogenated oils.”

According to Myers, Hormel Foods was at the forefront of this trend when the company developed its Hormel Natural Choice product line in 2006. It was among the first to take advantage of high-pressure processing (HPP) technology.

“Hormel Natural Choice products were formulated with a simplified ingredient statement in mind and are 100-percent natural with zero preservatives, no artificial colors or MSG, and no nitrites or nitrates added,” says Myers. (Naturally occurring nitrites are in celery juice and cherry powder ingredients used as natural preservatives.) “The products also are gluten-free,” he adds.

Natural Science

While lactate (lactic acid) had been a standard preservative for protecting fresh and ready-to-eat (RTE) meat, poultry, and fish products from a variety of pathogens—including potentially deadly Listeria monocytogenes bacteria—the USDA recently allowed processors to utilize propionic acid as an alternative antimicrobial agent for RTE deli meats.

Both sodium lactate and sodium diacetate (vinegar-based ingredients, such as buffered vinegar) have been an industry choice. Such ingredients are particularly good for clean label chilled-food preservation. Depending on the form and the target product, they can even pull secondary duty as flavor enhancers. Some ingredient companies can even include spice oils that target specific pathogens and boost flavor. They can be labeled as “vinegar “and “natural flavors.”

As an organic acid, sodium propionate is more effective at inhibiting Listeria than acetic acid, lactic acid, or citric acid. Either vinegar-based ingredients or sodium propionate can be added to brines, marinades, spice blends, or directly to meats. Sodium propionate is typically used at levels up to 0.5%.

Manufacturers also have more “natural” options to protect their products through shelflife. There is an acerola (Malpighia emarginata) extract, derived from a type of cherry and rich in ascorbic acid, a natural antioxidant a.k.a. vitamin C. Acerola extract can help delay color loss in red meats by retarding the oxidation of the iron ion in the myoglobin molecule, and it can also be used to accelerate curing reactions in meats made with natural sources of nitrite.

Plant-derived antioxidants are another choice for protecting foods against color and flavor degradation. They work well at extending the shelflife of products with a high fat/oil content. Of these, the most common is vitamin E as tocopherol. (While the tocotrienol form of vitamin E is a far more powerful antioxidant, it is costlier than tocopherol and better suited to products that take advantage of its impressive health properties.) However, new botanical antioxidants have been moving up quickly.

Rosemary and green tea extracts are examples of such botanical preservatives. They typically can be used alone or in combination to protect food products from oxidation during production and at market. Rosemary contains a number of phytochemicals, including rosmarinic acid, camphor, caffeic acid, ursolic acid, betulinic acid, carnosic acid, and carnosol.

Polyphenols found in green tea include epigallocatechin gallate (EGCG), epicatechin gallate, and other epicatechins and flavanols. These compounds not only have strong antioxidant capacity, they also have been studied for anti-carcinogenic and anti-inflammatory benefits.

In the bakery and snack world, microbial spoilage is a major factor affecting product shelflife. Products with high water activity, such as tortillas, are particularly susceptible to mold formation.

A liquid propionic acid solution can be added homogeneously, directly to the dough, thus eliminating any irritating dust that would be generated from using powdered preservatives. This solution can increase dough softness, moisture retention, and finished product flexibility while preventing mold growth in tortillas.

Alternative label-friendly ingredients for fermented dairy products such as yogurt or sour cream can be hard to come by. Traditionally, potassium sorbate has been used to prevent the growth of yeasts and molds, and while effective, it can also impact taste and is not label-friendly.

One dairy culture manufacturer has found a solution for avoiding sorbates by utilizing a combination of patented strains of Propionibacterium and Lactobacillus. On an ingredient label, a manufacturer can just list these added strains as “cultures” or even the individual names of each culture.

Victory at Sea

Carrageenan, a natural polysaccharide from seaweed, extends shelflife through its gelling, thickening, and stabilizing properties. Because carrageenan forms strong bonds with food proteins, it is used most often as a stabilizer and to improve texture, especially in highly perishable meat, poultry, and dairy products.

Gelatinous extracts of Chondrus crispus (Irish moss) seaweed have been used as food additives since approximately the fifteenth century. As seaweed derivatives, these compounds make excellent vegetarian and vegan alternatives to gelatin to use in animal product analogs, and are used to replace animal-derived gelatin in confectionery.

Carrageenan came under fire a few years ago after poorly researched reports went viral. Carrageenan has been widely used in manufactured foods for nearly a century. Even though regulatory agencies throughout the world have studied carrageenan extensively and have approved it as a safe food additive, a recent re-evaluation took things a step further.

Last April, the USDA’s Agricultural Marketing Service rejected the opinion of the National Organic Standards Board (NOSB) and decided to keep carrageenan on the National Organic Program’s list of permitted ingredients. Now, organic food companies may keep using carrageenan in foods such as ice cream, high-protein drinks, and other formulations.

This was a welcome victory, as no other natural ingredient can replace carrageenan when it comes to matching its distinctive organoleptic and mouthfeel properties in food products.

Under Pressure

Experiments into the effects of pressure on microorganisms were recorded as early as 1884, and reports on the effects of pressure on foods quickly followed. HPP of food products involves a cold “pascalization” technique. This is where the products, already sealed in their final packages, are introduced into a vessel and subjected to purified water at pressures ranging from 43,500-87,000 psi.

Pressures above 58,000 psi at ambient or refrigerated temperatures inactivate the vegetative flora (bacteria, virus, yeasts, molds, and parasites) as well as enzymes present in food, thereby extending the product’s shelflife and guaranteeing food safety.

Overall, global revenue for the HPP food products and equipment market is above $13 billion, with strong revenue growth predicted through 2027, according to the report, “Food High Pressure Processing (HPP) Technologies Market 2017-2027,” by Visiongain, Ltd.

HPP allows manufacturers to virtually eliminate preservatives while preserving the flavor, color, and texture of foods. Moreover, no heat treatment required. Food products can be in their final packaging and be either vacuum packaged or use modified atmosphere packaging.

“HPP is the best method of preserving foods without compromising quality,” says Guy Ironi, CEO of Nutrifresh Services LLC. “HPP products retain their shape, because water pressure is applied in all directions uniformly for about one to three minutes. The growth of HPP has extended to meats, juices, ready to eat (RTE) meals, even pharmaceuticals. As long as the product has at least a 0.85 aW (water activity), even cooked pasta or prepared salads can be successfully treated using HPP.”

Safety in a Flash

There are several super-premium refrigerated juice and smoothie brands using either HPP or flash pasteurization to kill microbes without killing flavor. PepsiCo.’s Naked Juice, Campbell Soup Co.’s Bolthouse Farms, Suja Juice Co., and The Coca Cola Co.’s Odwalla Inc. are prominent examples. Often, the juices and puréed fruit ingredients used as the base for these products are cold-pressed (using a hydraulic press) to preserve the color, flavor, and nutrients.

Generally, these products are marketed as all-natural and do not contain any added preservatives. The safety and quality of the packaged products are maintained against bacterial spoilage with either the aforementioned HPP or a flash-pasteurization methods.

Flash pasteurization, also called HTST processing (“high-temperature short-time”), is a method of heat pasteurization for perishable beverages like fruit and vegetable juices, beer, wine, and some liquid dairy products. The liquid moves in a controlled, continuous flow while subjected to temperatures of 71.5°C (160°F) to 74°C (165°F) for about 15 to 30 seconds.

The standard US protocol for the flash pasteurization of milk, 71.7°C (161°F) for 15 seconds, was established in order to kill Coxiella burnetii, the most heat-resistant pathogen found in raw milk. The process was introduced in 1933, and results in a five-log or greater reduction (99.999%) in harmful bacteria. Tropicana Products Inc., now owned by PepsiCo., was an early adopter of flash-pasteurization, using the method since the 1950s. Odwalla switched from non-pasteurized to flash-pasteurized juices in 1996 after tainted unpasteurized apple juice containing E. coli O157:H7 sickened many children, killing one.

Although HPP-treated products are not shelf stable and must remain in the cold chain, they do not need preservatives. The high pressures involved inactivate all of the pathogens present, while preserving vitamins and minerals and extending shelflife.

Other mechanical sources of microbial protection include ultraviolet (UV) light, radiation, and steam. UV pasteurization has been used for more than half a century. Fairly common even today, this method kills microbes and even viruses by frying their DNA.

UV treatment (sometimes labeled as a “cold pasteurization” process) is comparatively cheap and has proven useful for frozen and baked products, juices and other beverages, cheeses, shelled and liquid eggs, and ingredients such as whole grains and certain sweeteners. It also is used on the more hardy types of fresh produce.

