Eliminating Contamination from Food Processing

Food processing has become one of the largest industries in the world and often goes through upgrades and capital equipment purchases to maintain the cleanest and highest quality products for the consumer. Among the operations performed by food processing plants are deboning chicken, turkey and duck. Most deboning machines are designed and manufactured mainly to debone the body and skeleton of the poultry. The processed meat is suitable for producing sausage, meat patties, meat balls, and much more.

Foodmate USA manufactures deboners for the food manufacturing industry. The machines are used all over the world. A particular machine was being used in the deboning operation by a Dutch food manufacturer. The FM 8.50 Turkey deboner was designed for turkey thighs, drumsticks and primary wing segments. Its heavy-duty mechanical design is easy to load, while using only one operator (Figure 1).

Foodmate USA manufactures deboners for the food manufacturing industry. The machines are used all over the world. A particular machine was being used in the deboning operation by a Dutch food manufacturer. The FM 8.50 Turkey deboner was designed for turkey thighs, drumsticks and primary wing segments. Its heavy-duty mechanical design is easy to load, while using only one operator (Figure 1).

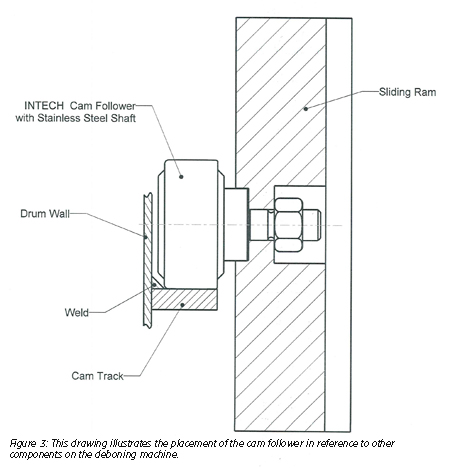

The FM 8.50 simple design builds on a stationary, drum-like structure. Rotating around the drum are 12 actuators, called rams, driven by a self-lubricating gear mounted on top of the drum, and propelled up and down by cam followers that ride along one double cam rail. The machine has a small footprint and is easy to clean and maintain (Figures 2 and 3).

The FM 8.50 simple design builds on a stationary, drum-like structure. Rotating around the drum are 12 actuators, called rams, driven by a self-lubricating gear mounted on top of the drum, and propelled up and down by cam followers that ride along one double cam rail. The machine has a small footprint and is easy to clean and maintain (Figures 2 and 3).

With 12 separate stations, the FM 8.50 provides a high throughput of up to 45 segments per minute. After an operator places the product onto the holder, a cam-driven plunger forces the bone through a rubber diaphragm to strip meat from the bone as it is being pushed through the machine. A cutter blade separates the bone from the meat (Figure 4), and then the meat is discharged by an unloading unit. Once the meat is output it can be packaged or, most often, go directly to a grinding operation.

The cams follow a curved track, which goes through three stages of pushing the bone from the meat. First the plunger pushes the bone into position, then shoves it part way through, and then forces the bone the rest of the way out. The last operation requires high force and produces the most shock, which is where the greatest challenge occurred.

The FM 8.50 represents an improved design as a deboning machine, focusing on economy of design as stated by the customer. The system is constructed from stainless steel, including the double cam rails welded to the outside wall of the drum. Where typically cams are made from steel, and are precision machined, ground and case hardened, the FM 8.50 instead used a double cam profile created from two 8 mm × 20 mm rectangular stainless steel bars spaced 50 mm apart that were welded to the drum, with a wall thickness of 3 mm.

Welding parts of two different thicknesses led to distortions of the cam rail in more than one plane. This meant that, in several locations, the 20-mm cam rolling surface that protruded from the drum was not perpendicular to the drum, forcing the metal cam follower to run on edge and without sufficient lubrication. Resulting metal-to-metal contact combined with the high-frequency shock loading of the deboning operation caused excessive wear of the metal cam followers originally selected for the design. Having tried another metal cam follower design with the same results, Foodmate contacted Intech, who manufactures high performance plastic cam followers.

Through communication and coordination with the food manufacturer’s engineering staff and Intech, the team came up with a cam follower design and delivered a prototype within about 2 weeks. Actual measurements from the machines themselves were taken to account for the cam rail distortions not reflected in the design drawings, and to give Intech accurate information to work with. A video of the operation was also taken so that all parties could actually see some of the problems that were occurring. After receiving approval for the basic design, minor modifications were possible. For example the shaft had to be adjusted slightly.

Intech engineers designed a crown on the cam follower to better conform to the rail. Further, a 5-mm relief was included on the sides of the cam follower to clear the weld. Two heavy-duty, precision ball bearings and a stainless steel shaft completed the design. The design worked perfectly. The Power-Core™ cam followers absorbed the shock of the deboning operation and compensated for the uneven contact surfaces without wearing out. Enough cam followers were ordered to run one of the three machines at the manufacturer’s processing plant. Soon after, the remaining machines were retrofitted. With Intech cam followers, Foodmate achieved a reliable linear motion solution that does not require a case hardened and ground cam.

Additional benefits to using the Intech Power-Core technology for the plastic cam followers were great. Since the design for the deboning machines needed to comply with food safety, the Intech cam followers were ideally suited. The components used stainless steel bearings as well as a stainless steel shaft, but because of the nature of the custom formulated Intech materials used for the cam followers the components never require lubrication and can be washed down to food industry requirements. Benefits from selecting polymer cam followers to run on a stainless steel rail, a minor change in the original design, greatly reduces downtime, eliminates wear and potential food contamination, and cuts down on maintenance costs. This type of overall affect meant that the Dutch food manufacturer was very pleased with the final outcome of the system.

For more information please visit www.foodmateusa.com and www.Intechpower.com.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →