Optimizing cold chain operations with LoRaWAN

In the agriculture market, sensor data is enabling farmers to operate more effectively. The rollout of rural wireless networks and the adoption of connected devices with new and innovative sensing technologies are helping to increase crop yields, improve livestock management and better allocate resources. Air and soil sensors, for example, are providing farm owners with real-time data that allow them to optimize growing conditions. Smart irrigation systems are minimizing water loss. And field management and vegetation control systems are enabling farmers to monitor the state of their crops, providing real-time data that can be used for accurate harvest forecasting and improved crop quality.

The benefits delivered by these Internet of Things (IoT) network and sensor technologies don’t stop at the farm. The same underlying technology used in the field can be leveraged to enhance delivery services, and ultimately contribute to process automation in which harvested perishable goods and fresh foods can be delivered based on real-time supply and demand. Being able to accurately track goods and assets as they move through the supply chain is allowing farmers, distributors, and retailers to work together in new ways to meet the world’s food demands while safeguarding public health and protecting the environment.

Monitoring and reporting temperature at all stages of the supply and distribution process, in particular, is a critical aspect of reducing food waste and enhancing food safety. Even a brief interruption in temperature can lead to waste, the risk of foodborne illnesses, and a failure to meet industry regulations. In fact, improving cold chain infrastructure is noted by the Commission for Environmental Cooperation (CEC) to be one of the key ways to reduce food loss and waste which is reported to be 1.3 billion tons globally, on an annual basis.

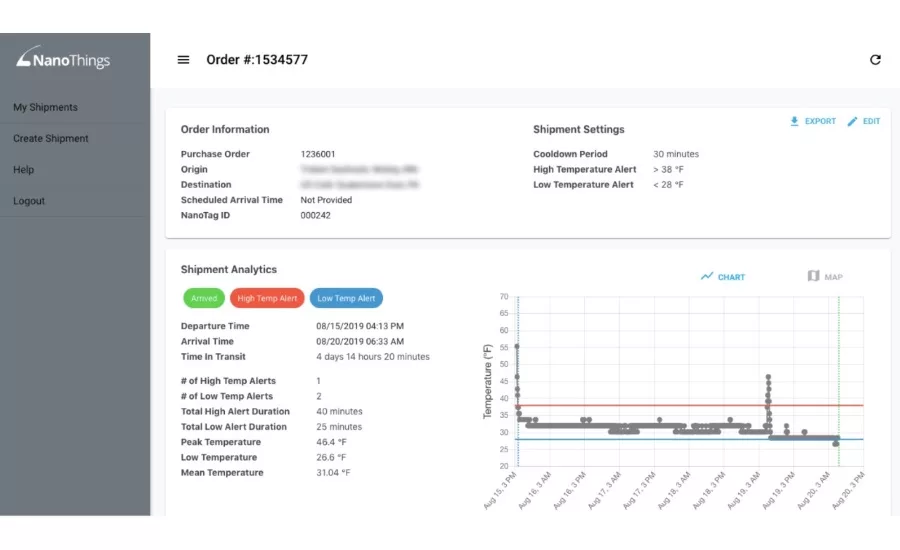

An ideal wireless technology for cold chain and location monitoring (and the above-mentioned farming solutions) is LoRaWAN, a Low Power Wide Area networking protocol characterized by low-cost, long-range connectivity and low data rate transmission which extends the life of battery-operated sensors. Partnering to deliver LoRaWAN cold chain applications are companies such as Senet and NanoThings. Senet operates the largest LoRaWAN network in North America and NanoThings has developed long-range temperature tracking smart labels and a platform for temperature monitoring, cold chain management, and intercompany communication. Combining the affordability and a small form factor of NanoThings’ NanoTags with network connectivity from Senet offers customers autonomous temperature monitoring and touchpoint tracking that has the potential to transform how data on perishable goods is collected and used throughout the retail supply chain.

This combination of IoT networks with flexible deployment models (available in public, private or semi-private configurations), advanced sensor and tag technology, and a scalable cloud-based monitoring platform provides a modern, integrated, and cost-effective solution to an industry bogged down by archaic, cumbersome, and costly technologies and processes.

Although passive monitoring devices such as data loggers are commonly used within the cold chain, companies moving to real-time solutions are able to take preventative action instead of reacting to mechanical failures, delivery delays or human error. With today’s cloud-based platforms, data for a single shipment or the entire supply chain can be viewed on-demand to support 24/7 monitoring and response operational services. Reporting and data analytics can be easily accessed, shared between required parties and analyzed to help drive future process improvements.

Using sensors, tags and other wireless technologies to track assets and goods through the global supply chain is one of the fundamental use cases for the Internet of Things. It is also one of the most impactful, with trillions of dollars of economic value being generated by the delivery of goods to consumers. Further modernizing the supply chain with new and cost-effective, easy-to-deploy wireless technologies is providing unprecedented efficiency, not just for large manufacturers, but also for producers, distributors, and retailers of any size.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →