FDA Shares Traceback Details for Romaine Lettuce E. coli Outbreak as Investigation Continues

Update: Five Deaths in Romaine Lettuce E. coli Outbreak

Yesterday, the U.S. Food and Drug Administration’s (FDA’s) Voice blog published an update regarding the romaine lettuce E. coli O157:H7 outbreak. The post, authored by FDA Commissioner Scott Gottlieb, M.D., and FDA’s Deputy Commissioner for Foods and Veterinary Medicine Stephen Ostroff, M.D., confirms that any contaminated romaine lettuce from the Yuma, AZ, growing region is no longer available for consumption at this point, eliminating any immediate risk of additional infections.

“Our efforts are complicated by the fact that romaine lettuce is a perishable commodity with a short shelf life of a couple of weeks.”

This means that contaminated lettuce was no longer available by the time the outbreak was identified and the investigation into the source began. Additionally, the lettuce growing and harvesting season in the Yuma growing region was essentially over by the time the outbreak was recognized in April, and harvesting has since ceased. That is why FDA, along with the U.S. Centers for Disease Control and Prevention, have said that there’s no longer any romaine lettuce from the Yuma growing region available for purchase or consumption.

The blog post states that the agency has made progress in recent weeks as they continue to identify the primary source of the outbreak--the largest in the U.S. in more than 10 years. So far, FDA has reported 172 sick people in 32 states. One death has been attributed to the outbreak. Twenty people have developed hemolytic uremic syndrome (HUS), one of the most serious complications that can occur with E. coli O157:H7 infection.

As has been previously reported, health officials say that the outbreak has been linked to chopped romaine lettuce, most of which was consumed at restaurants or purchased at retail. The cluster of illnesses that occurred at an Alaska correctional facility was caused by whole head romaine lettuce, not chopped or bagged like the rest of the outbreak.

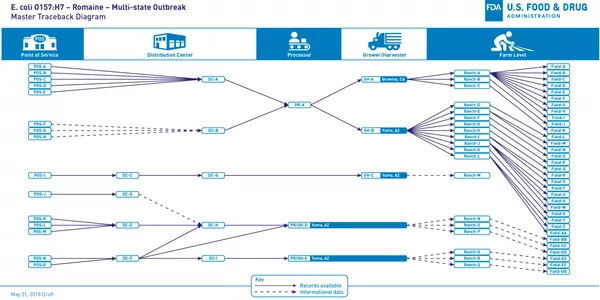

FDA, along with state health officials, have been conducting a traceback investigation that involves working backwards from the point of consumption or purchase of the product through the supply chain. This includes tracing back through suppliers, distributors and processors where the lettuce was chopped and bagged, and then back to the farm or farms that could have grown the lettuce that ended up in those bags. It’s a labor-intensive task, says FDA. It requires collecting and evaluating thousands of records; and trying to accurately reproduce how the contaminated lettuce moved through the food supply chain to grocery stores, restaurants and other locations where it was sold or served to the consumers who became ill. These efforts help to identify common denominators within the various clusters of ill individuals.

FDA’s traceback activities have been documented in a diagram. While it does not include traceback details for all 172 people sickened by the outbreak, it does focus on settings where there were several well-documented clusters of cases. The diagram--which has been redacted and does not include any specific identifying details--will be updated as additional traceback information is received.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

FDA’s diagram shows “no obvious points of convergence along the supply chain. There is only one straight line back to a single farm. And that particular instance involves the whole head lettuce served in the Alaska correctional facility, since it was not processed and was not mixed with lettuce from multiple farms, as seen in other parts of the traceback.”

As for the rest of the diagram, there are no common denominators. Various farms are identified, but no single source. The only commonality within the diagram is that all of the contaminated lettuce did come from the Yuma, AZ, growing region. In all, the diagram indicates that “there isn’t a simple or obvious explanation for how this outbreak occurred within the supply chain,” says FDA. “If the explanation was as simple as a single farm, or a single processor or distributor, we would have already figured that out.”

Because the diagram shows no common distributors, FDA does not believe the contamination occurred near the end of the supply chain. It had to occur “at, or close to, the Yuma growing area.”

FDA says that another possibility is that contamination occurred shortly after the lettuce left the farm.

FDA’s investigation into the source of the outbreak continues. There’s been some speculation about romaine lettuce grown on multiple farms that may have oddly become contaminated around the same time. That is possible when common sources of irrigation water are used, or other environmental factors such as air, dust and animal encroachment are at play.

FDA’s continued investigation includes collaborating with industry experts who may have insights, ideas, or suggestions. This includes working with farmers, technical experts, the lettuce processing industry, state partners, and others. It also includes on-site assessments. FDA is also working with the leafy greens industry and technical experts to explore methods to grow and process lettuce in ways that further reduce the risk of outbreaks.

See the traceback diagram at FDA.gov.

Sign up for Food Safety Magazine’s bi-weekly emails!

Subscribe to our podcast: Food Safety Matters!