PACK EXPO review: Inside the expanding world of packaging at PACK EXPO Las Vegas

Admix promoted its newly patented Rotosolver high-shear mixer. The mixer offers 100 percent wetting out of powders and an easy-to-clean design that meets strict sanitary requirements. The 3-A compliant Rotosolver delivers high intensity, high-speed batch mixing, improved dispersion, and reduced energy consumption for volumes up to 10,000 gallons. The Rotosolver also comes with a process assurance warranty which helps processors confidently test, scale up and go to market faster.

Anritsu debuted its new M6-h metal detector, a dual-frequency, four-algorithm machine with high sensitivity. Built-in digital signal processing brings improvements to isolating product effect and minimizes its impact on detection. Its improved auto-learn process optimizes the best phase, frequency and detection algorithms for the dual simultaneous frequencies, thereby helping manufacturers quickly streamline their inspection and detection operations.

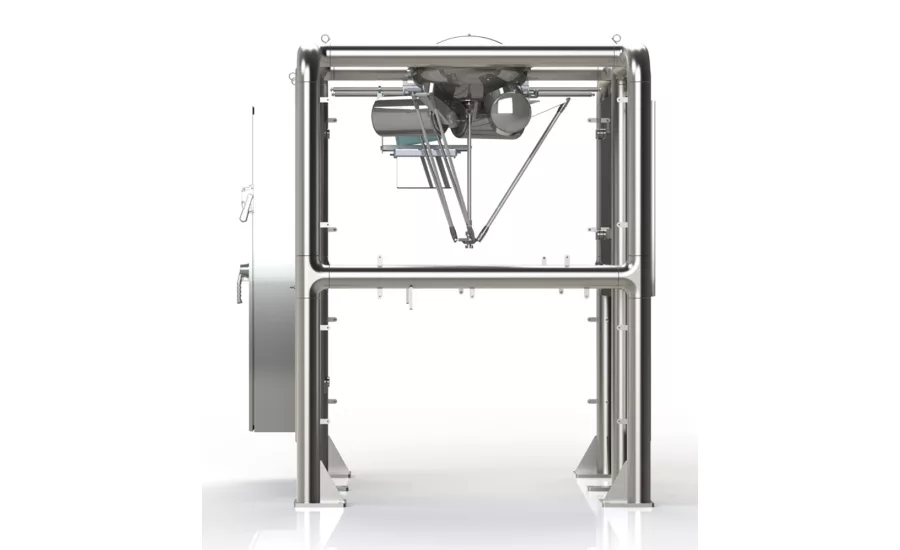

BluePrint Automation (BPA) offers vision-guided robotics solutions, such as sophisticated vision-guided DELTA robots picking individual packaged and unpackaged items for loading into containers or horizontal f/f/s machines, including stacking, wrapper loading, multipack, dinner tray loading and kit assembly. At the show, BPA demonstrated its “pick from a shallow pile” solution designed for bulk products. It uses 2D vision technology to recognize piles and pick them for loading into the required location.

Bosch Packaging Technology introduced new vertical solutions for confectionery, bakery, nut and grain producers: the Yamato multihead weigher ADW-O-0314S and Bosch’s SVE 3220 DZ vertical form, fill and seal (VFFS) machine to safeguard both product and operations, and the Ishida weigher CCW-RVE with Bosch’s SVC 4020 VFFS hygienic bagger to help producers meet diverse food safety regulations. The SVE platform coupled with the Yamato weigher offers high productivity, operational efficiency and format flexibility, including Doy Zip formats up to 320 mm high and 250 mm wide. The machine produces seven bag styles, such as pillow, gusseted, block bottom, corner seal, full corner seal, three-sided seal, as well as Doy and Doy Zip. Changeovers from pillow to Doy Zip take as little as 30 minutes. The SVC 4020 VFFS and the Ishida weigher CCW-RVE let producers meet strict hygienic requirements while addressing individual production standards and demands. Changing pack styles and vacuum belts is quick and requires no tools. Bag style flexibility includes pillow, block bottom, gusseted and corner seal with various reclose and easy opening features in widths of up to 400 mm.

