Supply chains

Food fraud is not only an economic drain but also a supply chain safety concern

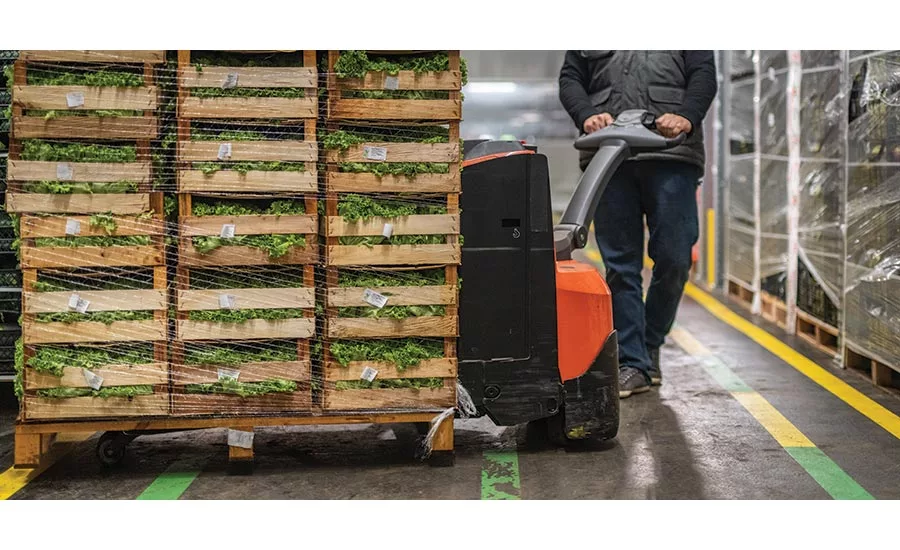

Maintaining supply chain integrity requires processors to know where their ingredients are coming from and to have a robust, verifiable process for identifying and correcting potential fraud.

Photo courtesy of Getty Images

Tracking and tracing ingredients and products throughout the supply chain and production process helps safeguard food and beverage manufacturers against potential food fraud.

Photo courtesy of Getty Images

This type of track and trace station is designed to maximize productivity in manual packaging operations, performing a reading from the top of the Data Matrix codes on cartons when fit into a case.

Photo courtesy of Antares Vision North America

Guarding against food fraud in the supply chain can be a costly, resource-intensive effort—but the potential effects of not catching it can be disastrous.

Food fraud in the supply chain is costly and can take place through various means—the most common being adulteration by substitution, omission, dilution, falsification, deception in the production method or its origin, intentional mislabeling, or masking a defect or contamination.

Sarah Krol, global managing director of food safety, NSF International

Attilio Bellman, business strategy director, Antares Vision North America

David Cahn, global marketing director, Elemica

Alma Delia Hernández, food safety professional, AIB International

Joseph Basile, president of Catania Oils

Sean Clemmons, CEO of Parity Factory

Renata McGuire, NSF International North American food fraud lead

Commonly known as economically motivated adulteration, food fraud is more prevalent in the supply chain than is widely known, according to Alma Delia Hernández, a food safety professional at the supply chain consulting company, AIB International.

“It is not a new problem either, as the practice of adulterating food for economically motivated reasons has been going on for years,” she says. “It has been in the spotlight recently because better technologies are being developed that allow it to be more easily identified.”

Sarah Krol, global managing director of food safety at NSF International, an independent, global organization that facilitates standards development and tests and certifies products, says that food fraud issues vary greatly by region and commodity type.

“While it is difficult to quantify how widespread food fraud is across the entire supply chain, experts estimate the impact to the food industry to be in excess of $50 billion annually,” she says. “Some of the commodities or food types where food fraud has been particularly prevalent or widespread are in seafood, honey, oils, spices, meat and coffee.”

David Cahn, director of global marketing at Elemica, a digital supply network provider, says that because supply chains of today are global and complex, there is an increase in food fraud.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

“According to FoodIntegrityEvent.com, only 33% of consumers are confident about the safety of their food supply,” he says.

