Detection and Inspection

Finding and removing foreign material in food is a challenge science is tackling.

ARTICLES

Inspection Systems

Some pointers on choosing metal detection systems to keep food safe from adulteration

While meeting FDA, SQF, CFIA and BRC requirements is important, regulatory agencies are no longer judge and jury in this world of social media

July 13, 2020

Preparing for food inspections 24/7

Get more peace of mind with these three steps

July 1, 2020

GEA OxyCheck cleared to enter the U.S. market

GEA receives FDA approval for sensor technology used to monitor food packaging quality

June 12, 2020

IMAGE GALLERIES

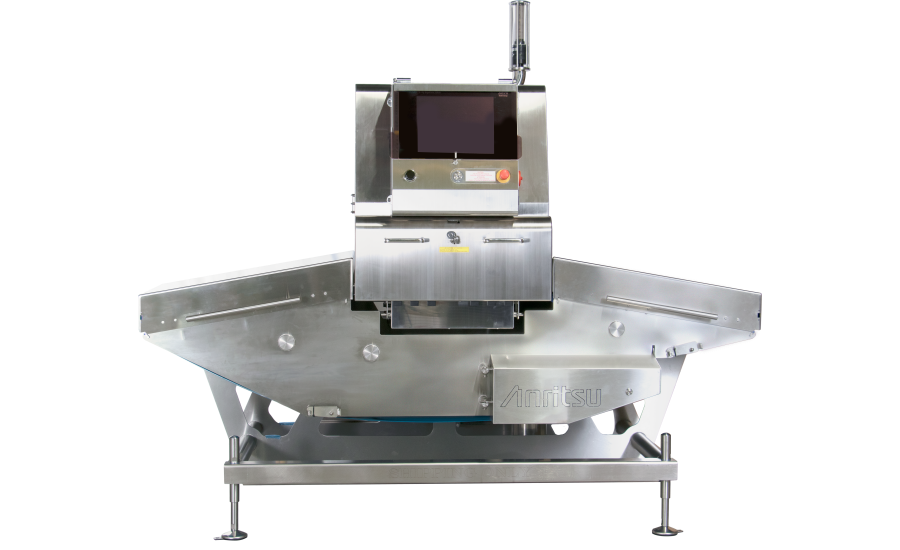

Slideshow: Foreign material detection and product inspection

Equipment, technology and more featured in the "Foreign material detection and product inspection" article.

Get our eMagazine delivered directly to your inbox

Stay in the know on the latest science-based solutions for food safety.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing