Color-coding is an important part of any food safety program. Not only does it help prevent cross-contamination due to pathogens, allergens and foreign contaminates, color-coding has a variety of other uses. With the number of governmental regulations growing, it is essential that food processing facilities stay on top of the current trends and best practices to be market leaders. Implementing a color-coding program is a great way to help accomplish that.

Here are the five things that you should know about color-coding:

1. All types of food processing facilities can benefit from color-coding

2. Color-coding helps prevent cross-contamination in food processing facilities

3. Color-coding helps distinguish critical zones and control points

4. There is currently no standard set of rules for color-coding, just best practices

5. Color-coding programs are looked upon favorably by auditors and customers

1. Benefits All Food Processing Facilities

Any food processing center can benefit from color-coding, which helps keep work areas sanitary and organized. There are some industries that can especially benefit from color-coding. Not surprisingly, these industries tend to carry higher risks and take more precautions.

.jpg) Some of the industries that can benefit the most from color-coding are:

Some of the industries that can benefit the most from color-coding are:

• Meat/poultry

• Seafood

• Dairy

• Produce/raw ingredients

• Baking/snack

• Confectionery

• Beverage

• Vineyard/winery

These industries are most concerned with preventing cross-contamination and cross-contact, especially when dealing with pathogens, allergens and other foreign contaminates, and complying with strict U.S. Food & Drug Administration (FDA) and U.S. Department of Agriculture (USDA) regulations. In light of the recent increase in food recalls, it is more important than ever to be vigilant in food processing facilities.

Color-coding can do more than just help prevent cross-contamination, such as aiding organizational efforts. When everything has a place, and everyone knows where that place is based on an object’s color, it’s easy to keep tools put away. For a large facility, color-coding can separate tools by shift or by area. For smaller operations, a single color could be used per employee or employee role.

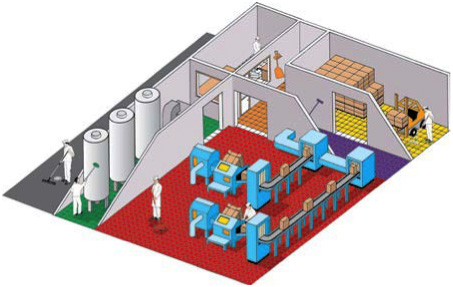

Color-coding goes beyond cleaning and material-handling tools. All kinds of accessories can be color-coded to help ensure complete understanding. Hair nets, footwear, clothing, gloves, mats, bins and even tape can be color-coded to make distinguishing between different zones easy.

Color-coding goes beyond cleaning and material-handling tools. All kinds of accessories can be color-coded to help ensure complete understanding. Hair nets, footwear, clothing, gloves, mats, bins and even tape can be color-coded to make distinguishing between different zones easy.

Color-coding has a number of benefits to offer any food processing facility, especially when it is implemented effectively.

2. Prevents Cross-Contamination

Color-coding is an easy way to visually separate work areas and prevent cross-contamination. Facilities with cross-contact concerns with allergens should particularly consider color-coding to lower that risk. The threat of recalls is always present, especially with facilities that contain allergens.

Color-coding can help decrease the risk of contamination that leads to recalls. Color-coding developed using the guidelines of Hazard Analysis and Critical Control Points (HACCP), a management system in which food safety is addressed through the analysis and control of biological, chemical and physical hazards from raw material product, procurement and handling, to manufacturing, distribution and consumption of the finished product. Control measures are used to “prevent, eliminate or reduce a significant hazard” in this system. Color-coding is an excellent example of a control measure.

Cross-contamination is prevented by keeping foods that transfer bacteria separate or by keeping allergens separate. For example, we all know raw meat should never come into contact with processed meat, so you keep them separate. The simplest way to do this is to color-code the food processing facility. When a facility has a color-coded program in place, it becomes much easier to distinguish between sections. For example, raw meat zones can be color-coded red and processed areas green.

Sample Color-Coding Systems:

Preventing Functional Cross-Contamination:

Red: Raw Meat

Green: Processed or Cooked Meat

Preventing Departmental Cross-Contamination:

Blue: Seafood

Yellow: Chicken

Preventing Allergen Cross-Contamination:

White: Milk Green:

Soy Yellow: Wheat

3. Marks Zones and Critical Control Points

Just about every food processor knows that complying with food safety regulations from FDA and other regulatory bodies is a vital aspect to the success of their overall operation. Without achieving this compliance, it would be fairly difficult to run an effective food processing program. The list of recalled food products seems to grow every day—many the result of some sort of cross-contamination—and those recalls can cost millions of dollars. The old adage, “better safe than sorry,” comes into play when talking about protecting against recalls. Color-coding is one simple method to help keep your food processing operation as safe as possible.

One of the most important measures to come out of recent FDA regulations is HACCP, which is a preventive approach to the identification, evaluation and control of food safety hazards that may cause illness or injury when not properly controlled.

Put simply, HACCP is a measure designed to help control the threat of cross-contamination from biological, chemical and physical agents. According to FDA, “any action or activity that can be used to prevent, eliminate or reduce a significant hazard” is considered a control measure. Color-coding is an excellent example of a control measure.

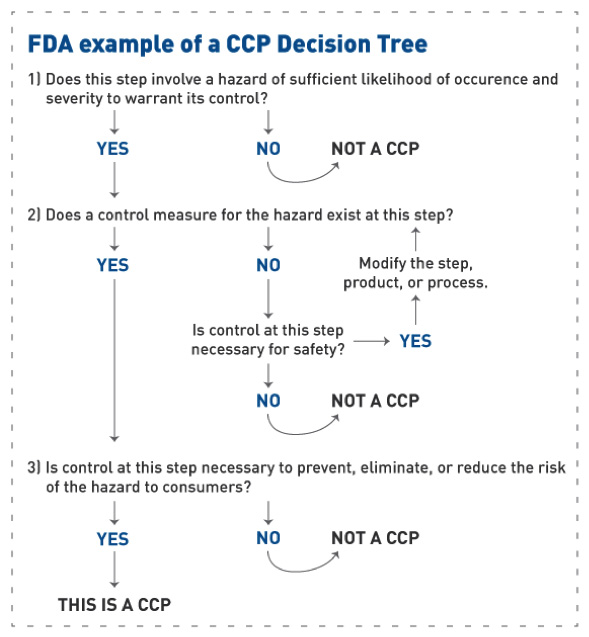

Once potential food safety hazards are identified, CCPs can be documented. FDA defines a CCP in a food manufacturing process as “a step at which control can be applied and is essential to prevent or eliminate a food safety hazard or reduce it to an acceptable level.” Knowing where the critical control points exist in a food production process is essential to designing an effective HACCP plan.

Once potential food safety hazards are identified, CCPs can be documented. FDA defines a CCP in a food manufacturing process as “a step at which control can be applied and is essential to prevent or eliminate a food safety hazard or reduce it to an acceptable level.” Knowing where the critical control points exist in a food production process is essential to designing an effective HACCP plan.

Included in the many HACCP compliance resources available from the FDA is an example of a decision tree to help a food processing operation identify CCPs, seen below. Using a decision tree like this is not a mandatory part of the process, but it is valuable as a tool to facilitate the development of a thorough food safety program.

Since color-coding is a control measure, color-coding zones often coincide with CCPs or groups of CCPs. For instance, a color zone may be assigned to an area where raw meat exists in a facility, since raw meat poses increased risks of bacterial contamination. There may be several CCPs that require other control measures within that one color zone, such as testing for contaminants or refrigeration of the raw meat prior to processing. Once the meat has been cooked, a different color may be assigned to the zone following the raw meat area to prevent bacterial cross-contamination of the finished product. For this purpose, color-coding is an excellent and simple way to visually confirm that equipment is in the appropriate critical zone in a food processing facility.

When color-coding is implemented, it is easily apparent which zones are which, and what they represent. Because of this instant recognition, separating contaminated food before it goes out to the public becomes easier. And we all know that internal recalls (and no recalls at all) are less costly than public recalls.

4. Has Established Best Practices

While FDA does not currently have any standard set rules to follow when it comes to implementing a color-coding program, there are some common best practices that can optimize the process.

Here are some ideas to help you design an effective color-coding program:

Keep your color-coding system simple—Limiting the number of colors you use will go a long way towards simplifying the process. Too many times, people get bogged down with the idea that every line and every single process has to have a different color. This is not the case. Try to have a different color only when cross-contamination is a concern at a CCP in the process. Those points where control is not needed could potentially use the same color, since cross-contamination is not a threat. If too many colors are used, the process becomes confusing and less effective.

Pick logical colors for each area—Making the transition to a color-coding system should be as seamless as possible. To keep confusion low when stepping into this system, try to pick colors that make the most sense in each area. For example, certain colors might make sense for certain areas in your food processing facility, such as red for raw meat or yellow for wheat. Do what is most logical for your facility. Also, make sure that it makes sense to both managers and employees. If everyone is on the same page, the transition should run smoothly.

Pick logical colors for each area—Making the transition to a color-coding system should be as seamless as possible. To keep confusion low when stepping into this system, try to pick colors that make the most sense in each area. For example, certain colors might make sense for certain areas in your food processing facility, such as red for raw meat or yellow for wheat. Do what is most logical for your facility. Also, make sure that it makes sense to both managers and employees. If everyone is on the same page, the transition should run smoothly.

Avoid complicated color assignments—Having customized tools, like a different colored handle than the broom, might seem like a great idea to help differentiate zones. However, it could also lead to confusion. If you mix and match handles and brushes, the end result might be chaos. Say you have a red broom with a green handle. Now, you have the problem of trying to figure out if it goes in the green zone or the red zone. Save everyone the confusion, and stick to one color per zone. Instant recognition is the key to keeping confusion to a minimum. You should be able to look quickly and determine which zone is which. Remember, color-coding is supposed to solve confusion, not add to it.

Roll out the color-coding program at one time—This goes back to avoiding confusion. If you try to incorporate the new system in with the old one, people are just going to be confused. It’s best to start the program all at once. It might be more difficult in the beginning, but it will be worth it in the end. Also, having a definite end date to the old program and a definite start date for the new system will make the transition even smoother.

Good communication is key—Having everyone on the same page will help with starting your color-coding program. A good place to start is by discussing changes with shift managers, then rolling it out to employees. The mangers should have a good understand of the new system so they can address any questions or concerns employees might have. Offer a cheat sheet to employees that explains the color zones so they’ll have the information with them at all times.

Reinforce color-coding with good signage—When you’re starting a color-coding program, you don’t want any ambiguity in how it’s perceived. Make it absolutely clear what the program is, and when it is starting. The best thing to do is label every point in the process, in multiple languages if necessary.

Be sure your tools and storage areas match—Be sure the tools are stored in the same area where they are used to avoid confusion, cross-contamination and equipment loss. If the red tools are stored on a red bracket or red shelf, it is easy to see exactly where that tool should go when it isn’t in use. Having an organized storage area will be very helpful in maintaining the integrity of the color-coding system.

Follow through—Utilize the same documentation at point of use with the purchasing department and with the quality manager, so everyone is on the same page. Make sure all loose ends are tied up to further the success of the color-coding program. If the program is successful, your facility will be much safer.

5. Regulators and Auditors Love It

5. Regulators and Auditors Love It

If your business is food processing, you’re no stranger to government rules, regulations and auditors. Complying with federal food safety regulations is crucial to the success—and even the existence—of your operation. Keeping the auditor happy sometimes becomes a top priority (such as the day before the audit), because no one wants to deal with the time, money, and marred reputation of a production delay or facility shutdown. If you’re looking for ways to strengthen the food safety efforts at your operation, you need to know about color-coding—because we guarantee that your auditor does.

Even though color-coding is not a standard rule or even a requirement, it is a practice that regulatory authorities commonly favor. Regulatory agencies, like FDA and USDA, exist to provide guidance for food safety procedures and ensure compliance with laws relating to the safety of the nation’s food supply. One such law is the Food Safety Modernization Act (FSMA) that is intended to transform the U.S. food safety framework from a reactive damage control approach to more of a proactive prevention of foodborne illness crises. FSMA Section 103 requires food facilities to prepare written plans to evaluate hazards and implement effective preventive controls. It mandates several steps to ensure a true preventive approach to food safety.

Regulating authorities look favorably upon the practice of color-coding, because it is a method that can easily be documented and followed by employees. A color-coding program that is written into a HACCP plan essentially becomes part of the facility’s Standard Operating Procedures. A HACCP plan is a written outline that identifies potential food safety threats and CCPs. Color-coding adds an extra layer of preventive protection in addition to other food safety efforts such as hygienic building layouts and hygienic equipment. Programs that are easily documented are also more easily communicated to employees, and the employees’ adoption of food safety procedures is imperative to a program’s effectiveness.

Visiting authorities and customers will readily notice color-coding programs upon entering a processing facility, which is precisely why the approach is so effective. Segregating zones by colors offers quick visual confirmation that equipment is where it belongs and is not contributing to the unintentional transport of contaminants throughout the facility. When color-coding is utilized as part of a multifaceted approach to food safety, it adds credibility to the effectiveness of the operation for regulators and customers alike.

With the new laws and proposed guidelines surrounding food safety, prevention is the preferred approach by regulatory authorities. And in the long run, prevention is a better business practice than reactive damage control. The old saying about closing the barn door after the horse is out comes to mind when thinking about recalls; it’s better if a recall is prevented from happening in the first place.

News of recalls travels in the blink of an eye since the rise of social media. In that short time, your facility’s reputation can be irreparably damaged. To safeguard your operation from the negative publicity of a food safety crisis, it is imperative to prevent recalls before they happen. Monitoring any sort of cross-contamination threat inside the facility is fundamental, and color-coding is a simple way to keep those risks in check.

For more information, visit Remco at Remcoproducts.com.