Steer carcasses are getting heavier: what does it mean for protein processors?

In the midst of the COVID-19 pandemic, stories of plant closures and backups in the meat supply chain have dominated the news, making COVID-19 prevention the primary goal for meat processors.

But, as we continue to navigate the changes to food manufacturing as a result of the pandemic, there’s another trend you’ll want to get ahead of—increases in steer carcass weights.

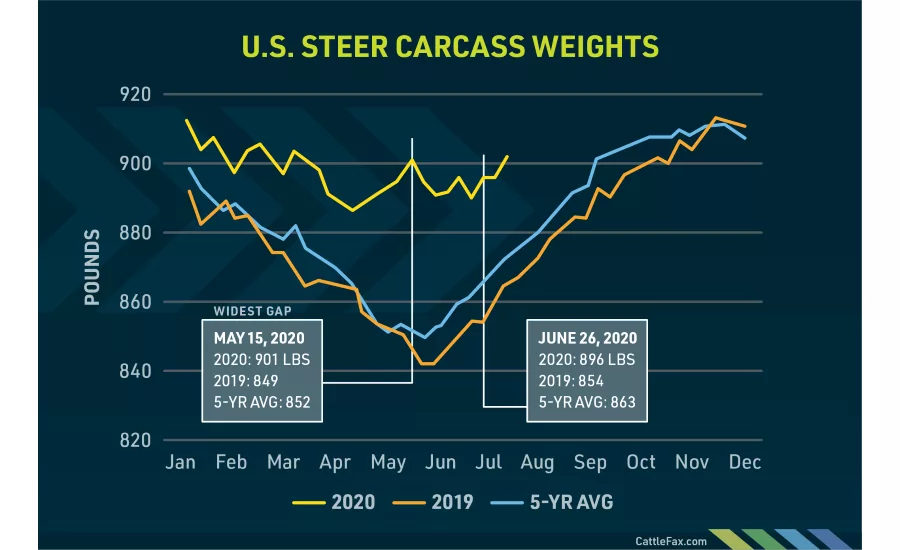

Since January of 2020, Cattlefax has tracked and plotted USDA data on steer carcass weights. The data reveals that compared to 2019 on the same dates, as well as the five-year average, steer carcasses are substantially heavier—49 lbs. more than the five-year average at the highest point (May 15, 2020). And, even with periodic drops in weight, the trend is continuing. As of June 26, 2020, U.S. steers were 42 lbs. heavier than the same date in 2019 and 33 lbs. heavier than the five-year average.

So, what does it mean for meat processors? While there are potential upsides to the shift, you’ll also need to prepare your facility for processing higher amounts of trim.

Understanding the change and addressing potential beef shortages

When the pandemic hit the United States, consumers stocked up on meat—ground beef in particular, likely due to its versatility and relatively easy preparation. At the same time, because of backups in beef harvesting, beef production dropped nearly 31 percent compared to 2019 (as of May 11, according to the USDA).

The increase in beef demand and slowed production are resulting in concerns about beef shortages in many areas of the United States, but cattle are also on feed longer than usual prior to harvest, driving carcass weights up.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

The change in carcass weights presents a valuable opportunity to address these concerns. Heavier carcasses mean more trim, which can be used to produce more ground beef and meet high consumer demand for it.

Proper sanitation: More critical than ever

Despite the potential for producing higher amounts of ground beef, processing heavier steer carcasses won’t come without challenges. During a time in which many plants are facing labor shortages, the risk of a COVID-19 outbreak, and a heightened awareness of food safety, it’s crucial that processors direct even more attention to preventing the spread of pathogens.

More frequent disinfecting of common areas and strict adherence to HAACP protocols are important, immediate measures food processors can take to get ahead of the issue, but it’s also worth evaluating your sanitation products and equipment to prepare for processing higher amounts of beef trim without slowing processes. Are you using the right chemicals and dilution? Do your processes result in complete, 360-degree coverage of beef trim every time? What processes could be automated?

Asking these questions provides you with a starting point not only in preparing for processing heavier steer carcasses, but also in saving on costs and overcoming potential labor shortages down the road. The key to coming out ahead is identifying a solution that will not only help you navigate present challenges, but will streamline your processes long-term.