Maintaining safe and sanitary meat and poultry processing with certified conveyor

The long-term impact of COVID-19 is unclear, but for now the outbreak has impacted the food industry in a myriad of ways. For meat and poultry processors, there have been significant changes, not only to how consumers buy their food, but also to the way produce is processed and distributed. Hygiene remains a top priority, including the conveying of fresh and processed meat, which marks a critical point in the process to control safety and sanitation.

Despite no reported cases of the virus transmitted by food or food packaging, the USDA highlights the necessity to follow good hygiene practices when handling or preparing foods to protect both the workforce and the consumer. More recently, the US has been rattled with meat plant closures to contain the spread of the virus.

For the meat plants that remain open, regimented hygiene, cleaning and testing programs are essential to prevent the build-up of pathogens and allergens in the processing environment at this unprecedented time. This is particularly true for enclosed conveying systems, where smart design, expert construction and new technologies are integral to maintain the highest hygiene standards and prevent dangerous and costly recalls.

Recalls on the rise

Long before the outbreak, hygiene and sanitation remained top of the agenda for protein manufacturers. A number of factors including industrial farming methods and more complex supply chains have led to a sharp increase in high-profile contamination cases, proving an expensive and serious health risk for consumers and manufacturers alike.

A report from Public Interest Research Group (PIRG) shows that recall cases in the US increased by 10 percent between 2013 and 2018,[1] hitting a peak of 905 in 2016, with undeclared allergens and bacterial contamination noted as the leading causes of withdrawals within the sector.

In 2018, just over 13 million pounds of ground beef alone were recalled in 31 separate instances, more than 12 million pounds of which were due to salmonella contamination.[2] More recently, the Center for Disease and Control released a statement reporting that eight people had been hospitalized and one had died due to an outbreak of salmonella in ground beef.[3]

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →

Regarding chicken meat, the US accounts for roughly one third of all poultry exports globally, meaning understanding factors that can cause poultry-associated foodborne outbreaks has huge implications for food safety. There have been dozens of recent cases in the media, including the withdrawal of 174,000 pounds of chicken products for possible contamination with listeria.[4]

To avoid costly recalls, a robust preventative strategy is paramount. The implementation of the FDA’s Hazard Analysis and Risk-based Preventive Control (HARPC) act has transformed food processing by shifting the focus from responding to contamination to preventing potential hazards from occurring. Which is why hygiene and sanitation is the primary concern for meat and poultry manufacturers using automated conveying systems.

Protect your protein with USDA-accepted tubular chain conveyor

While no company can completely eliminate the risk of contamination, following best safety practices can help minimize the possibility. Manufacturers have a responsibility to establish a food safety plan to comply with legal requirements, with contaminant management being an integrated part of the program.

The USDA regularly updates its controls guide to outline hazards generally recognized and associated with meat and poultry products and how to avoid these.[5] Concurrently, it is also important that adherence to hygiene and safety standards does not adversely affect the product quality and efficiency of a factory line.

When specifying conveyors, suppliers must consider higher frequency of cleaning with the use of chemical sterilization. Enclosed tubular systems are beneficial in keeping the product protected from atmospheric, airborne contaminants and other bacterial elements introduced by people or other meat and poultry products. By maintaining a safe and hygienic processing system all the way to the packaging line, the risk of product recall is significantly reduced.

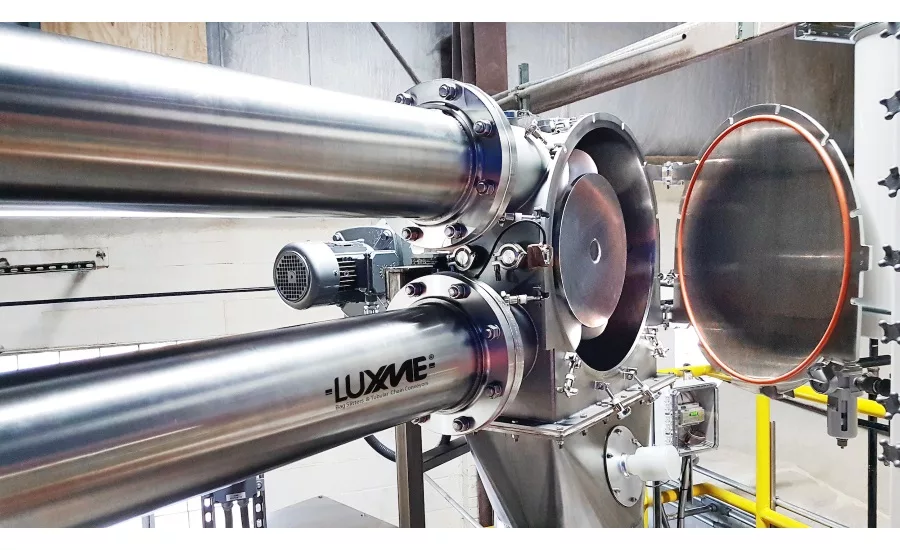

Clean-in-place (CIP) technology is also advantageous, as it avoids the dismantling and reassembly of the equipment and provides a re-usable, sanitized conveyor within a significantly shorter period. For example, Luxme International’s Tubular Chain Conveyor can be totally cleaned and sanitized in just 60 minutes from dry to dry, substantially slashing cleaning time and allowing for a 20-25 percent increase in productivity. This is made possible by the CIP SaniLux technology, a completely independent system that is isolated from the upstream or downstream equipment in the process line and is interlocked for operation and safety with the feeding and recovery equipment.

The conveyor system itself comprises a fixed drive and tension assembly, which automatically tensions the chain continuously during the process and regulates it according to friction, product flow and variation in atmospheric/product temperature. Furthermore, it is believed to be the only USDA-accepted solution for transporting meat and poultry using this specific method, meeting the most up-to-date and stringent guidelines set out by the US federal executive department.

USDA-accepted systems with FDA-approved components will ensure a high standard in terms of hygienic design, incorporating approved food-grade materials that allow for optimum function and sanitization. In addition to providing manufacturers peace of mind that their system is microbiologically clean, machinery designed to a recognized standard typically requires less cleaning time, saving on water, product, labor costs and energy.

Despite only comprising one step in a meat and poultry manufacturer’s much larger and intricate manufacturing line, conveying is a significant part of the process. What lays ahead for the industry is yet to be seen, but machinery that maintains productivity without compromising hygiene and safety is essential if a supplier is to overcome any emerging challenges.