Fortress Technology Adds to Company's Existing Contact Reporter Turnkey Package

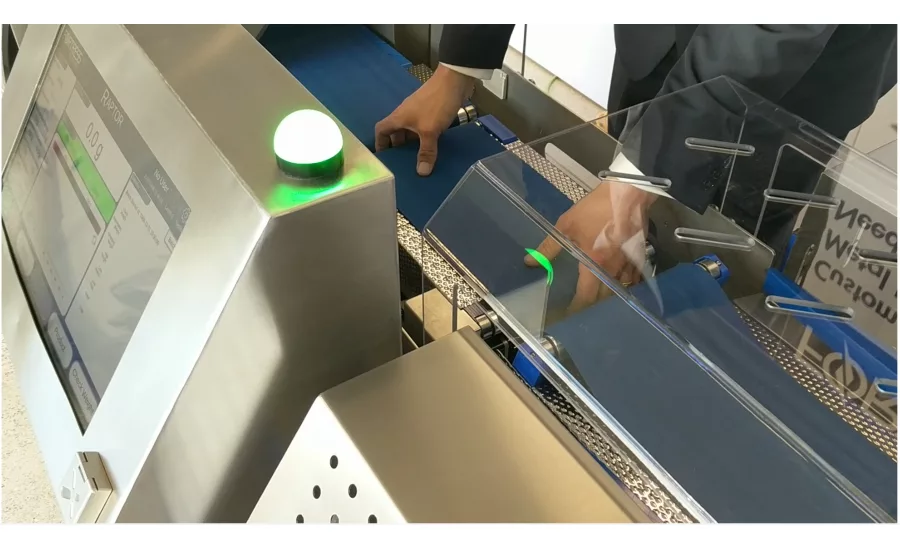

With robust communication the starting point of any good digital transformation program, Fortress Technology has unveiled a new suite of easy to implement industry-compliant data capture and connectivity tools.

Adding to the company’s existing Contact Reporter turnkey package—included as standard on all Stealth and Interceptor metal detector models—global food manufacturers now have the option to automate the collection and collation of data over their network using Contact Manager. Additional options include Contact 4.0 to gather data across a fleet of networked metal detectors as well as Industry 4.0-ready data retrieval communication adapters.

Both Contact Reporter and Contact Manager are designed to assist food manufacturers maintain compliance with all international food safety standards, including Hazard Analysis and Critical Control Points, Brand Reputation through Compliance, and Global Food Safety Initiative/Safe Quality Food.

Contact Reporter provides a robust, easy-to-use event logging and record-keeping solution. Time-stamped data are extracted via USB on a machine-by-machine basis. No complex integration is required. Users simply install Contact Reporter onto their business computer. The software then converts data from the metal detector into readable formats detailing contaminant events ranging from rejects to machine setting changes and test results.

Contact Manager automates data extraction, polling the metal detectors over a secure network connection and generating detailed reports.

Auditor-approved, data reports are exported as either PDF or Excel files covering a specific production line and/or time period. For record keeping, event and performance information is stored securely for a minimum of 10 years, with the option to extend storage capacity to 20+ years.

Fortress Technology | www.fortresstechnology.com

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →