Exclusive interview: West Liberty Foods on high-pressure processing (HPP) technology

Food Safety Strategies was recently able to talk to K. Joseph Swanson, vice president of operations, West Liberty Foods, about high-pressure processing (HPP) technology, and how it has changed over the years.

Liz Parker: How has high-pressure processing (HPP) technology advanced over the past few years?

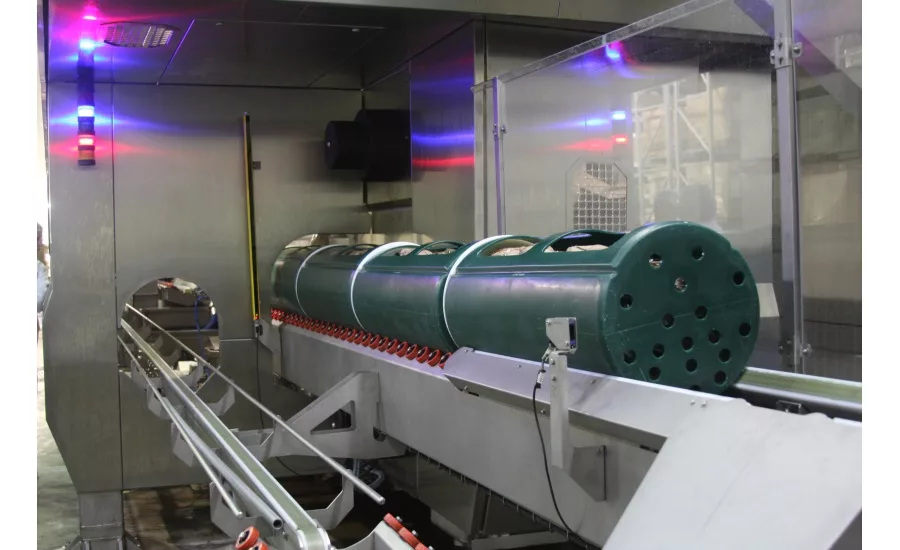

K. Joseph Swanson: The reliability of the equipment has improved significantly over the time West Liberty Foods has used the technology. West Liberty Foods initial unit ran for approximately 100K cycles before the vesel failed resulting in a replacement. Our current models have greatly exceeded this cycle count with no signs of failure.

LP: What are the benefits of using HPP with meat?

KJS: HPP technology reduces the risk of food illnesses and increases the shelf life for our products. Because the technology does not use heat to achieve these benefits, the flavor, color and texture of the products are not affected.

LP: What range of meats can West Liberty Foods treat with HPP?

KJS: West Liberty Foods uses HHP to treat cooked, sliced ready to eat turkey, chicken, beef and pork items.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

LP: Do you treat any non-meat products with HPP?

KJS: West Liberty Foods has also performed HPP services for a beverage manufacturer as a tolling service.

LP: Did you need to update or change your packaging choices when you converted to HPP?

KJS: At the time West Liberty Foods began use of HPP all existing product packaging performed to expectation through the HPP process. West Liberty Foods has included the impact of packaging for retail peel and reseal products that have been developed over the past five years.

LP: Which pathogens does HPP eradicate?

KJS: West Liberty Foods validates our process by ensuring a five log reduction for Listeria monocytogenes. This validation also ensures that other problem pathogens such as salmonella and E Coli are eradicated.

LP: Are there some cases where a combination of HPP and some sort of additional preservatives are required to meet food safety standards? If so, why?

KJS: West Liberty Foods has been able to meet its food safety standards for its products by use of HPP alone.

LP: Are foodservice customers actively looking for cleaner-label meats and other products?

KJS: West Liberty Foods' customers have moved toward cleaner label and fewer ingredient products over the past five years. HPP has enabled these formulation changes to occur while maintain the expected and desired shelf life for the products.

LP: How does your HPP system help preserve energy and water resources?

KJS: HPP is able to lessen the environmental impact of food production by increasing the shelf life of our products thus reducing food waste.