Engineering R&D

Supply chain solution includes sensors, digital visibility platform, cloud access

Cloudleaf puts the supply chain pieces together to connect data silos

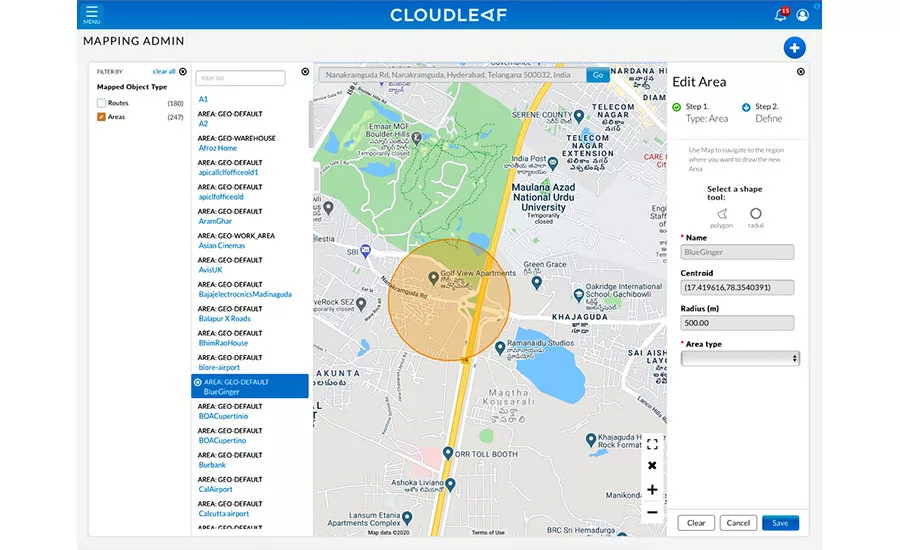

Cloudleaf’s Digital Visibility Platform can narrow down a shipment anywhere in the world while reporting key data, such as temperature, humidity and time/mode in transit.

Image courtesy of Cloudleaf

The COVID-19 pandemic has provided a stress test for supply chains everywhere and has revealed several weak spots in food and beverage, especially in the pork, poultry and beef markets—with farmers stranded with animals they couldn’t send to the slaughterhouse and shortages of these protein products at retail outlets.

One problem is there are many supply chains with siloed, incompatible data, not to mention supply chain participants still using clipboards and manual data entry. Those that have software systems find their system doesn’t work with others, and these cobbled-together systems are anything but real-time. Hardware support isn’t any more standardized.

Enter Cloudleaf, a company founded in Silicon Valley six years ago to take a new approach to unlocking the massive, untapped value hidden within supply chains—and transforming them into more powerful, data-driven strategic assets. Its key product, the cloud-based Supply Chain Digital Visibility Platform, provides complete, real-time views and insights from suppliers to production, distribution and customers, making it possible to intervene to improve supply chain efficiency before an issue results in a fine or profit loss.

To learn more about Cloudleaf’s supply chain solution, I spoke with Mahesh Veerina, president and CEO, who has more than 25 years of experience in high-tech companies, including Nokia, Motorola and Ramp Networks.

FE: How and why did you start Cloudleaf? What was your vision?

Mahesh Veerina: Cloudleaf was founded on one simple idea. The idea that the power of data—from a tiny sensor to track time stamp, location, condition, quantity and context of a product’s journey across the supply chain in real time—will profoundly transform the future of supply chains.

Our vision is to power the next generation digital supply chains with continuous visibility and intelligence, to transform supply chains into data-driven strategic assets for enterprises.

FE: You have supply chain solutions for several industries, including pharma. What were the challenges in developing a supply chain solution for our industry?

Veerina: Pharma and food and beverage share many of the same challenges: transporting sensitive, highly perishable goods, and ensuring product quality and integrity is paramount in both industries. Having visibility into factors around condition, timing and location help create a real-time view into what’s happening at every point along the supply chain.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

Temperature, humidity, light and vibration excursions can happen anywhere along the supply chain and result in serious illness and loss of life if food is spoiled along the way. We’ve solved one of the biggest challenges—capturing product-level data, not just information about the truck or container the product is on, which is an incomplete picture. We take that product-level knowledge and integrate it with other contextual data bringing formerly siloed information together for a real-time view of what’s happening on the ground as goods move along their journey through the supply chain. For instance, we worked with a poultry manufacturer to digitize the journey from farm to hatchery, which significantly decreased chick morbidity.

FE: How does Cloudleaf’s solution work?

Veerina: Cloudleaf’s system is an interoperable horizontal platform that is able to integrate with any legacy systems our clients are already using. Sophisticated sensor technology makes it possible to collect more kinds of data than has previously been accounted for. That data is fed up to the cloud and into our platform where client teams remotely track materials and goods. This enables visibility at the product level—the package, pallet or product container going beyond simply tracking the truck or plane or ship that transport your products, which is essential when you are shipping perishable foods and beverages.

The system also sends alerts when conditions along the supply chain are changing and at risk as a result. These alerts are so precise that they potentially provide enough notice for intervention by whichever vendor has the product at the time, depending on the vendor’s own operations.

FE: What technology does Cloudleaf use?

Veerina: Cloudleaf's Digital Visibility Platform applies a combination of IoT, AI/ML and cloud computing to gather, integrate and analyze data to then generate the scenario of conditions on the ground for use cases, such as asset tracking, cold chain management and condition monitoring.

We’ve taken a holistic approach to supply visibility by looking at sensor-driven hard attributes, such as time stamp, location, condition, and count and contextual attributes, such as business processes, enterprise systems, 3PL, weather and planes.

FE: What hardware is required?

Veerina: One of our differentiators is that our Digital Visibility platform is device agnostic. Cloudleaf Sensor Fabric ingests and harmonizes the multiple data streams and is the connection point for visibility into a supply chain. An intelligent network made up of IoT sensors and gateways collects unique location, condition and flow data, continuously delivering information to the cloud. Sensor Fabric software works with existing sensors, third-party devices and Cloudleaf’s own patented sensor technology. Cloudleaf’s sensors have three to five years of battery life, which allow assets to be tracked indoors and in-transit for operations of all sizes.

FE: Do all supply chain participants need to purchase your system and hardware?

Veerina: No, our platform can ingest multiple device and data streams from across the source-make-deliver spectrum. For instance, FlightAware is integrated so a customer can monitor a shipment while in the air and be alerted if there is a delay.

FE: How do you accommodate those supply chain members still using manual systems?

Veerina: Digital transformation is a journey that often begins with one project to prove out the value of digitizing a process. For example, with more than 100,000 mobile and fixed tools used within the manufacturing process, a global appliance maker needed to replace a manual inventory and tracking process that was costing it millions of dollars annually in write-offs. Implementing Cloudleaf to monitor critical tools in real time provided 100% visibility into the location and condition of the assets, saving millions of dollars and significantly improving production. So I would urge supply chain leaders to look at the low-hanging fruit first.

FE: What if a supply chain member is using SAP or another system—how do you connect?

Veerina: Our API-based platform supports more than 400 APIs to connect to any sensor or new IoT device, and is simple to integrate with and enhance legacy ERP systems. It’s easy and fast to install.

For more information, www.cloudleaf.com