Unique sanitation considerations in legal cannabis edibles and beverages processing

With cannabis now legal in 11 states, the cannabis edibles and beverages segment has been growing. However, with that growth comes unique concerns and considerations about the packaging, distribution, and overall welfare of these edibles and beverages, before they are released to the public.

Goodway Technologies, Stamford, CT, says that although its knowledge of the cannabis production market is still evolving, it is on their radar.

“Most of our food and beverage customers are NOT in the cannabis business … yet. The strategic value to them may be large, but the regulatory and legal ramifications still weigh heavily. However, the similarities in the processing and production processes can’t be overlooked and so pivoting to this market at scale, specifically in the edibles market, is a natural transition,” says Tim Robb, vice president, marketing and strategic business development, Goodway Technologies.

Goodway Technologies has been developing solutions for a variety of markets for over 50 years. One of its fastest growing market sectors over the last decade has been in the food and beverage production business, which itself has seen a radical change in that timeframe due to product innovations, consolidation and regulatory oversight.

However, production in this market can mean so many different things, adds Robb. “First, who is making the products? Mom and pop, small-batch producers or large F&B/medical locations?” Then the target market—medical vs. recreational or mixed—requires consideration. “These involve different production processes,” he says. “Then, what form does the product take?” This can include edibles like baked goods, lozenges, gummies and beverages, among other options. And finally, how the products are packaged—either by hand, boxed/bagged solids, or vacuum packed—should factor into discussions.

“Identifying what the opportunity is and best solutions for the particular application is a process we are currently undertaking. What we do know is that the larger producers are committed following GMPs (good manufacturing processes) and SSOPs (sanitation standard operating procedures), which include oversight of machine maintenance, surface cleaning and best-in-class sanitation,” explains Robb. He notes that the dry steam belt cleaning systems from Goodway Technologies and BioSpray surface sanitation products are primed for applications in this market. “And I think that given the infancy of regulated markets—Canada, for example—this is a business that goes nowhere but up,” he says.

Lezli Engelking, founder, Foundation of Cannabis Unified Standards (FOCUS), Scottsdale, AZ, says that the cannabis industry presents some unique risks in sanitation throughout manufacturing, packaging and distribution.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

“Food safety regulations are critical to protecting the safety of patients, consumers, workers, and the public from unsafe processes and products,” says Engelking. “Yet, among the states that have legalized either medical and/or adult use cannabis, very few measures have been implemented directly involving food safety.”

Cannabis extracts can cause residual biofilms and resins, which are not water soluble, dramatically reducing the efficacy of traditional sanitizer/disinfectant application, says Engelking. “Effective pre-cleaning of these environments to provide contact for sanitizers/disinfectants is paramount in ensuring the performance of routine sanitation.”

As for future issues or problems, the tools and products available for disinfection and prevention in cannabis are limited, because of the federal illegal status of cannabis, notes Engelking. “As this industry approaches parallel regulation with the food industry, traditional audit processes should be used to reassess and direct producers toward building an environment that is able to be routinely and effectively cleaned/disinfected in compliance with modern food processing standards,” she remarks.

Risk is often mitigated in cannabis products that have a baking kill step. However, some cannabis products are comparable to ready-eat-goods (RTE), with no cooking, processing or rinsing required by the consumer prior to consumption, Engelking says. “Left unaddressed, issues throughout the manufacturing and packaging processes and often present themselves in the final cannabis products—making it essential to test final products by lot/batch to ensure continued compliance with clean packaging and processing procedures over time,” she notes.

“We have already seen two cases in the U.S. that positively identified a mortality in connection with mold-borne issues in the medical cannabis supply chain,” says Engelking. “As the industry grows and transparency of processes becomes the norm, expect to see more and more of these types of contaminated products, along with a corresponding increase in consumer complaints and resulting lawsuits.”

For the future, detailed and continuous food safety education, training and certification are essential for growers, distributors, processors, laboratory workers, and dispensary personnel, and should include information about the specific critical control points and potential hazards based on what processes are occurring in each facility, says Engelking.

“We will soon see all cannabis regulations begin to include typical food safety requirements, including: HACCP plans, SOPs, recall plans for both dispensary and manufacturer, general sanitary design and safety requirements, guidance on the use of additives and ingredients, employee hygiene, supply-chain management, remediation techniques and guidance on when to suspend operations due to food safety issues,” says Engelking.

“To assist in meeting these food safety requirements, we will see operators begin to rely more on automated technology related to environmental monitoring and surveillance to assure sanitary practices are effective and being followed,” Engelking concludes.

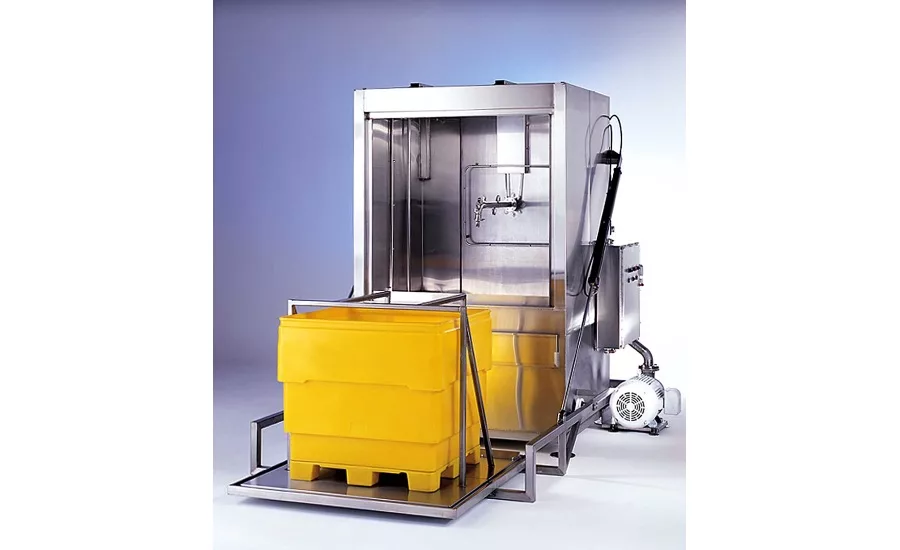

Douglas Machines Corp., Clearwater, FL, has a Clean Out of Place (COP) Parts Washer, which is designed to clean irregular shaped machine parts, small tools, and other types of items such as filters, says Darcel Schouler, marketing manager.

“It’s such a flexible piece of equipment that can adapt to many uses in an effort to eliminate soil, residue, contaminants and foreign matter,” says Schouler. “Our customers have developed some ingenious ways for the COP Parts Washer to solve their washing and cleaning issues,” she comments.

Cannabis edibles and beverages production often involves moving ingredients throughout the facility, involving transport and drying racks, trays, totes and similar containers that require washing and sanitizing, says Schouler. On production lines, washing conveyor belts to eliminate contaminants and debris is a necessity.

“Because cannabis processing produces a large amount of waste product, the large bins (drums, garbage cans and bulk containers) must be washed and sanitized thoroughly to avoid any cross-contamination,” says Schouler.

Douglas Machines Corp. has provided Tunnel Washers, Vat & Bin Washers, Barrel, Drum and Garbage Can Washers, Belt Washers and COP Parts Washers as sanitation solutions to meet the unique challenges of the cannabis Industry.

As for any future issues or problems, the objective for the industry is to stay ahead of the curve when it comes to sanitation and regulation, says Schouler. “Aspire now to meet a higher standard as set forth in the food industry. Federal regulation will create operational standards for the industry. It’s going to happen, sooner or later. Currently, we see irregularities in sanitation procedures across the board, similar to the food industry prior to FSMA. Now is the time for the cannabis industry to focus on reaching for that higher level of food safety regulations and standards. Doing so will allow a seamless integration down the road. Cannabis is such an interesting and rapidly growing industry. We learn as much from our customers as they do from us. It’s a maturation process.”

The future means collaboration amongst a lot of different groups, says Schouler. “For us, it’s about sharing the knowledge accumulated over 40 years of working in the food processing and manufacturing industry and applying it to the cannabis Industry. The excitement for Douglas Machines Corp. is being an early adopter and partner, facilitating improvements and sanitation innovation in the cannabis world. The cannabis industry can benefit from our knowledge and profit from our experience.”