How a warehouse execution system assists with recalls

Don’t rely on an ERP system to manage all aspects of your warehouse—not if you need real-time connectivity.

A recent study performed by the Food Marketing Institute and Grocery Manufacturers Association, revealed that one recall can cost a food or beverage company an average of $10 million, not including lost sales profits and a tarnished brand reputation.

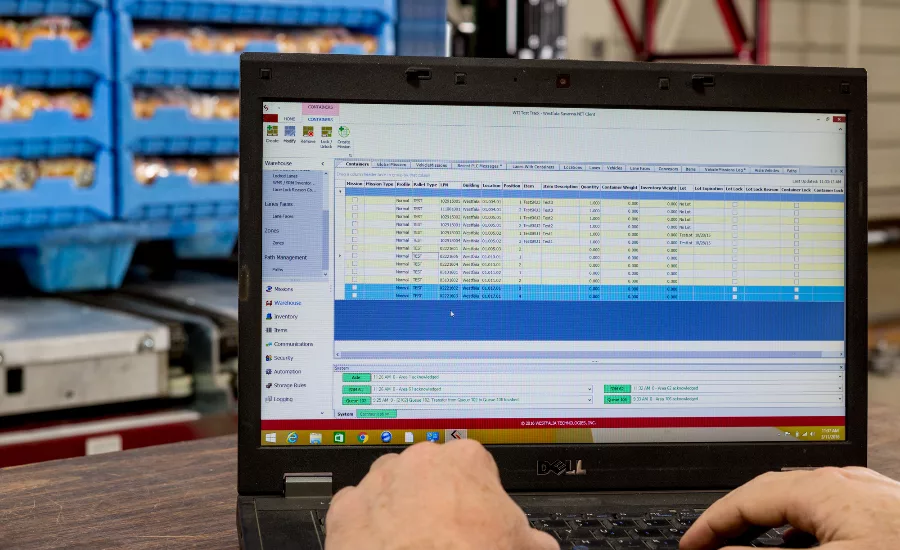

However, food and beverage processors can respond to problems within the manufacturing process more quickly by connecting a warehouse execution system (WES) to external systems both upstream and downstream in the supply chain. This will often prevent contaminated products from ever leaving the facility, saving the processor both time and money.

FE spoke with Dave Williams, Westfalia Technologies’ vice president of software development, to get a more detailed picture of how a WES integrated with other systems can not only help manage a recall process, but also prevent bad products from going out the door in the first place, thus preventing a recall.

FE: What role does a WES play in recalls?

Dave Williams: By providing a high-degree of product traceability, an integrated WES can help manufacturers discover and act upon issues that have caused the malfunction or contamination sooner. Earlier detection often allows manufacturers to better understand what product is to be recalled, thus possibly reducing the scope of the recall effort and targeting the affected inventory.

FE: What exactly are the modules contained in a WES?

Williams: Conceivably, most of the modules within a WES can be used to execute the recall process. Quality control, receiving and returns processing, labor management, equipment control and reporting are a few modules that play key roles in smoothly executing a product recall

FE: What systems should a WES be able to connect to or integrate with and exchange data? For example, ERP, MES, LIMs, supply chain management systems, etc.?

Williams: A well-designed and implemented WES should be able to easily connect to, and communicate, with any system that can send and/or receive information.

FE: Some ERP systems have a warehouse management function. Why not just use that?

Williams: Using a WMS to help manage a recall might be sufficient for non-automated facilities, but once automation is introduced, the need to effectively orchestrate both manual and automated tasks becomes crucial.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

FE: How can a WES speed up the recall process?

Williams: By utilizing a WES that is tightly integrated with other supply chain systems, manufacturers are able to more quickly and easily identify products that are part of a recall. Further, companies can utilize the information from the WES to provide their customers with the necessary information needed to identify and return the recalled product efficiently, saving both the company and its customers time and money.

FE: Can a WES also manage location of trucks in transit, or is that the responsibility of a different (fleet management) system? If so, how should the fleet management system integrate with the WES?

Williams: A fleet management system is typically responsible for managing the location of vehicles in transit, but connecting these systems to a WES provides complete, integrated visibility of a company’s orders through the time of delivery. Should the need for a recall arise, a WES that interfaces with other systems in the supply chain, like fleet management systems, allows a company to identify where the affected product is and take the appropriate action much more quickly.

FE: How can a WES help with returns?

Williams: A well-managed recall process is a must to process recalled product accurately and efficiently. There are many different recall scenarios that a manufacturer must be prepared to handle. Should the products be discarded? Is special handling required? Do the products need to be quarantined for further inspection? Are there specific reporting requirements that need to be completed? Many of these processes can be automated within a WES to guide individuals through the process, thus ensuring a complete, well-organized, well-documented, efficient handling of the affected product.

FE: How can a WES help manage recalls?

Williams: A WES that is integrated with manufacturing processes can also be used to recognize issues and provide automatic alerts to the warehouse when products are contaminated to keep the product in-house, thus eliminating the recall process. This allows the manufacturer to more easily identify and locate affected products before they leave the warehouse.

Contaminated products are potentially hazardous to the end customer, but could be extremely detrimental to a company’s financial health as well. By implementing a tightly integrated WES into the supply chain process, manufacturers are able to quickly identify, track and efficiently recall contaminated or malfunctioning products when necessary—saving time, money and often their reputation.

FE: How does the use of a WES compare in cost to just using an ERP for the warehousing function? What more can a user expect from a WES compared to using just an ERP’s warehousing function?

Williams: In my opinion, clearly defining the roles of each system is crucial to the success of any effort to integrate systems and processes. ERP systems are traditionally designed to handle the “front-end” and “back-end” tasks of the order fulfillment process. That is, functions like order capture and planning and billing functions are things that an ERP does well, while a WES is designed to handle the inventory management and order fulfillment operations within a facility. When the lines of responsibility are clearly defined, each system can perform the tasks that it does best and the entire process runs much smoother.

FE: Is a WES more real-time in nature than using an ERP’s warehousing functionality?

Williams: When it comes to communicating with automation, a WES is more tightly integrated with the equipment than a traditional ERP system might be. Also, because a WES is designed to communicate with and direct the actions of automation, as well as those in a conventional warehouse, it can perform these tasks seamlessly.

FE: Does a WES integrate with or control robotic automation on the plant floor?

Williams: Absolutely. The warehouse control components of a WES not only communicate to, but also coordinate the efforts of various pieces of automation, which helps to make the entire order fulfillment process more efficient.

FE: Anything I should have asked but didn’t?

Williams: As more companies turn to automation to produce, manage and deliver their products, the role of a well-designed WES continues to become mission-critical for managing inventories, while quickly and efficiently fulfilling ever-increasing order demands. Integrating a WES with other systems within a company’s supply chain allows for total traceability across the lifecycle of a product and provides tremendous efficiencies through-out the entire order fulfillment process.

About Dave Williams:

Dave Williams is the vice president of software development for Westfalia Technologies Inc. (Westfalia), a leading provider of logistics solutions for plants, warehouses and distribution centers since 1992. Williams spearheads Westfalia’s software and solutions delivery operations. In his role, he provides leadership and guidance for the design and implementation of solutions that contribute to strategic business goals while aligning with the overall information systems architecture.

This article was originally posted on www.foodengineeringmag.com.