Delivering on the Promise of the Paperless Lab

Organizations have made significant investments in enterprise and laboratory tools, technologies and solutions to help improve productivity, better manage data/information and optimize their business processes. However, the reality is that most companies have not reaped the return on investment (ROI) or efficiency gains that they planned. This article demonstrates how the Paperless Lab can improve efficiency, compliance and quality by integrating data silos and automating laboratory operations.

What is a Paperless Lab?

What is a Paperless Lab?

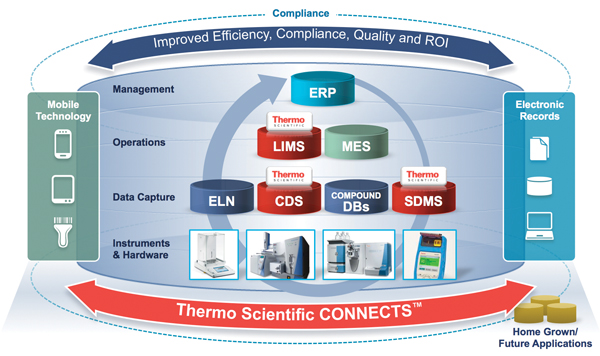

A Paperless Lab integrates the laboratory with the enterprise and automates systems by eliminating paper-based, manual and error-prone processes. While most companies have invested in many instruments and software solutions in the laboratory, manufacturing and the enterprise to improve operations, these systems are not seamlessly integrated, creating data silos, or standalone information repositories that do not communicate with one another. By automating operations and integrating these individual solutions, organizations can reduce paperwork, increase efficiency and throughput, automate regulatory compliance, reduce costs, foster collaboration and make faster, better-informed business decisions (Figure 1).

What’s Wrong with Paper?

The benefits of using paper are evident. It’s easy to use, convenient, portable and legally defensible; and, it requires little (or no) user training and supports multiple data types. Unfortunately, paper also has some major drawbacks. It introduces security risks, it’s expensive, it’s not searchable, it’s not collaborative, there are significant storage issues and, perhaps most importantly, it’s error prone and susceptible to transcription mistakes. In any process, the handling of paper is usually a manual (human) activity. Additionally, manual activity is inherently prone to errors. At the very best, for every 1,000 results transcribed from an instrument, the human will make, on average, 3–6 mistakes. Typical error rates increase to three per 100 transcribed results (or 30 errors for every 1,000 results) if any math or stress is involved. In addition, large volumes of paper-based data are difficult to store and practically impossible to search later.

Just How Costly are Manual Errors?

Just How Costly are Manual Errors?

Imagine, for example, that you have seven people in your lab spending 20% of their time annually writing documents. This involves documenting lab tasks (writing docs to communicate results or reviewing documentation), and every one of these activities must be logged and, in some cases, approved by another person. Imagine if you could reduce those efforts by 10% -- this translates to putting 336 hours, or 42 days, back into doing more productive and meaningful work. If you could reduce those same efforts by 20%, you could create 672 hours (84 days) and earn cost savings of $154K per year (Figure 2).

Imagine what you could do if you reduced the amount of time your employees spend manually collating reports, preparing samples, performing calculations, etc. What could your company do with savings potential like this? Your scientists and lab personnel will be able to spend more time on value-added activities that generate revenue.

Why are Customers Looking for a Paperless Lab Now?

None of this is new information. Companies have always recognized the potential benefit of integration across the enterprise, but they’ve been too busy focusing on other priorities. It wasn’t until recently, in a continuing effort to reduce costs, that companies have turned their attention to automating laboratory processes and/or instrumentation and integrating that data with existing enterprise resource planning, laboratory information management and electronic laboratory notebook systems, among others.

The problem is that these tools and technologies are, if left unconnected, accessed separately, creating islands of information. Compiling data from multiple systems is laborious, and users will often resort to spreadsheets in order to access the data they need. Data are disaggregated across the organization, both internally (R&D, manufacturing, geographic, functionally, etc.) and externally (contract companies, suppliers, research institutes, etc.). To exacerbate the problem, new solutions (tablets and mobile devices) further complicate the integration issue.

Keeping these systems separated fails to maximize your investment and introduces unnecessary inefficiencies and errors. In addition to not achieving expected ROI, you may not be able to find the information you need or view your data in a way that enables fast and informed decisions. What is the result? Companies are left with significant exposure, from compromised product quality to delayed decision making to releasing bad products into the market.

How Should You Select a Paperless Lab Solution?

As you consider your options for creating a tightly integrated paperless lab, look for an offering that combines a solid methodology for analyzing your existing workflows, state of the art technology to move your lab operations to optimum efficiency, and comprehensive services to implement the Paperless Lab and support your company’s ongoing needs.

Implementing any solution should begin with a methodology—a comprehensive consultation to assess your organization’s existing laboratory automation, instrument integration and workflow. The assessment should highlight potential ROI and operational gains and deliver a plan for addressing where current workflow relies on human intervention (often the cause of bottlenecks or errors).

On the technology front, the offering you select should leverage your organization’s existing investments, even if they’ve been purchased from a variety of commercial vendors. The ideal solution should integrate instruments and equipment, connecting data sources with data destinations via a single interface. State of the art integration middleware can translate disparate instrument languages and convert raw data to a vendor-neutral storage format for data archiving. Finally, in keeping pace with technology advancements in and out of the laboratory environment, your investment in a paperless lab solution should be able to offer access to raw data and instruments from any web browser or mobile device.

Last but not least, your solution provider should offer pre- and post-implementation consultative services to ensure the paperless environment is continuously optimized as the lab environment changes or as your business needs require.

Conclusion

If your company has made significant investments in enterprise and laboratory tools, technologies and solutions but you’re not reaping the ROI or seeing the improvements in productivity, efficiencies and data management that such investments promised, the paperless lab concept deserves serious consideration. Not only can such an integrated, seamless environment improve compliance and quality by eliminating data silos and connecting islands of information across the enterprise, but it can free up your scientists and laboratory professionals to spend more time on value-added research, new product development or other activities that bring revenue to your business.

Susan Najjar is the Director of Marketing for the Informatics business at Thermo Fisher Scientific, 22 Alpha Road, Chelmsford, MA. She may be reached at 781-287-4869. For more information, please visit www.thermoscientific.com/paperlesslab or contact marketing.informatics@thermofisher.com.

Looking for quick answers on food safety topics?

Try Ask FSM, our new smart AI search tool.

Ask FSM →