We know food fraud varies wildly depending on the particular food vertical, says Sean Clemmons, CEO of Parity Factory, a food-specific warehouse and production management software company. “For high-value items like fish and wine, for example, fraud can be a real issue,” he says. “On the other hand, it is incredibly rare in, say, potato salad or blueberries. The industries where fraud is most prevalent have invested heavily in tagging and prevention.”

Attilio Bellman, director of business strategy for Antares Vision North America, a manufacturer of vision systems designed to make the food supply chain more secure, intelligent and transparent, cites the U.S. Pharmacopeia Convention (USP) food fraud database for stakeholders in the food supply chain with a list of more than 2,000 food fraud incidents. He adds that the Consumer Brands Association (formerly the Grocery Manufacturers Association) estimates that food fraud may cost the industry $10 to $15 billion dollars annually and may affect as much as 10% of the global food supply.

“It’s also well known that certain foods are particularly vulnerable to adulteration,” he says. “For example, almost 70% of extra virgin olive oil is said to be adulterated to some extent.”

Joseph Basile, president of Catania Oils, knows the perils of food fraud in the olive oil sector all too well. Whether it’s adulteration, selling products out of spec or containers that include less than they’re supposed to, the industry has to be on guard against several types of potential fraud.

Basile says the foodservice side is less regulated, although it is better today than 15 to 20 years ago. “And it’s not on the FDA’s radar, so dishonest practices like these still happen. Unfortunately, smaller mom and pop operations don’t normally have the resources to verify the product and in times of crisis like COVID-19, price is one of the most important considerations for these small businesses. Chances are they don’t even know that they are being shortchanged in weight of the product or its quality.”

Repercussions of food fraud

When food fraud is introduced into the supply chain, a variety of repercussions can range from minor to those with a significant impact on brand and market share. According to AIB’s Hernández, the fallout can include loss of brand credibility; economic affectation caused by unfair competition; loss of market share; disrepute of a producing area; and risk to consumer health.

“When fraud is discovered, not only is the product in question affected, but the quality and legitimacy of all products marketed by your company are questioned,” she says. “Those who market adulterated or illegitimate products severely damage the economy of companies that do not fall for this fraud. An adulterated and/or illegitimate product usually sells at a cheaper price. The consumer, unaware that they are a victim of fraud, tends to buy the cheapest thing, believing that it is the same that is sold at a higher price.”

She offers the example that the immense quantity of principally European cheeses produced outside their place of origin that instead of being marketed as “cheese type” are sold as “cheese of origin,” such as parmesan, manchego and others.

But the most detrimental food fraud is when there is risk to consumer health. If adulteration makes a product unsafe, then the damage goes from simply economic to a matter of public health.

“The fraud not only threatens the integrity of the product, but also puts the consumer’s life at risk,” says Hernández. “Recall past episodes of melanin in milk powder, adulteration with methanol in alcoholic beverages, beef with clenbuterol, among many other unfortunate cases.”

With the weak link of food fraud in the supply chain comes frustration too. Basile says that too often, consumers don’t care because they want a lower price, but the FDA and USDA are concerned with food safety. Those priorities result in instances of fraud that are not a health risk falling through the cracks.

“If it’s not killing anyone, it’s just stealing from people and there’s no time to bother with that, but they should,” Basile says. “Organic oils sell at two to three times the cost of conventional oils—that’s a big payday for fraudsters, and small business customers are often the unsuspecting victims. The same goes for cheaters in olive oil. They add what we like to call ‘the magic olive’ into vegetable oil and pass it off as 100% olive oil for 100% pure profit.”

Coronavirus disruption

The coronavirus pandemic has had a significant impact on the food industry, especially in regard to the supply chain. Although COVID-19 is not known to be transmitted through food products, the CDC has recommended operational changes to keep employees safe in food production facilities and restaurants, including social distancing, effective hygiene practices with frequent and proper handwashing stations and routine cleaning of all surfaces.

“Fortunately, we are not seeing any reports stating COVID-19 can be transmitted by the food we ingest, so it seems we are not at risk from contracting coronavirus from produce, meat, fish, etc.,” Bellman says. “From what we’re witnessing, the real threat COVID-19 poses to the food industry is that it is making the supply chain less reliable and predictable. To that end, it’s certainly been a disruptor; both supply and demand have been adversely affected by the necessary shutdowns, leading to significant revenue losses.”

Renata McGuire, NSF International North American food fraud lead, says that COVID-19 is placing additional pressures on food supply chains, as transport of food is being delayed, and some companies—including raw material suppliers—are temporarily closing due to outbreaks at their manufacturing sites.

“Pressure to find alternate sources of materials quickly poses an opportunity for food fraud to take place. Food that is vulnerable to fraud can change dependent on external pressures, such as a sudden popularity of a material or a poor growing season. This rapidly changing environment requires food companies to stay informed of potential food fraud opportunities,” she says.

Such disruption may create the conditions for unscrupulous stakeholders to cut corners by using ingredients of inferior quality or expired products to cut losses. Even suppliers that do everything by the book have had to adjust to avoid disruptions in harvesting and transportation.

“The food supply chain relies on workers who typically travel from farm to farm, even across borders, to gather produce as it ripens,” says Cahn. “Because of the pandemic, many of these workers are not working. However, some farms are adjusting by taking orders online and making home deliveries.”

Hernández says the virus has affected the supply chain in a variety of ways, each of which provides incentive and motivation for criminals to commit food fraud. She outlines four main causes:

- Lockdowns. She says some governments have implemented social distancing measures, while some vulnerable populations have had to be absent from their jobs to minimize their risk of contracting the disease, each of which has led to a reduction in the number of active operators in the plant. The consequence has been a decrease in production.

- Shortage of materials. She says this originated when some raw material producers in the first impacted countries stopped distributing raw materials. This created a domino effect, impacting production in the next links in the chain.

- Globalization. She says the dependence on materials imported from countries with infected food manufacturing workers has put the continuity of the supply chain at risk. International trade has been hindered due to the lack of appropriate logistics, with closed borders and the decrease in the availability of transportation preventing materials from arriving on time.

- Loss of purchasing power. Because the economy has been affected, she says consumers need to buy products at the lowest cost. As a result, the vulnerability of the products becomes higher.

“Given these scenarios, some fraudsters may be tempted to try to obtain some economic gain through the intentional adulteration of the food,” Hernández says. “They may choose to send clients lower quality materials, or they have been replaced, diluted or modified without declaration. They may be taking advantage of the fact that clients have fewer personnel to supervise the reception of the materials due to the pandemic.”

NSF’s Krol says that COVID-19 has shown us that food companies must have contingency plans in place for assuring the continuity of their critical ingredients, inputs and packaging, as well as assurance that they can keep employees working under safe conditions. “While some companies have swiftly and successfully implemented changes to assure worker protection, other food producers have found this more challenging.”

The lessons learned from the COVID-19 pandemic will very likely result in a more robust, resilient supply chain that will be better prepared in the future to weather supply chain pressures.

“Food producers that can demonstrate continuity, consistency and safety of food while protecting their workers will have an undoubted advantage and be viewed as trustworthy both by retailers and consumers at large. Additionally, we can expect the industry to rely more heavily on data and digitalized information flows to better predict and prepare for supply chain disruptions in the future,” Krol says.

Clemmons says the pandemic has forced processors to adapt in a number of ways, but food safety and the supply chain in general have held up well thanks to processors focusing on ensuring their standards aren’t slipping.

“Changes in consumer habits have concentrated wastage and loss in specific sectors, creating real pain there,” he says. “But the industry has adjusted incredibly to meet new habits.”

From Basile’s perspective, some retailers are struggling to keep products on the shelves while others are having supply issues and are buying from any operation that can sell them product, even if it’s not their regular supplier.

“Often, these sources are not properly vetted and purchasing outside the supply chain can lead to fraud. I’ve seen a lot of funky-looking packages that aren’t normally on the store shelves, and I wonder about the content and quality of the oil contained inside,” he says.

For more information:

AIB International, www.aibinternational.com

NSF International, www.nsf.org

Parity Factory, www.parityfactory.com

Antares Vision North America, www.antaresvision.com

U.S. Pharmacopeia Convention (USP), www.usp.org

Catania Oils, www.cataniaoils.com

Elemica SEE, www.elemica.com/solutions/see