Irradiation was briefly heralded as a panacea in the 1990s, but it had a number of drawbacks. Although still used for some ingredients such as spices, issues ranging from cost to public rejection (valid in the case of the process that used radioactive isotopes, but misguided as far as electron-beam radiation) kept the process from widespread usage.

The latest in steam technology, currently in use on the ingredient side, involves using pressurized steam that yields what is termed “dry saturated steam.” Unlike other heat treatments, this technique allows for lower treatment temperatures, achieving 5-log reduction in pathogens, especially Salmonella. Moreover, it does not result in loss of flavor or texture quality. It’s an especially effective method for treating delicate food products.

Critter vs. Critter

Beneficial bacteria are known to control harmful ones through a “survival of the fittest” paradigm. In fact, this is one of the benefits of probiotics when it comes to digestive health. The same concept can be applied when it comes to food safety. An example is the compound natamycin.

While not an antibacterial, natamycin has a history of safe use as a natural mold and yeast inhibitor in cheeses, meats, and other food products. A by-product of the bacteria Streptomyces natalensis, it was discovered in the mid-1950s and a little more than a decade later, after techniques for production via fermentation were perfected, gained approval as a food additive applied to the surface of cheeses and to shredded and crumbled cheeses for mold and yeast control. It has been known to extend shelflife to up to 5 weeks or more in some products. Recently, the FDA has permitted the use of natamycin in yogurts.

The use of beneficial microbes to prevent growth of harmful ones is an area of ongoing research. So, too, is the expansion of use of botanicals. In fact, botanicals remain one of the most promising sources for natural, clean-

label microbial protection. But this is not new; Indian culinary practices have used such ingredients as cloves and cinnamon for centuries to preserve foods.

Modern science confirms their efficacy. In fact, the volatile chemical compounds in these spices have been shown to act as some of the most powerful antibacterial agents known. The future of food protection is not only natural, it’s flavorful as well.

A True Original

Salt was the original preservative, being used for thousands of years to prevent microbial contamination and extend the shelflife of perishable and seasonal foods, such as meat, fish, vegetables, and dairy

products. However, decades of misinterpreted, misapplied, and, in some cases, misleading reports

demonized salt. Even today, while scientific re-evaluations have shown that there is little evidence to definitively support the reduction of sodium in the diets of healthy persons, many manufacturers, usually bowing to residual consumer demand, still seek to lower sodium in their formulations. Nevertheless, salt is a powerful natural preservative and, in the right formulations, it could merit reconsideration.

HACCP in 7 Steps

The written preventative controls plan of HAACP involves seven principles: (1) evaluating the hazards that could affect food safety, (2) identifying what preventative steps or controls (critical control points) will be implemented to significantly minimize or prevent the hazards, (3) establishing critical limits for each critical control point, (4) establishing critical control point monitoring requirements specifying how the facility will monitor these control points to ensure they are working, (5) specifying what corrective actions the facility will take to fix problems that arise when there are deviations from the established critical limits, (6) establishing procedures for ensuring the HAACP system is working as intended, and (7) maintaining routine records of the monitoring of the critical control points and handling of any processing deviations.

PB & Jail

When an American comfort food staple such as peanut butter is at the center of a serious food poisoning outbreak, it can be especially egregious. An example is a huge outbreak of Salmonella due to tainted peanut butter in 2008. The now-infamous outbreak, with the deadly microbe traced to peanut butter paste manufactured by the Peanut Corporation of America (PCA), killed nine people and sickened 714 others, some critically.

Spreading across 46 states, it was one of the deadliest salmonella outbreaks on record and resulted in one of the largest food recalls in American history, involving hundreds of companies and nearly 4,000 different products, including some highly popular brands. Products from Keebler Co. brand peanut butter crackers to Famous Amos cookies and even the snack packets handed out on airlines were subject to the recall action.

At the time, PCA was one of the leading peanut processing companies in the US, providing some 2.5% of all processed peanuts in the country. But the company also had been in trouble repeatedly for nearly two decades for slipshod food safety practices. In 2015, the CEO and owner of PCA was given a 28-year prison sentence, the toughest penalty ever for a corporate executive in a food poisoning outbreak. He got off easy. In China, two executives involved in a melamine-tainted milk scandal were executed.

Originally appeared in the September, 2018 issue of Prepared Foods as Safe and Long.