New food inspection equipment offers greater performance and cost savings

From flying cars to sustainable energy sources, visions of tomorrow’s most life-enhancing technologies invariably revolve around more efficient ways to operate. Although some of these solutions lie in a more distant reality, manufacturing’s pioneers have shaped cutting-edge forms of product inspection technology that help processors make significant gains in food safety while enhancing efficiency. These recent strides also have manufacturers focusing on cost in alignment with capability—and niche automation markets, such as machine vision, are expected to grow even more. According to the 2018 State of the Industry US Packaging Machinery Report produced by PMMI, the Association for Packaging and Processing Technologies, the Inspecting, Detecting and Checkweighing Machinery category is projected to expand from $438 million in 2017, experiencing an 8.6 percent annual growth.

Where accuracy meets speed in vision systems

Today’s food manufacturers must inspect every item on their processing line. Older protocols may have only required checking for proper label adherence, providing a “yes or no” answer. Now, detection solutions deliver more than a just single piece of a complex puzzle. Vision systems provide more comprehensive and precise observations—checking that the right label is on at the right level, assuring that the bottle is not broken or chipped and is filled to the right level, etc.

All together, investment in new inspection equipment that can detect multiple types of anomalies with greater precision and speed invites opportunities for cost savings. Firstly, processors stand to reduce the waste that accumulates from defective product. Secondly, they are minimizing the downtime that stems from stoppages and fixes required in the event of a malfunction or missed inconsistent output, maximizing return on investment (ROI). Last, but not least, the company avoids a potential recall and a devastating hit to its brand reputation.

Improved HMI and data analysis eases operations

Smart design isn’t simply limited to the mechanics of today’s vision inspection equipment. The Human-Machine Interface (HMI) has also improved to offer more intuitive operator capability. This technology does not require extensive training of a skilled worker, which translates in shorter training and higher productivity. For example, operators with limited training can operate machines and transition to different formulations or packaging formats. Menu options make it easy for operators to select programs, which enable swift changeovers.

The value of HMIs is not limited to what you see; it’s also found in the consistency and expediency of data collection and analysis, in many cases able to integrate data from legacy equipment on the same line. Today’s solutions help processors to store and display key performance indicators that are essential to making strides in food safety and meeting increasingly regulations set by the Food and Drug Administration (FDA) and other agencies.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

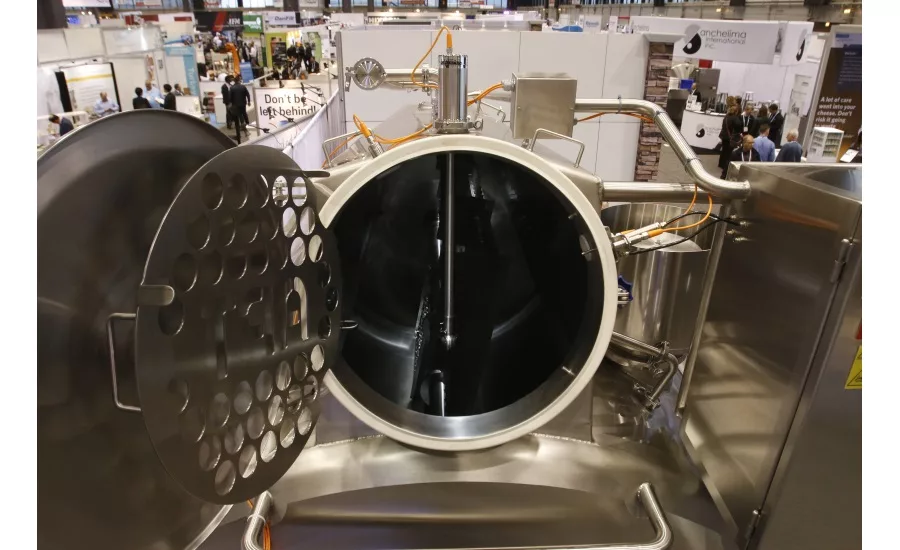

X-ray technology evolves

From its origins in detecting foreign materials in products, such as glass, metal and plastic, x-ray technology has come a long way. The inspection equipment has become more sensitive and is able to deliver more breadth of information; from examining the shape and edges of a food product to telling you its density and volume. X-ray technology no longer just detects a foreign piece of material, it provides detailed information about the product.

In addition, manufacturers have increased the sensitivity of the detectors. In the past, the power necessary to operate the equipment required cooling during its operation. Now that the power is pointedly less, there is no need for cooling and health risks have also been reduced significantly, while also consuming less energy during usage. Due to the sensitivity of the detectors, there’s an abundance of new information to garner that can help companies build protocols for efficiency into their operations.