The Bühler Group introduced a new hygienic optical sorting platform, SORTEX F, an optical sorter that provides best-in-class hygienic design and high capacity performance. The sorter is ideally suited to use in the nut and dried fruit processing industry. The machine provides 3-in-1 detection of color defects, as well as shell and foreign materials, for exceptional product quality and food safety. SORTEX F features an accessible and easy-to-clean frame, and its design minimizes the risk of physical and biological contamination.

Bunting Magnetics Co. introduced its NUHI Cartridge Magnet. Completely redesigned from the ground up, the NUHI (neodymium ultra-high intensity) magnet is nearly 20 percent stronger and delivers 25 percent more reach out than the company’s previous cartridge design while delivering more power than competitive cartridges. It has a maximum pull strength of over 105 oz. The NUHI cartridge is built of solid 316 stainless steel and is now standard on the company’s magnetic separation products, including its HF Drawer Filters and Grate Magnets.

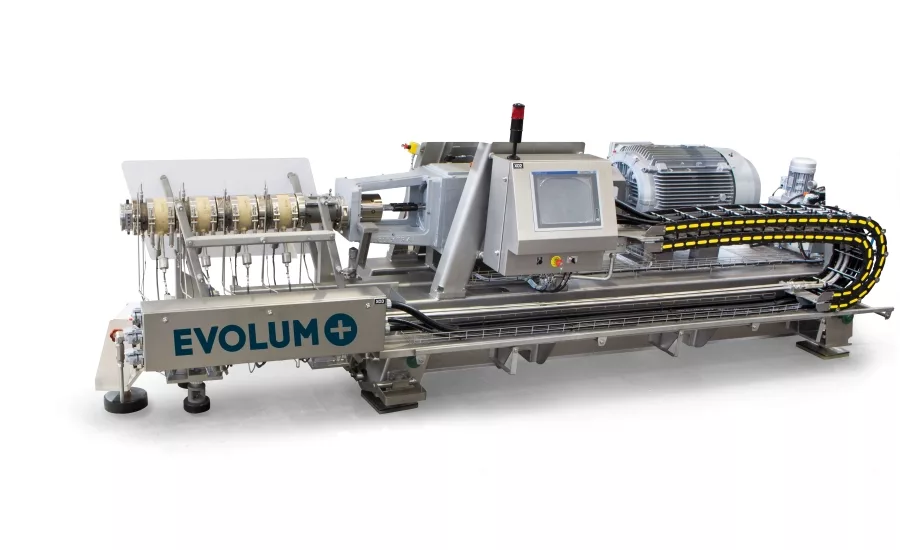

Clextral discussed its ongoing product innovation work using its EVOLUM PLUS twin-screw extruder, particularly conceptual investigations using a wide range of ingredient substrates. The company’s twin-screw extrusion processing lines combine preconditioners, twin screw extruders, dies, formers and dryers to create functional ingredients, encapsulated flavors, textured proteins, vegetarian meat replacements, snacks, breakfast cereals, pasta, couscous, pet foods and more.

Double H Plastics, a manufacturer of plastic and paperboard packaging that services a wide range of food segments, including snacks, cereals and convenience foods, discussed its forthcoming barrier cup, which will offer strength and oxygen resistance. The company uses a unique injection-molding process featuring paperboard inserts and a variety of plastic resins to mold custom packaging solutions, allowing for exceptional graphics and functionality in a wide array of shapes and sizes.

Dow Packaging and Specialty Plastics, a business unit of The Dow Chemical Company, and Nordmeccanica SpA announced the launch of a new lamination technology that features adhesive and machinery hardware advancements. SYMBIEX Solventless Adhesives, Dow’s new ultra-fast curing adhesive technology, combined with the innovative Duplex SL One Shot lamination line from Nordmeccanica, offers converters conversion efficiency improvements, shorter time-to-market and total conversion cost reductions. Other benefits include: the ability to form a package in less than one day from lamination and achieve food compliance within one day for most film structures; reduced line downtime for cleaning; and many more.

Epson America, Inc. introduced the SurePress L-4533AW. Delivering high-quality labels and packaging at a low total cost of ownership, the seven-color inkjet label press is built for short-run label printing with accurate color reproduction on a wide variety of substrates. It has also undergone significant developments to meet the growing demand for fast turnaround, with longer automated printing times, email alerts and minimal maintenance. The L-4533AW offers advanced automated printing features, including up to eight hours of unattended printing. The L-4533AW features versatile substrate support and prints on off-the-shelf materials from 3.15 inches up to 13 inches wide and as thin as 0.00314 inch. The L-4533 also includes processing improvements for variable data processing, such as standard paper to thin films, metallic and laminated pouch materials. The seven-ink digital label press with variable drop size starting at three picoliters also includes a new larger ink drop size, ideal for large solid color backgrounds found on packaging.

Harpak-ULMA announced the introduction of G. Mondini’s new PLATFORMER technology, a combination thermoformer and tray sealer. Combined with the Trave, the new packaging system first forms the tray, then creates a tray seal package. This revolutionary technology cuts the tray footprint before the forming process occurs, reducing scrap to just 1 percent. An additional benefit of this process is that the tray format changeover time is less than 10 minutes with only two components needing to be changed. Packagers have the option of using premade trays or making them inline.

Heat and Control showcased technologies from FastBack, Spray Dynamics, CEIA and Ishida. The FastBack Revolution on Machine Seasoning system combines the FastBack Model 260E-G3 conveyor, the Revolution OMS seasoning system, the AccuFlavor tumble drum and a modular dust collection system into one compact standalone unit. Also on display was the Ishida Atlas iTPS Ultrasonic snack food bagmaker, which offers a reduction in packaging film consumption and improved seal quality using ultrasonic technology.

Hinds-Bock Corp. illustrated the benefits of its new rotary cup fill-and-seal machine. The equipment provides a rugged, safe and sanitary way to accurately fill, seal and lid containers. The rotary cup fill-and-seal machine is ideal for guacamole, hummus, tzatziki, salsa (chunky or smooth), nacho cheese sauce, nut butters, deli salads, and various other sauces and flowable products. Available in two sizes, this new machine can easily integrate into existing production systems or can be custom configured as a turn-key solution.

The newly rebranded Honeywell Intelligrated company showcased its Palmat pallet conveyor, featuring heavy-duty plastic belting with a patented automatic belt take-up system to offer an alternative to rollers and chains for safe and reliable transportation of column-stacked or unitized loads on slip sheets, along with molded or specialty pallets. The company recommends the self-tracking conveyor for applications with fragile or unstable loads, as well as for handling empty containers in preparation for fill lines in food and beverage operations. It’s available with smooth or non-skid belting in single, full-width or multiple strands, supporting operations serving multiple international markets with different load configurations and pallet types. Honeywell Intelligrated featured its Palmat pallet conveyor as part of its robotic palletizing and depalletizing solutions during the show.

JLS Automation showcased its next-generation Talon and Osprey robotic systems. This new hygienic packaging platform for the two systems, featuring a stainless steel robot, integrates motion, logic, safety and HMI into a single scalable platform compatible with full washdown. Talon pick-and-place primary packaging systems are designed to integrate with other packaging machinery, packing trays, clamshells and more, as well as stacking product. The Osprey secondary packaging system has an automatic leak-detection system and can accommodate frequent changeovers. Its small footprint helps it fit into tight locations on the plant floor. End-of-arm tooling (EOAT) can be customized to work with a wide range of products. Talon and Osprey packers are currently used to load a wide variety of bags, pouches, cartons and chub packs, including bagged fresh and frozen bakery like tortillas, flatbreads, muffins, baguettes and snack cakes; cookie dough chubs; wrapped bars; and frozen foods like burritos, corn dogs, egg rolls, pocket sandwiches and pizza.

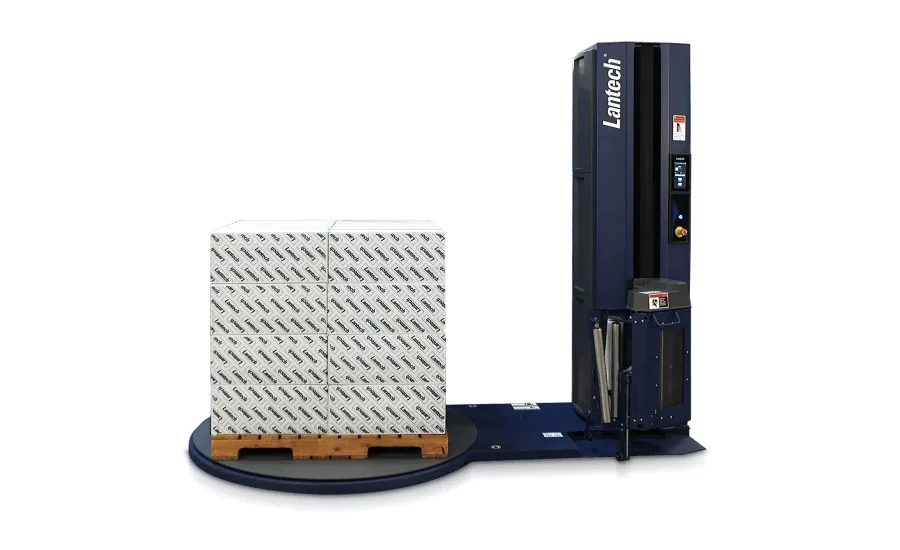

Lantech showed the new QL-400XT Semi-Automatic, an intelligent, intuitive and instructional semi-automatic stretch wrapper. The stretch wrapper allows safe-to-ship wrap profiles to be built quickly and easily for any load configuration. The control guides operators intuitively through the profile setup process with smartphone-like simplicity. The QL-400XT also improves productivity by allowing operators to stay on the forklift. The company also showed its new CI-1000/2000 Case Erector, an easy-to-use machine that fits in a compact footprint and the new CFT6 Containment Force Tool, a handheld device that measures containment force, accurately and easily, at the top, middle and bottom of the load.

Mettler Toledo demonstrated the capabilities of the new C31 checkweighing system, one of the new C-Series checkweighers, gravity-flow metal detection systems that improve monitoring, productivity and operator safety. The C31 StandardLine is highly configurable for standard weighing applications, accepting a weight range of 20 g to 6 kg, with a throughput of up to 200 packs per minute.

The VIBRA-FLEX II® is a unique excited base frame conveyor. This second generation of Meyer’s proven Vibra-Flex vibrating conveyor line incorporates a simple, low maintenance design to provide a high level of reliability, sanitation and operating efficiency.

The VIBRA-FLEX II® utilizes an efficient excited base frame design that delivers consistent sympathetic vibration to the pan through the springs increasing pan life by reducing stress. No heavy structural support is required. The VIBRA-FLEX II® also features all stainless steel construction, allowing for heavy washdowns and an overall sanitary conveying system.

And remember, when you purchase equipment from Meyer, you get our proven record of support after the sale.

• Extremely Simple Drive: The Vibra motor offers a sanitary drive mount with easily adjustable drive forces. This unique drive is maintenance free with no v-belt and no lubrication. The Vibra motor is also extremely quiet at only 0.5 decibels above ambient noises.

• Easy Maintenance: Efficient and robust design with no lubrication required, simple drive design, and long life unidirectional leaf springs provide a high level of reliability.

• Easy Installation: The unique vibrated base frame design offers easy installation and can be mounted on platforms or suspended from overhead. All with no special electrical requirements.

• Super Sanitary Stainless Steel Construction: The all stainless steel construction allows for heavy washdowns and an exceptionally sanitary conveying system.

• Competitively Priced: The VIBRA-FLEX II is not only a heavy-duty, high quality piece of equipment, it is also competitively priced.

• Available in Different Sizes: Specifically designed to fit the needs of your application, these units are available in sizes ranging from 12” to over 6 feet wide.

Vibra-Flex II®

The Meyer VFII line of Vibratory Conveyors offer sanitary and low maintenance conveying solutions. Available with adjustable drives and interchangeable inserts, VFII conveyors are ideal for a variety of conveying applications including screening, dewatering, laning, grading, feeding and spreading processes while conveying of your in-line bulk material handling processing needs. There are two models featured at Pack Expo this year; one with a Scale Feeder and one is a Dewatering Vibratory Conveyor. Additionally, KOFAB, manufacturer of the Curveyor and sister company to Meyer Industries, was in Pack Expo for the first time.

