Home » Multimedia » Image Galleries » Slideshow: Improving food safety through blockchain and other traceability technologies

Slideshow: Improving food safety through blockchain and other traceability technologies

Images from the "Improving food safety through blockchain and other traceability technologies" article.

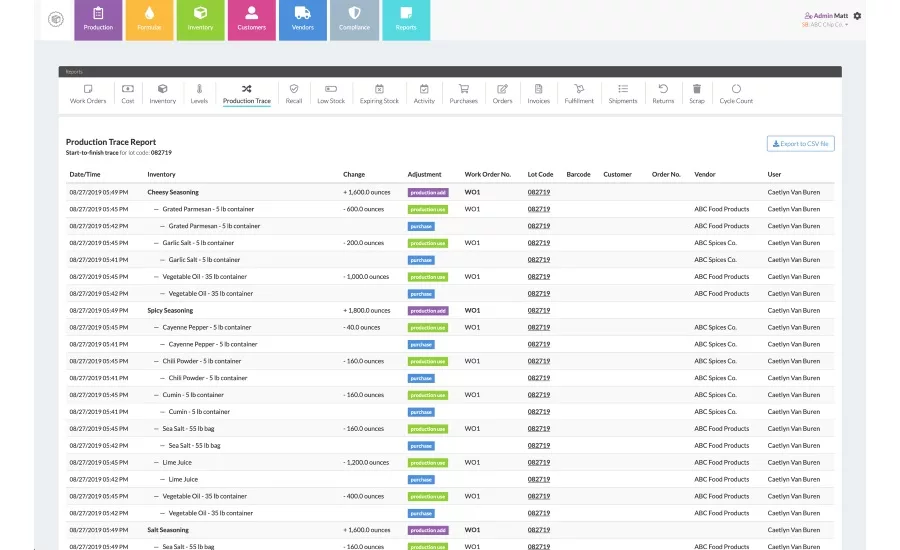

Allocating lot numbers and consuming raw materials while closing production in FlexiBake ERP. Courtesy of: FlexiBake

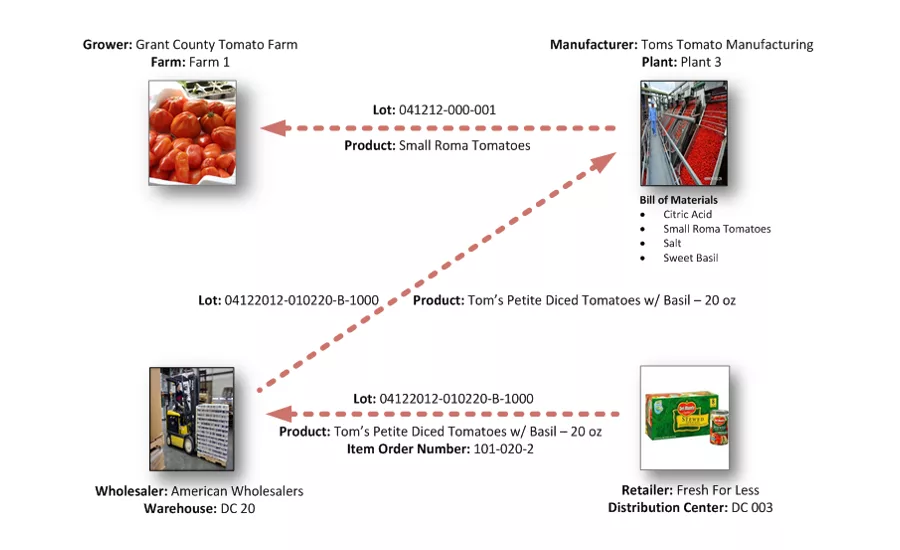

Lot traceability has become paramount for all food and beverage companies, distributor and manufacturer alike. Courtesy of: SYSPRO USA

Lot traceability has become paramount for all food and beverage companies, distributor and manufacturer alike. Courtesy of: SYSPRO USA

As consumers are more interested in product origins and food safety, technology like blockchain could be a gamechanger with the right data foundations. Courtesy of: GS1 US

The TrackEasy solution allows consumers to scan FRISO products using their phone and experience the grass-to-glass journey of the exact product in hand. They can check authenticity, learn more about the the product and its origin. Courtesy of: Kezzler

To ensure that shippers and receivers can view where product shipments are physically, data flows containing details on what is being sent where, by which conveyance and at what time are always one step ahead. Courtesy of: Park City Group

To ensure that shippers and receivers can view where product shipments are physically, data flows containing details on what is being sent where, by which conveyance and at what time are always one step ahead. Courtesy of: Park City Group

Wherefour ERP start-to-finish production trace report for an individual lot code. Courtesy of: Wherefour

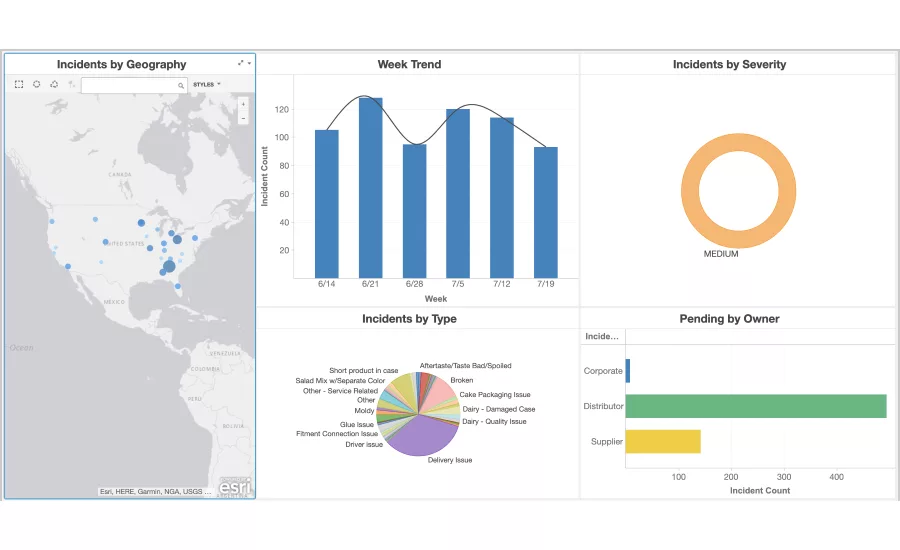

Quality Incident Management—aggregated data shows incident analysis that can be used to address patterns and prevent future food quality and safety issues. Courtesy of: ArrowStream

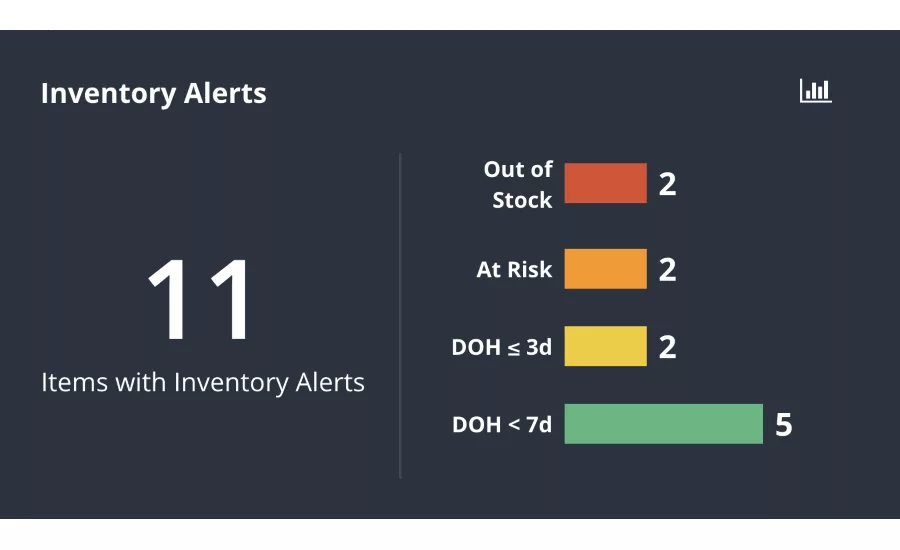

Inventory management Tile—allows operators visibility into their inventory levels and product movement to not only immediately address issues and reduce the impact on their supply chain, but also to prevent future disruptions. Courtesy of: ArrowStream

Olam OFIS technology in use on a Cameroon cocoa farm. Courtesy of: Olam Cocoa

Never miss the latest news and trends driving the food safety industry

Newsletters | Website | eMagazine

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing