Core to any food manufacturer’s food safety/Hazard Analysis and Critical Control Points (HACCP) plan are the facility’s prerequisite programs. The foundation of each prerequisite program is its corresponding Standard Operating Procedures (SOPs).

By definition, an SOP is a set of written instructions that document a food manufacturer’s routine or repetitive activity. Specific to food manufacturing plants, the term SOP is commonly applied to production, manufacturing and support area processes, jobs or activities. For all sanitation-related processes, jobs or activities, the term SSOP (Sanitation SOP) is reserved.

The development and use of SOPs/SSOPs are integral parts of a successful food safety, quality and sanitation system (see Figure 1), as they provide individuals with the information required to properly perform their jobs. Furthermore, the use of SOPs and SSOPs promotes quality through consistent implementation of a process, task or job. Also, if clearly written, SOPs and SSOPs can minimize miscommunication and variation between individuals or organizations.

The development and use of SOPs/SSOPs are integral parts of a successful food safety, quality and sanitation system (see Figure 1), as they provide individuals with the information required to properly perform their jobs. Furthermore, the use of SOPs and SSOPs promotes quality through consistent implementation of a process, task or job. Also, if clearly written, SOPs and SSOPs can minimize miscommunication and variation between individuals or organizations.

The term SOP may also be used interchangeably with “protocol,” “job instruction” or “work instruction.”

Implications of a Food Recall

The importance of the development and use of food plant SOPs/SSOPs cannot be overstated. For example, according to the most recent U.S. Food and Drug Administration’s Reportable Food Registry annual report (fiscal year, September 2011–August 2012),[1] 37.9 percent of all food recalls were due to undeclared allergens. In the course of the investigations, the true cause of these recalls was traced to either an SOP/SSOP that did not exist or was inadequate, or to a failure to adhere to one or more of the applicable procedures, including:

• Good Manufacturing Practices

• Label review

• Residual chemical testing

• Raw material testing

• Sanitation

• Housekeeping

• Product process design

• Rework

• Hold and release

• Recall procedures

• Storage

• Training

• Product sequencing

• Traceability

• Supplier approval

In addition to creating harm and generating bad publicity, recalls are expensive: the average cost associated with these allergen-related SOP failures has been estimated at $10 million per recall.

Benefits of SOPs

In addition to helping promote food safety and prevent food recalls, SOPs can do the following:

• Serve as the basis for implementing an effective program to include employee training as well as a tool for on-the-floor coaching and development.

• Identify control points, as well as their limits, to control and validate the process. Corrective actions and preventive actions can be identified in order to address each.

• Establish time, labor and material requirements for a job or task.

• Be used as checklists by internal audit team members when auditing the plant’s programs and procedures.

Ultimately, the benefits of a valid SOP are reduced work effort, along with improved comparability, credibility and legal defensibility.

Developing and Maintaining SOPs/SSOPs

SOPs and SSOPs should adhere to the following food industry best practices.

Key Sections

The SOP/SSOP must be formatted in such a way that it provides all pertinent information so that an employee with some knowledge of the area, equipment and tools can read and perform the functions of the task both safely and effectively.

• Title Page

Clearly identifies the procedure name, an identification number, date of issue and/or revision and the name of the applicable plant, division and department to which the SOP applies. Also included in this section are the signatures and signature dates of those individuals who prepared and approved the SOP. Electronic signatures are acceptable for SOPs maintained on a computerized database.

• Table of Contents

A table of contents is helpful for quick reference and location of specific information, changes or updates. It is especially important for lengthy or detailed SOPs/SSOPs.

• Introduction/Purpose

This section will describe the intention for the SOP/SSOP and allows the reader to better understand not only the “how” but the “why” as well. Included here are any applicable background information and an overview.

• Responsibilities

List of accountabilities for all stakeholders, detailed by position.

• Definitions

This section includes a list of terms, phrases, words or acronyms and their applicable meanings. Since the reader will already have some knowledge of the task or equipment, only uncommon and unfamiliar terms should be defined. For example, in a testing procedure, Listeria may not need to be defined, whereas in an environmental monitoring procedure, Listeria may require definition.

• Materials

Where necessary, list the materials, equipment, checklists and supporting documents required to complete the activity or task.

• Safety

Includes a list of any personal injury or loss-of-life warnings, such as confined space. This section should explain what will happen if the procedure is not followed or is followed incorrectly.

• Procedure(s)

Each process, task or step to be taken in sequence will be listed in this section. One SOP/SSOP document may contain several procedures for multiple processes or subprocesses.

• Training

List the training requirements for the SOP/SSOP as well as the frequency of training (i.e., one-time or annually).

• Documentation

Identify the forms to be used and reports to be written, as well as the data and record storage location and duration.

• Compliance Verification and Validation

Describe any control steps and provisions for review and/or oversight. Verification will include a periodic review of the SOP/SSOP and the corresponding activities. (Are we doing what we say we are doing?) Alternatively, validation will include a periodic review of the records, reports and other documentation. (Are the goals of the SOP being accomplished?) All deviations should be reported and trended, and a corrective action/preventive action plan developed to address each opportunity.

• References

List of all cited regulatory, company or facility references.

• Document Revision History

List of all reviews, updates and revisions made to the SOP/SSOP.

Content

SOPs and SSOPs should be clearly worded so as to be readily understandable by a person knowledgeable about the general concept of the procedure. Use diagrams, flow charts, pictures and computer screen shots to help break up long sections of text and to summarize a series of steps for the reader. These visual aids especially help in the training of the SOP/SSOP.

Care must be taken to include all necessary information without becoming too detailed. Below is an example with an adequate level of detail and another with too much detail, making the SOP/SSOP overwhelming to the user.

• Good example: “Step 4. Rinse thoroughly with warm water.”

• Poor example: “Step 4. Rinse thoroughly using the sanitation station located on the back wall, near the door, with boosted pressure, warm water. Use the blue hose fitted with a 2–4 gpm, 15-degree fan-spray nozzle. Turn on main valve at sanitation station.”

Development Process

When developing an SOP/SSOP, a subject matter expert (SME) should prepare a written draft of the procedure. This draft is then reviewed by other plant or area experts. The purpose of this review is to solicit comments, suggestions and ideas for improvement and clarification.

Once the SOP/SSOP has been drafted, the content must then be verified. This is best accomplished by having the SME “walk” through the procedure, on the floor, taking into consideration all key parameters (e.g., time, equipment speed, sample location, etc.). Update the SOP/SSOP with all necessary changes. Pictures, diagrams, flow charts and computer screen shots should be inserted at this time.

Once the SOP/SSOP is in final draft form, an equipment or process expert, such as a training supervisor, should perform the procedure as written. If possible, to best identify any and all gaps, conduct more than one expert review. These experts will then provide the final updates and refinements required to complete the SOP/SSOP.

When finalized, the SOP/SSOP should then follow the appropriate approval process, as identified in the company’s policy, and be published.

Revisions and Reviews

An SOP/SSOP is an ever-changing, “living” document. As such, in an effort to continuously improve a process or task, updates are required. Indeed, improvements should be actively sought and changes often made. These must always be tracked and communicated effectively.

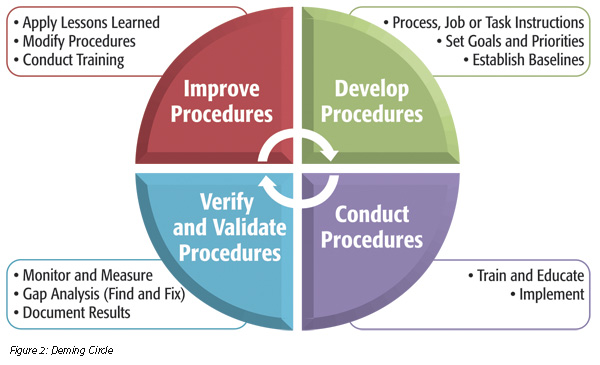

This “continuous improvement” cycle can best be described by a variant of the Deming circle, also known as plan, do, check, act (PDCA).[2] The Deming circle is an iterative, four-step method used for the control and continuous improvement of processes (Figure 2).

This “continuous improvement” cycle can best be described by a variant of the Deming circle, also known as plan, do, check, act (PDCA).[2] The Deming circle is an iterative, four-step method used for the control and continuous improvement of processes (Figure 2).

The PDCA steps for each successive Deming circle include the following four phases:

Plan (Develop Procedures)

Develop the SOPs and SSOPs, establishing the objectives and processes necessary to deliver the desired results. This will, in turn, establish goals, priorities and baselines to achieve. Establishing these expectations makes completeness and accuracy of the SOP/SSOP a part of the targeted improvement.

Do (Perform Procedures)

Perform the SOPs/SSOPs. In other words, execute the plan, conduct the process and make the product. Collect data for charting, trending and analysis.

Check (Verify and Validate Procedures)[3]

Verify and validate the SOPs/SSOPs by studying the actual results, as measured in the “Do” section. Compare these results with the targets or goals from the “Plan” section. Look for deviations between the development and the execution of the SOP/SSOP. Charting data can make it much easier to see trends over several Deming cycles.

Act (Revise and Improve Procedures)

For each significant difference between actual and planned results, once the root cause has been determined, develop a corrective action/preventive action (CAPA) plan. Determine where to apply changes that will include improvement of the process or product. If, after one or two passes through the Deming circle, the process does not improve, further refine the CAPA plan to include more detail in the next iteration of the cycle(s). Alternatively, greater attention may be required in a different stage of the process.

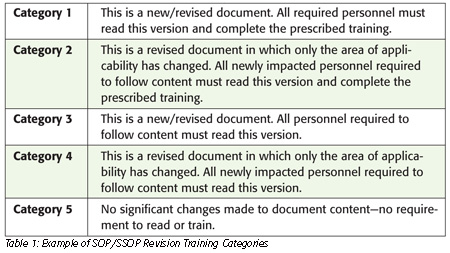

SOP/SSOP revisions and updates should be categorized so that all the stakeholders understand the amount of change that has occurred as well as the extent of employee training required with the changes (Table 1).

SOP/SSOP revisions and updates should be categorized so that all the stakeholders understand the amount of change that has occurred as well as the extent of employee training required with the changes (Table 1).

Document Control

Document control is the process of initiating, updating, changing and “expiring” company documents. All documents and records should be maintained in either an electronic or manual system.

At a prescribed time (i.e., immediately after production, weekly, etc.), all documents and records will be collected. Once compiled, all of the documents and records will then be stored in a short-term archive, in an area that will allow easy access for reference as needed.

As archived records begin to exceed the maximum length of time for short-term storage, they will be moved to a long-term storage location for a minimum of 2 years or shelf life plus 1 year, whichever is longer. Local, state and federal regulations as well as customer requirements may prescribe a longer duration.

Disposal of expired documents and records should occur on a scheduled basis and in accordance with an established policy.

Access

Easy employee access to each SOP and SSOP is a must. Therefore, the most current version of the SOP and SSOP must be readily available. Access can be in the form of either a printed manual or electronic access. If a printed manual is used, procedures and practices must be in place that ensure the manual is controlled and that the updates are current.

For new employees or for employees working in an unfamiliar or new area, having a physical copy in hand may be especially useful. This copy can be used as quick reference for a new work assignment or for coaching activities.

Whether considered a protocol, work instruction or job instruction, SOPs and SSOPs must be integral and foundational parts of all food manufacturing facilities’ food safety program.

Tim Lombardo is the lead staff scientist (food safety and microbiology) for Covance Laboratories, nutritional chemistry and food safety division. A graduate of Sam Houston State University in Huntsville, TX, he has held many key positions in the food manufacturing industry, including production, quality and sanitation positions at factory and corporate levels. With Covance, Tim provides food safety consulting support to food manufacturers in all aspects of food safety. He can be reached at tim.lombardo@covance.com.

References

1. FDA Foods and Veterinary Medicine Program. 2012. The Reportable Food Registry: Targeting Inspection Resources and Identifying Patterns of Adulteration. Second annual report: September 8, 2011–September 7, 2012.

2. Moen, R. and C. Norman. 2010. Circling back: Clearing up myths about the Deming circle and seeing how it keeps evolving. Quality Progress Magazine November.

3. Baldus, K. and V. Deibel. 2007. How to validate your GMP and prerequisite programs. Food Safety Magazine 13(2):12–17.

Food Plant SOPs: The Backbone of Your Food Safety System