Nercon announced the launch of its Washdown Spiral, designed specifically with sanitation in mind. Sanitary Design Features include: open construction for readily accessible cleaning, inspection and maintenance; corrosion-resistant stainless steel construction and plastic belt; CIP design with open belt surface for easy washdown from any angle; self-draining, bent frame construction to eliminate water pooling; solid UHMW guide rails; and the ability to withstand up to 1,500 psi washdown pressure. The spiral’s edge-driven design includes sprockets that drive the chain in multiple locations, which distributes the force across the entire length of the chain, not from just one location. This allows for higher construction elevation, reduced belt tension for longer belt life and increased load-carrying capacity.

Process Sensors Corp. exhibited its snack food stainless steel process analyzer, QuikCheck benchtop analyzer, and IR temperature and thermal imaging systems. The company’s Guardian System can measure coatings on the wet or dry end, or it can also be employed to measure dryer exit moisture and the re-moisturizing operation, providing ultimate flexibility. All systems feature analog outputs and digital communications. The MCT466-SF for process food moisture and oil/fat measurements is enclosed in a stainless-steel housing suitable for washdown environments. The at-line or laboratory QuikCheck provides fast sample turnaround and reliable moisture and oil measurements. Non-contact thermal imaging cameras and temperature sensors are also available to determine dryer/baking characteristics for cookies, crackers and other products correlating to the dryer temperature gradient.

Reiser featured live demonstrations of its complete line of food packaging equipment and processing-to-packaging solutions. The company showcased lines of Ross tray seal equipment, Repak f/f/s packaging machines, Supervac vacuum chamber packaging machines and Fabbri automatic stretch wrappers. Reiser offers all lines in a variety of model sizes to meet virtually any production requirements, allowing customers to choose the best packaging solution for their application. Industries served in snack and bakery by Reiser equipment and solutions include bread, rolls, buns, English muffins, pizza dough, cookies, bars and brownies.

Schubert North America demonstrated the flexibility of its high-performance technology by means of a picker line with an integrated Flowmodul—a new compact flow-wrapping component. The Flowmodul allows food and confectionery products to be packaged in flowpacks in a highly flexible and space-saving manner. With the Flowmodul, image recognition for quality control, pick-and-place robots and packaging in flowpacks all come together in a compact and versatile system. A single control module operates the entire system. The innovative packaging technology achieves record-level performance in packaging a wide range of products in terms of space requirements, conversion times and product variety.

As part of its presence at PACK EXPO Las Vegas, Siemens demonstrated the capabilities of its “Digital Twin” manufacturing simulator—a transformative digital approach toward streamlining production before it begins. Within the context of food production, a Digital Twin is a digital model that accurately represents a given process on the line. Whenever another component or process is added or subtracted from the line, the Digital Twin automatically updates to reflect those changes, providing instant feedback. This process helps food manufacturers develop supremely efficient and error-free lines before actual implementation while notably improving speed to market. The approach can help producers design to meet the demands of any number of variables, including cost and regulatory compliance. The company also notes that it becomes a model for continuous improvement and innovation. Siemens welcomes snack producers and bakery companies to witness the power of the Digital Twin firsthand.

Soft Robotics, known for its new class of robotic grippers, announced the release of its expanded and upgraded Soft Robotics Development Kit, SRDK 2.0, featuring: robot tool flange mounting plate; four, five and six position hub plates; tool center point; Soft Robotics Control Unit G2; six rail-mounted, four accordion actuator modules; custom pneumatic manifold; and mounting hardware and accessories. During the show, Soft Robotics demonstrated its unstructured bin picking capabilities with human supervisory control. The system setup enables rapid training of the picking process, with the robot progressively learning as the picking process progresses, and application-specific end-of-arm tooling (EOAT) is available.

Somic America featured a variety of packaging samples created by its 424 T2 (D) multi-purpose, retail-ready case packer. The machine delivers high performance by collating, grouping and packaging products in open display trays, as well as trays with covers and wraparound cases. It also can be fitted with individual format tools for a wide range of product dimensions. The 424 T2 (D) is capable of collating 600 products per minute depending on size, and can carton as many as 35 cases per minute. The case packer can place products in any orientation, and many label-facing orientations are possible.

Stäubli showcased its new TX2 line of collaborative robots, simulating a highly realistic “smart factory” with different TX2 models in multiple interlinked cells, demonstrating their Industry 4.0 compatibility and collaborative skills. The new TX2 line is offered in six model series: TX2-40, TX2-60, TX2-60L, TX2-90, TX2-90L and TX2–90XL, and is capable of handling loads between two and up to 15 kg with a reach between 515 and 1,450 mm. The six-axis robots have a separate safe digital encoder for each axis and an integrated safety board. All safety features comply with the stringent requirements of the highest safety category, SIL3/PLe. Stäubli robots are used to help automate a wide range of operational tasks across the food industry, including cutting, slicing, pick and place, handling trays, palletization, mold form, decoration, adding ingredients and more.

The new Sentinel multiscan metal detector from Thermo Fisher Scientific rapidly scans up to five frequencies to help food manufacturers find ferrous, non-ferrous and stainless steel metal contaminants in products—including those up to 70 percent smaller in volume than previous technologies. Inspecting select types of products, including bread, for foreign objects is especially challenging because signals from a particular type of metal can be hidden inside the electromagnetic response of the product. With prior technology, switching the operating frequency could make the hidden metal detectable, but could then make a different type of metal undetectable. Thermo Fisher designed the Sentinel to alleviate this problem by scanning multiple frequencies. Because the Sentinel metal detector has the same footprint and aperture location as the APEX 500 metal detector, users seeking to upgrade to the new platform can easily do so.

At PACK EXPO Las Vegas, tna unveiled a new, fully automatic closed loop slurry mixing and spraying system that delivers advanced levels of application consistency and accuracy. The new tna intelli-flav CLS 5 was specifically designed to accurately and efficiently blend and apply slurry seasoning to a range of extruded and dry snack products. Featuring a single tank and up to six precision spray nozzles, the tna intelli-flav CLS 5 continuously monitors the under-surface mixing of the oil and seasoning powder to deliver a homogenous mix for a consistently flavored, high-quality product with reduced slurry or product waste. The system has four different spray lance design options and a compact, single tank design with a low volume reservoir (50l/13gal) that ensures there is minimal waste during the frequent flavor changes of short production runs, but is equally suited for high-volume throughput levels. During the show, tna also presented its ultra-high speed case packer for flexible bags, the tna ropac 5, capable of up to 300 bags per minute.

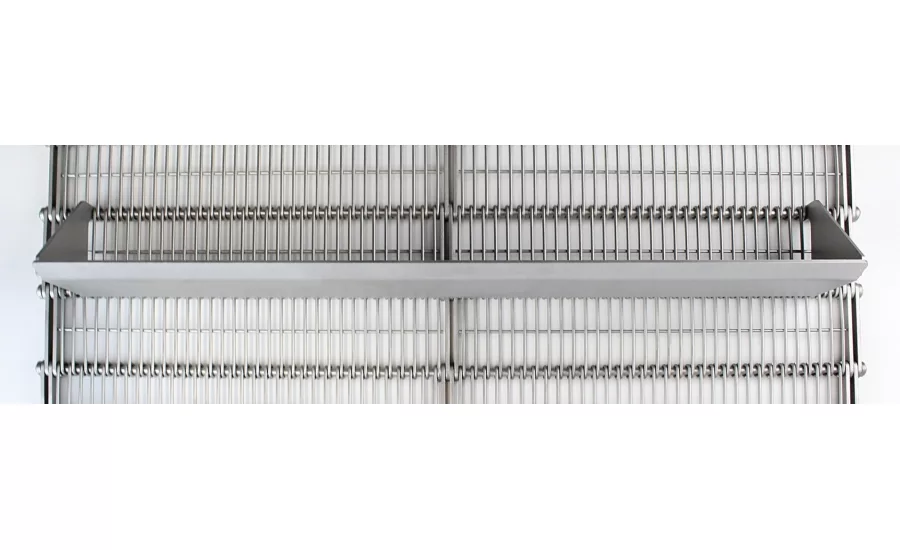

Wire Belt Company of America is now offering stainless steel flights for its Compact-Grid conveyor belt. The flights offer a stainless-steel option (instead of plastic) to snack and bakery producers seeking an inclined conveyor orientation. The flights, secured via multiple fasteners, can accommodate a wide range of products and are easy to clean.

Yale Materials Handling Corp. demonstrated its robotic end rider lift truck with Driven by Balyo technology. The MPE080-VG robotic lift truck automates repetitive load transportation tasks to improve productivity. It picks up, transports and drops off pallets anywhere on the floor using infrastructure-free navigation technology to map and guide itself by recognizing existing structural features. It can also switch to manual mode with the touch of a button. Yale also offers two other robotic lift truck models with Driven by Balyo technology: the MO70T tow tractor and the MC10-15 counterbalanced stacker.

PACK EXPO Las Vegas took place at the Las Vegas Convention Center September 25–27. PACK EXPO, North America’s largest packaging trade show in 2017, is presented by PMMI, The Association for Packaging and Processing Technologies.

PACK EXPO Las Vegas attracted 29,500 attendees, including food industry executives, engineers, plant managers, research and development staff, brand and marketing managers, quality control professionals, purchasers, and packaging designers. This was the largest PACK EXPO in history.

The event offered attendees the opportunity to connect with 2,000 exhibitors showcasing the latest packaging equipment and technologies, with solutions for markets across the food industry, including snack and bakery (see the slideshow on this page for a survey of packaging equipment, materials, technology and more now available to help grow your snack food and bakery business).

The event also included a range of education opportunities presented on the show floor, as well as specific pavilions, including The Containers and Materials Pavilion, The Confectionery Pavilion, and The Reusable Packaging Pavilion. The Dow Chemical Co. again sponsored the “Showcase of Packaging Innovations” on the show floor, highlighting the latest innovations and award-winning packaging designs from around the world.

As part of the PACK EXPO Innovations Stage educational presentations, Elizabeth Avery, CEO, and David Walsh, vice president of membership and communications, both of SNAC International, delivered a session on “U.S. Snack Industry: Emerging Snacking Trends and Regulatory Issues Shaping the Market.” The session showed how the current shift in consumer lifestyles has led to an increase in snacking, illustrating how to explore new opportunities to reach consumers via traditional and new and emerging snack categories. The session also touched on valuable insights related to key federal and state regulatory issues impacting the snack industry.

On the first day of PACK EXPO Las Vegas, PMMI released its 2017 “State of the Packaging Industry” report. In the report, PMMI forecasts of strong growth in the U.S. packaging industry, with a 4.8 percent increase in the U.S. packaging machinery market from 2015 to 2016, coming in with a total market value of $9.8 billion.

The next generation of supply-chain logistics includes guided and autonomous technologies like drones. PACK EXPO attendees were permitted a look at advances in drone technology at the PACK EXPO Drone Demo, “Packaging for the Last Mile.” The display featured a virtual landscape, including mailboxes and doorsteps to accept delivered packages. Delivery drones launched from the top of a stationary delivery van and made deliveries to the mock houses, while screens showed the drone’s perspective via live video from cameras mounted on the drones.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

The PACK gives BACK concert, with a performance by the Doobie Brothers, produced the largest crowd to date in the event’s seven-year history. Proceeds from the performance, combined with industry donations and PMMI’s $100,000 match, pushed the donation total past $325,000, which went to hurricane aid.

PMMI also awarded $30,000 of PACK EXPO Scholarships. The PACK EXPO scholarship program supports the future packaging and processing workforce. Six students studying packaging and processing at PMMI Partner Schools were each awarded a $5,000 scholarship.

PACK EXPO International will take place October 14–17, 2018 at McCormick Place in Chicago.

This article was originally posted on www.snackandbakery.com.